Plastic sliding bearing

A sliding bearing and plastic technology, which is applied to sliding contact bearings, bearings, bearings in rotary motion, etc., can solve the problems of difficulty in meeting the technical requirements of vehicle chassis, increasing the production process of bearings, and large bearing friction torque, and achieving low production costs. , The effect of reducing friction torque and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the technical content of the present invention more clearly, the following embodiments are given for detailed description.

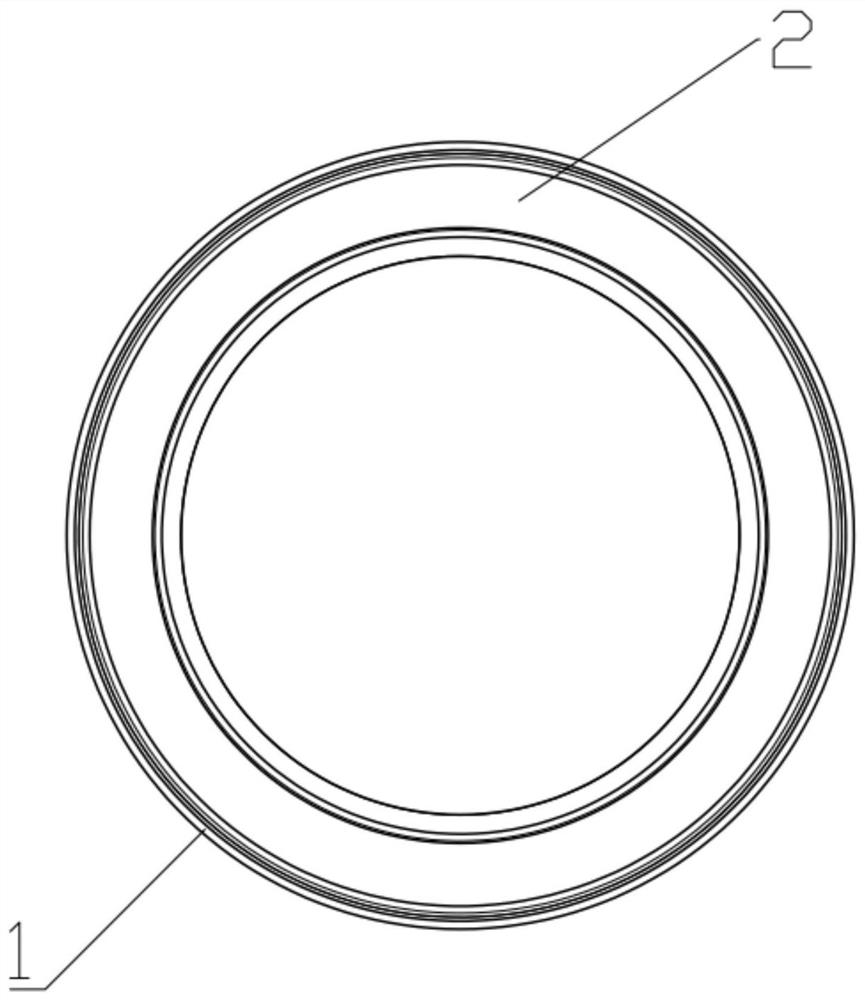

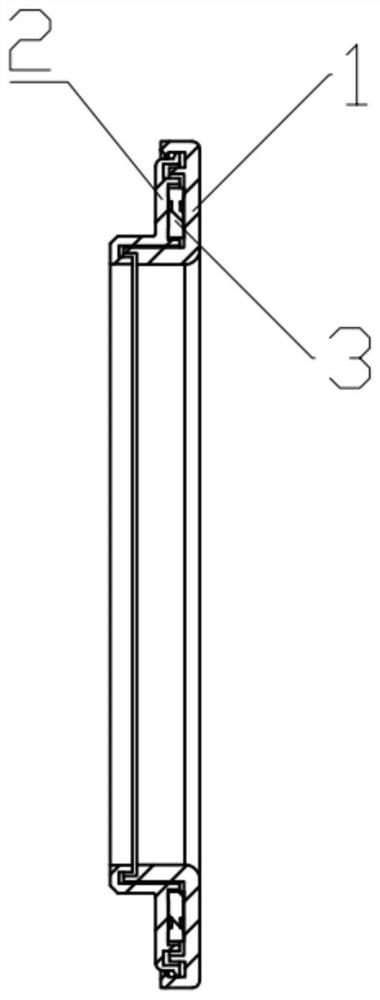

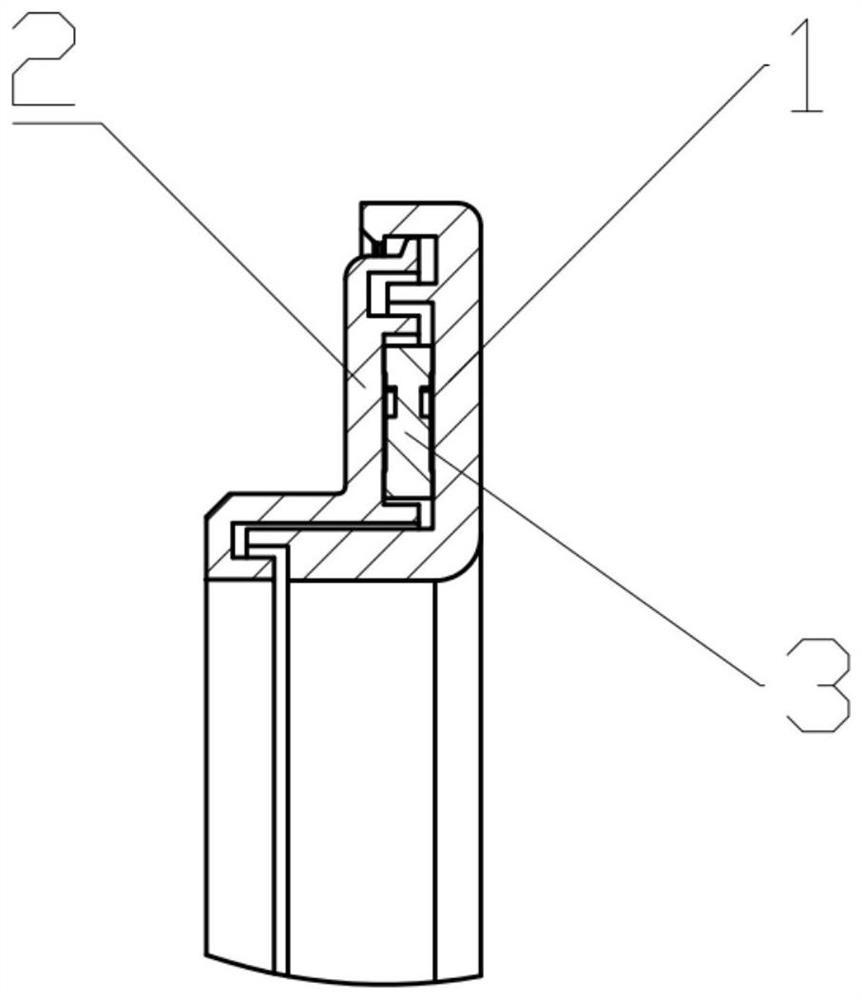

[0032] In one embodiment, as figure 1 , 2 , 3, the plastic sliding bearing includes a lower cover plate 1, an upper cover plate 2 and an annular gasket 3.

[0033] Among them, the lower cover 1 is as Figure 4 , 5 As shown, it includes an annular lower cover plate bottom 11, an outer insert groove 12 arranged at the outer peripheral end of the annular lower cover plate bottom 11, and an inner side wall 13 arranged at the inner peripheral end of the annular lower cover plate bottom 11;

[0034] Upper cover 2 such as Figure 10 , 11 , 12, it includes an annular upper cover plate base 21, an outer insert 22 arranged at the outer peripheral end of the annular upper cover plate base 21, and an inner ring hook 23 arranged at the inner peripheral end of the annular upper cover plate base 21; The outer insert 22 is embedded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com