Heat treatment furnace with controllable cooling rate and uniform workpiece surface oxidation

A technology of workpiece surface and cooling rate, which is applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve the problems of safety of people and objects from burns, uneven oxidation degree of workpiece surface, heat overflow, etc., and achieve the goal of surrounding materials and operations Safe operation, good heat treatment effect of the workpiece, and the effect of avoiding potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

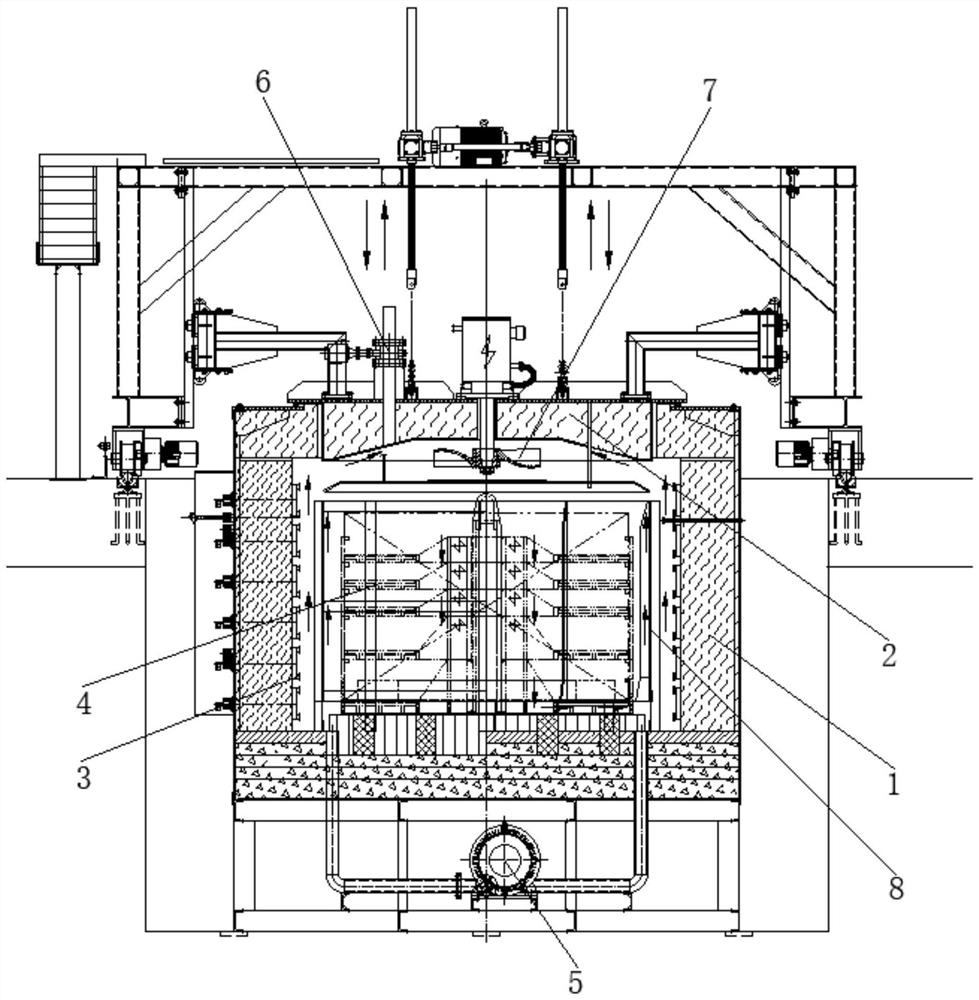

[0018] like figure 1 As shown, a heat treatment furnace with a controllable cooling rate and uniform oxidation of the surface of the workpiece includes a furnace body 1, a furnace cover 2 is arranged on the furnace body 1, and a heater 3 and a material rack 4 are arranged in the furnace body 1. , the bottom of the furnace body of the furnace body 1 is connected with a cooling air inlet system 5, the cooling air inlet system 5 includes an air inlet device and an air supply duct, the air inlet device is connected to the air supply duct, and the air supply duct communicates with At the bottom of the furnace chamber of the furnace body 1, an air inlet switch is arranged on the air supply duct, the air inlet device is a cooling fan, and the furnace cover 2 is connected with a pressure relief and gas outlet system 6, and the pressure relief gas outlet system 6 includes: A pressure relief pipeline connected to the furnace chamber of the furnace body 1 and running through the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com