Dual-motor performance synchronous test device

A test device and dual-motor technology, applied in the direction of electromechanical devices, circuit devices, battery circuit devices, etc., can solve the problems of inability to test the performance of multiple motors and the serious energy consumption of multiple motor tests, so as to reduce the energy consumption of the test and reduce the Quantity, the effect of increasing the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

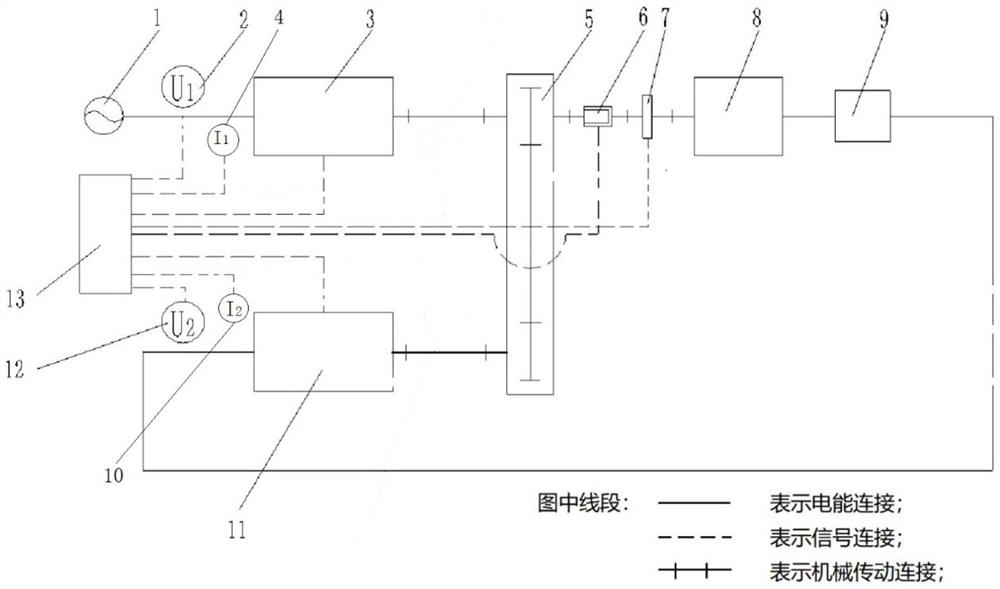

[0034] This implementation discloses a dual-motor performance synchronization test device, including: a power source 1, a power coupling device 5, a generator 8, an energy storage 9, and a controller 13;

[0035] The power output end of the power supply 1 is used to connect with the power input end of the first test motor 3 to provide power to the first test motor 3 for testing; the first power input end of the power coupling device 5 is used for Connected with the power output end of the first test motor 3, the second power input end of the power coupling device 5 is used to connect with the power output end of the second test motor 11, and the power output end of the power coupling device 5 be connected to the power input end of the generator 8 to couple the power of the first test motor 3 and the second test motor 11, and then transmit it to the generator 8 to drive the generator 8 to generate electricity;

[0036]The electrical energy input end of the accumulator 9 is conn...

Embodiment 2

[0040] The second embodiment is a preferred embodiment of the first embodiment. The difference between it and the first embodiment is that the specific structure of the dual-motor performance synchronization test device is expanded:

[0041] like figure 1 As shown, this embodiment discloses a dual-motor performance synchronization test device, including: a power supply 1, a power coupling device 5, a clutch 6, a generator 8, an energy storage 9, a controller 13, and a first voltage measuring device 2 , the second voltage measuring device 12, the first current measuring device 4, the second current measuring device 10, the torque and rotational speed measuring device 7; , the first power input end of the power coupling device 5 is used for connecting with the power output end of the first test motor 3 , and the second power input end of the power coupling device 5 is used for connecting with the power output end of the second test motor 11 The power output end is connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com