Pretreatment cooling and waste heat utilization method for epoxy compound sewage

A sewage and propylene oxide technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of ineffective utilization of waste heat, poor working environment, and high maintenance costs. The effect of reducing daily inspection and maintenance costs, reducing energy consumption, and reducing energy consumption

Inactive Publication Date: 2012-04-11

CHINA PETROLEUM & CHEM CORP +1

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] 1. A large amount of waste heat has not been effectively utilized, resulting in a waste of energy;

[0007] 2. The pollutants in the sewage enter the atmosphere with fine water mist or water droplets, causing secondary pollution;

[0008] Direct contact with the air produces a large amount of calcium salt precipitates to block the packing or nozzle. The cleaning and maintenance of the packing or nozzle must be done manually. The working environment is poor, the labor intensity is high, and the daily maintenance cost is high.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

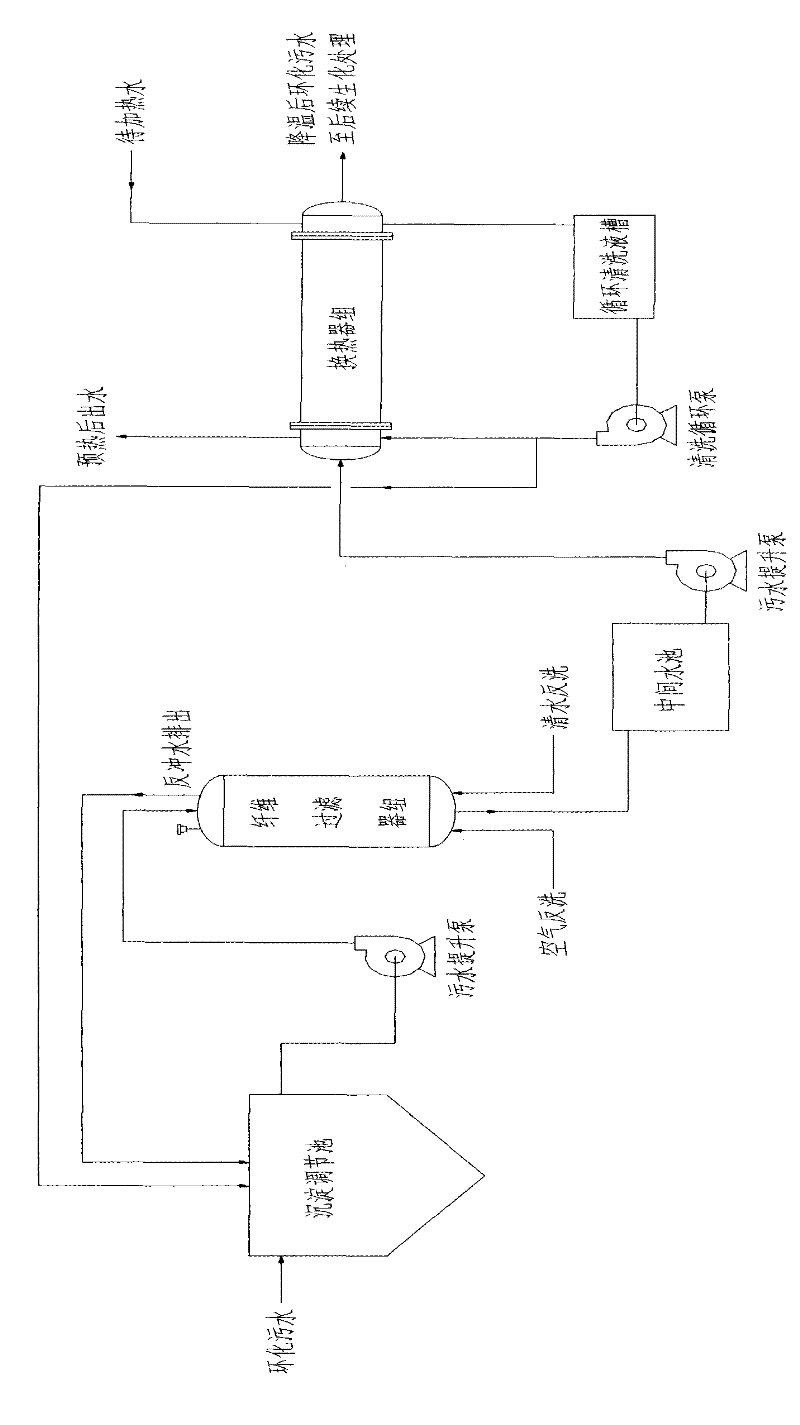

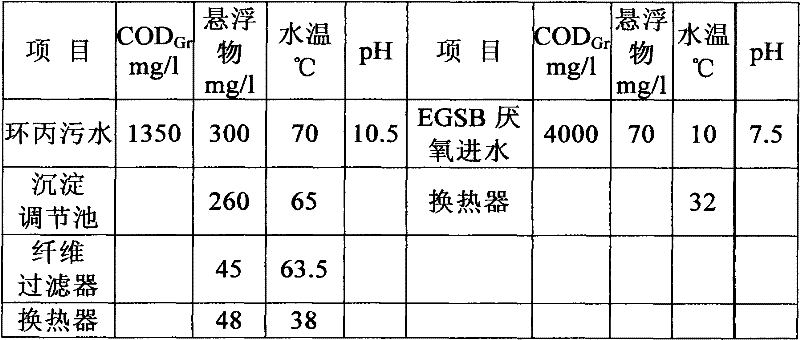

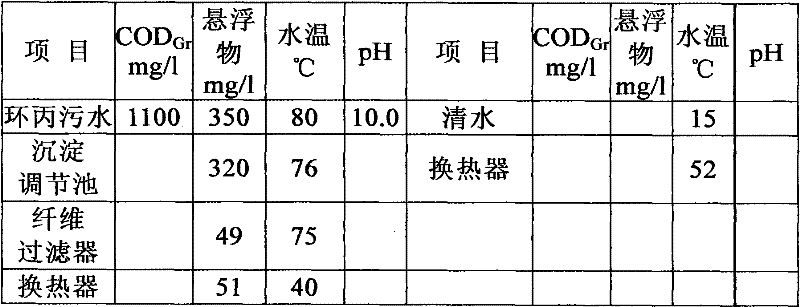

The invention relates to a closed cooling and waste heat utilization process for epoxy compound sewage. Epoxy compound raw water is adjusted and pumped into a fiber filter loaded with a soft filler, the suspended solid (SS) value of water discharged by the filter is controlled in a certain range, and the water is taken as primary water of a full-automatic heat exchange unit and fed into a heat exchanger; meanwhile, the pretreated sewage or clean water is taken as secondary side inlet water; after the sewage is subjected to heat exchange by the full-automatic heat exchange unit, the temperature of the epoxy compound sewage is reduced to a range which can be tolerated by mesophilic bacteria in biochemical treatment, and secondary side sewage is heated to a water inlet temperature required by an anaerobic treatment device; and if the clean water is adopted, the produced hot water can be used as boiler make-up water, domestic hot water, heating and air conditioning hot water and the like according to the water quality of the clean water. The process has the characteristics of capability of effectively utilizing waste heat energy, no secondary pollution, continuous and stable operation, low overhaul and maintenance cost and the like.

Description

technical field [0001] The invention relates to the technical field of industrial wastewater treatment, in particular to a method for pretreatment and cooling of epoxy compound sewage and waste heat utilization. Background technique [0002] Epoxides (mainly propylene oxide and epichlorohydrin) are important propylene derivatives and are the main raw materials for the production of polyether polyols. At present, the chlorohydrin method is still used in the production of a large number of epoxy compounds in China, which has the advantages of short process, high production safety and low construction cost, but at the same time has the disadvantages of corrosion and serious pollution. [0003] The sewage produced by the production of epoxy compounds by the chlorohydrin method (hereinafter referred to as the cyclization sewage) has high temperature (60-80°C after flash evaporation and heat exchange), high pH (10-12), high salt (CaCl 2 Concentration of 3.5% to 4.0%), high suspen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/00

Inventor 曹爱兵徐湘靳娇陈静君

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com