Heat pump water heater and method for controlling exhaust temperature of compressor of heat pump water heater

A temperature control method and compressor exhaust technology, applied in the field of heat exchange, can solve problems such as abnormal startup, abnormal startup of the compressor, and inability to start, and achieve the effects of improving stability, reducing exhaust temperature and flexible adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

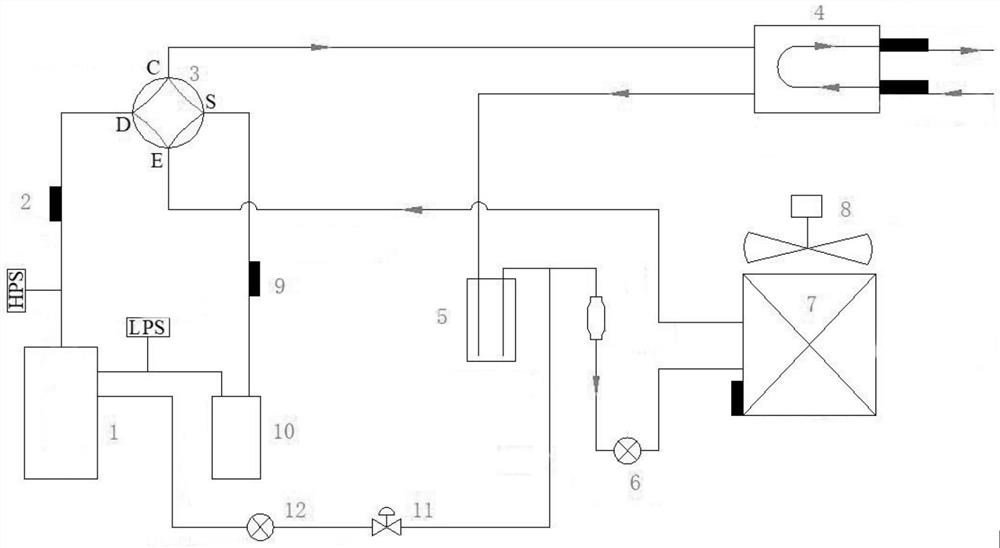

[0033] A control method of compressor discharge temperature, such as figure 1 As shown, it includes the main circuit for heat exchange and the auxiliary circuit for reducing the exhaust gas temperature. The refrigerant on the main circuit passes through the compressor 1, the four-way valve 3, the casing heat exchanger 4, the accumulator 5 and the fins in sequence. After the fin evaporator 7, it enters the gas-liquid separator 10 through the four-way valve 3 again, and then returns to the compressor 1. The pipeline connecting the accumulator 5 and the fin evaporator 7 is provided with a main circuit for controlling the flow of the refrigerant in the main circuit. One end of the auxiliary circuit is connected with the accumulator 5 and one end of the main circuit electronic expansion valve 6, the other end of the auxiliary circuit is communicated with the air inlet of the compressor 1, and the auxiliary circuit is installed with a liquid injection electronic expansion valve 12 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap