Method for extracting fish scale collagen peptide powder and hydroxyapatite

A fish scale collagen and hydroxyapatite technology, applied in chemical instruments and methods, animal/human protein, specific peptides, etc., can solve problems such as long hydrochloric acid immersion time, harmful substances in fish scales, complicated process routes, etc., to avoid violent The effect of chemical reaction, low production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

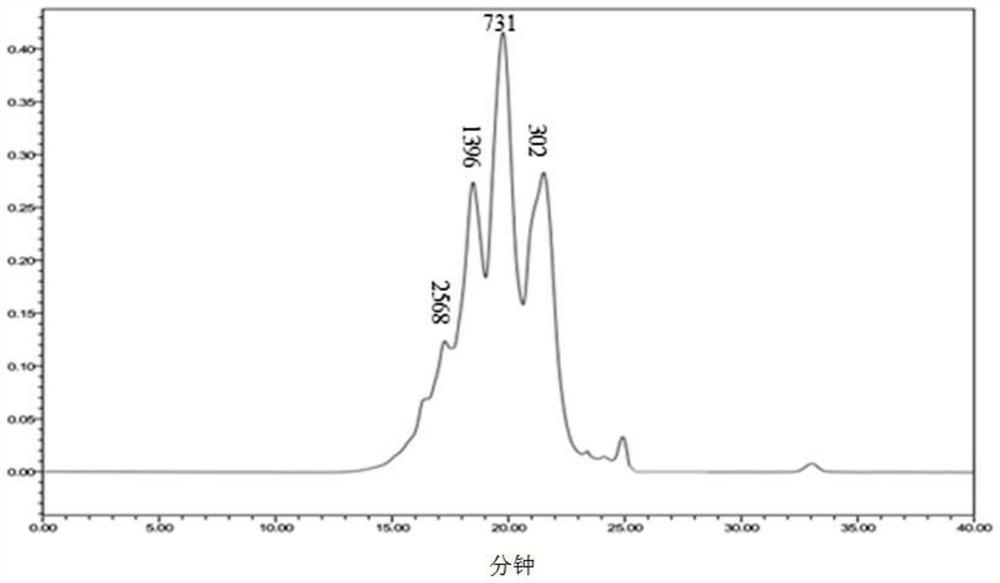

Image

Examples

Embodiment 1

[0042] Embodiment 1, a kind of method for extracting fish scale collagen peptide powder and hydroxyapatite, carries out following steps successively:

[0043] 1), washing (this is conventional technology):

[0044] Wash and remove impurities from fish scales;

[0045] 2), steam explosion treatment:

[0046] Put the washed fish scales obtained in step 1) into the explosion chamber of the steam explosion machine, carry out steam explosion treatment under the pressure of 0.6MPa, hold the pressure for 1min, and take out after pressure relief;

[0047] 3), hot water extraction:

[0048] Add 10 times the weight of water to the steam-exploded fish scales obtained in step 2), shake at a constant temperature of 50° C. for 2 hours, and rotate at a speed of 125 r / min; obtain fish scale protein extracts;

[0049] 4), enzymatic hydrolysis:

[0050] First adjust the pH of the fish scale protein extract to 8, then add Alcalase alkaline protease (Novozymes, the enzyme activity is 3.0AU / g)...

Embodiment 2

[0059] Embodiment 2, a kind of method for extracting fish scale collagen peptide powder and hydroxyapatite, carries out following steps successively:

[0060] 1), washing:

[0061] Wash and remove impurities from fish scales;

[0062] 2), steam explosion treatment:

[0063] Put the washed fish scales obtained in step 1) into the explosion chamber of the steam explosion machine, carry out steam explosion treatment under a pressure of 1.0MPa, hold the pressure for 0.5min, and take it out after depressurization;

[0064] 3), hot water extraction:

[0065] Add 8 times the weight of water to the steam-exploded fish scales obtained in step 2), shake at a constant temperature of 50° C. for 2 hours, and rotate at a speed of 125 r / min; obtain fish scale protein extracts;

[0066] 4), enzymatic hydrolysis:

[0067] First adjust the pH of the fish scale protein extract to 7.5, then add trypsin (enzyme activity: 250U / mg) accounting for 1% of the weight of the fish scale after steam ex...

Embodiment 3

[0076] Embodiment 3, a kind of method for extracting fish scale collagen peptide powder and hydroxyapatite, carries out following steps successively:

[0077] 1), washing:

[0078] Wash and remove impurities from fish scales;

[0079] 2), steam explosion treatment:

[0080] Put the washed fish scales obtained in step 1) into the explosion cavity of the steam explosion machine, carry out steam explosion treatment under the pressure of 0.4MPa, hold the pressure for 3min, and take out after pressure relief;

[0081] 3), hot water extraction:

[0082] Add 12 times the weight of water to the steam-exploded fish scales obtained in step 2), shake at a constant temperature of 50° C. for 2 hours, and rotate at a speed of 125 r / min; obtain fish scale protein extracts;

[0083] 4), enzymatic hydrolysis:

[0084] First adjust the pH of the fish scale protein extract to 7.5, then add trypsin (enzyme activity: 250 U / mg) accounting for 1% of the weight of the fish scale after steam explo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com