Preparation method of defect-free fast-switching dye-doped cholesteric liquid crystal intelligent window

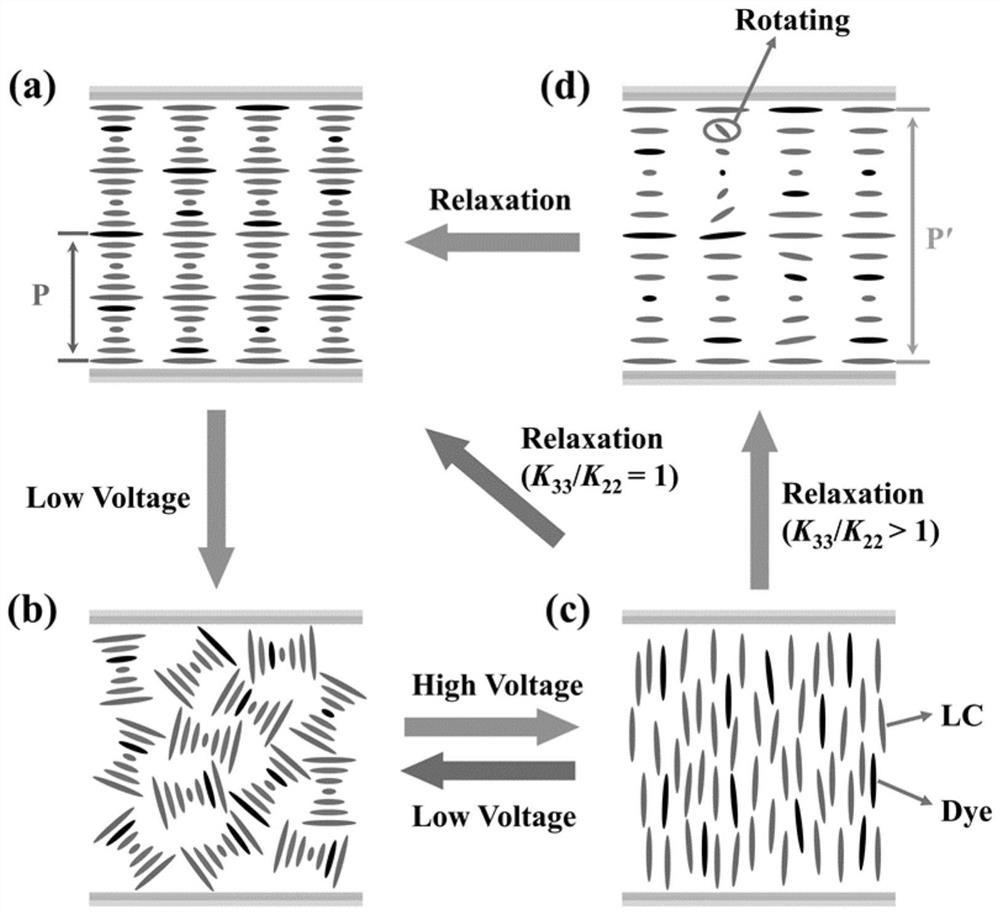

A cholesteric liquid crystal and fast switching technology is applied in the field of preparation of dye-doped cholesteric liquid crystal smart windows. The effect of eliminating grain defects, eliminating polarization dependence, and improving absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] refer to Figure 1-5 , a method for preparing a defect-free fast switching dye-doped cholesteric liquid crystal smart window, the specific steps are as follows:

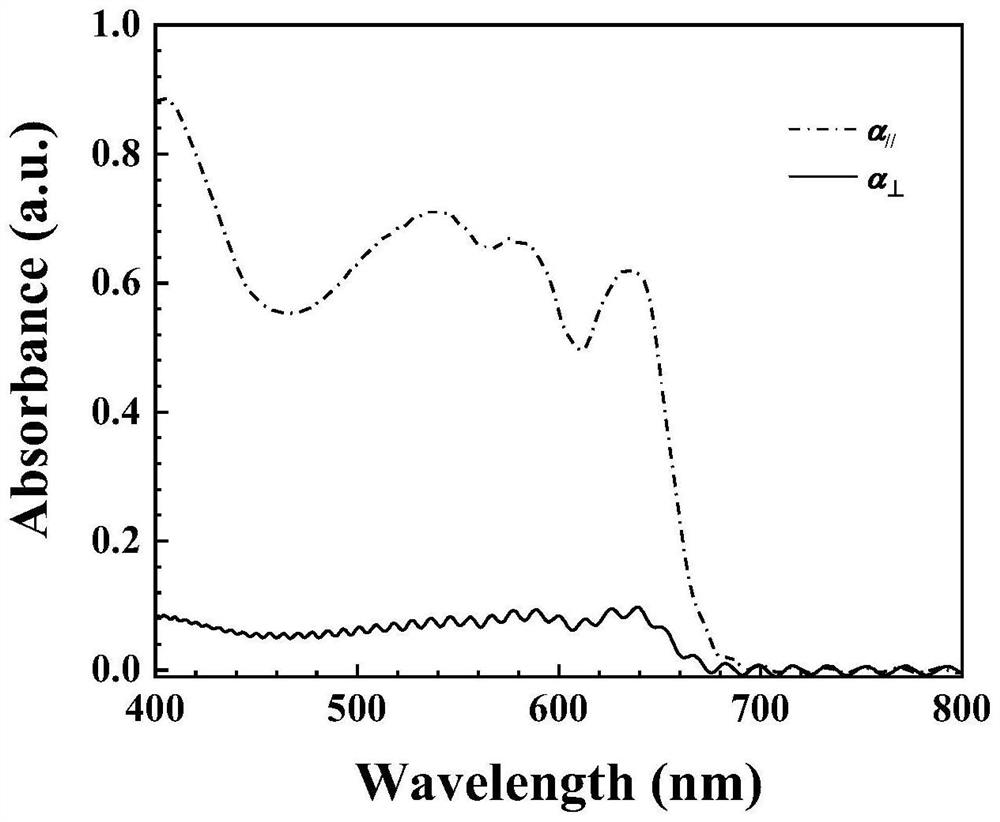

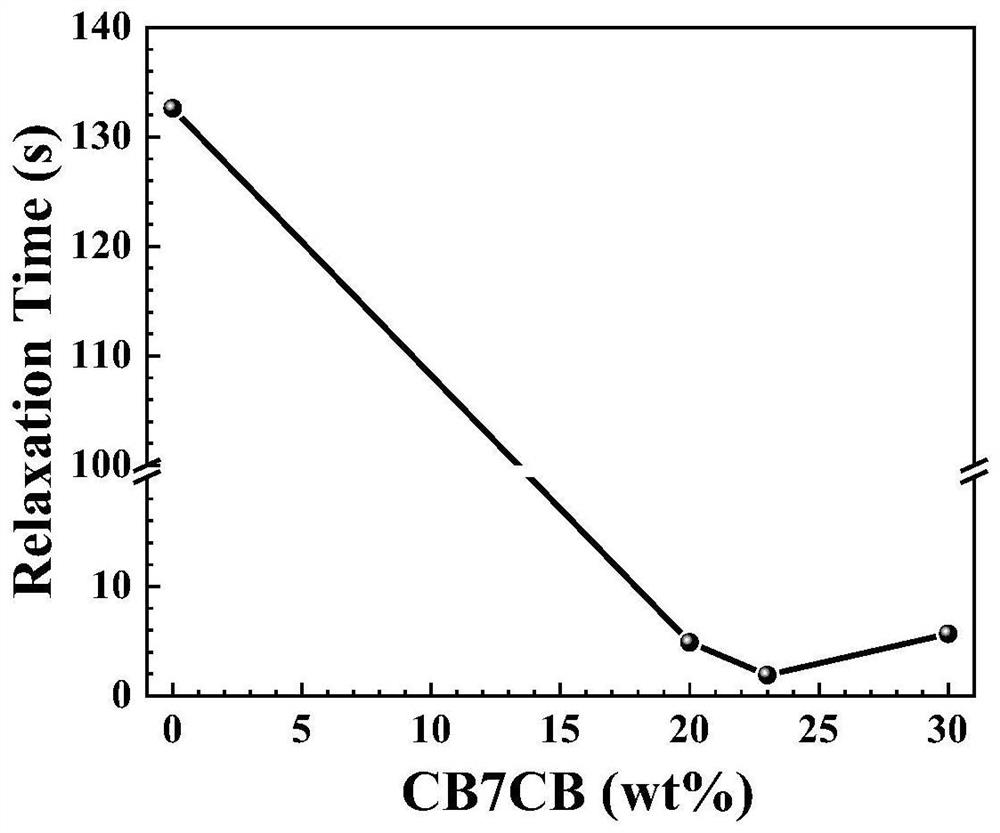

[0027] Step 1. Select liquid crystal BHR40200, curved liquid crystal CB7CB, chiral agent S811 and dichroic dye, and mix the above raw materials according to the following ratio of 93.5:0:7:3 to form a mixture;

[0028] Step 2. Place the mixture on a hot stage, place the mixture on the hot stage, and stir at a temperature of 90° C. for 20 hours, and then use a pipette to take a small amount of the mixture;

[0029] Step 3, using ODF or capillary action to inject the mixture into a liquid crystal cell with a cell thickness of 10 microns at a temperature of 90° C. through a crystal filling port, and sealing after cooling to obtain a dye-doped cholesteric liquid crystal smart window.

Embodiment 2

[0031] refer to Figure 1-5 , a method for preparing a defect-free fast switching dye-doped cholesteric liquid crystal smart window, the specific steps are as follows:

[0032] Step 1. Select liquid crystal BHR40200, curved liquid crystal CB7CB, chiral agent S811 and dichroic dye, and mix the above raw materials according to the following ratio of 73.5:20:5:1.5 to form a mixture;

[0033] Step 2. Place the mixture on a hot stage, place the mixture on the hot stage, and stir at a temperature of 90° C. for 20 hours, and then use a pipette to take a small amount of the mixture;

[0034] Step 3, using ODF or capillary action to inject the mixture into a liquid crystal cell with a cell thickness of 10 microns at a temperature of 90° C. through a crystal filling port, and sealing after cooling to obtain a dye-doped cholesteric liquid crystal smart window.

Embodiment 3

[0036] refer to Figure 1-5 , a method for preparing a defect-free fast switching dye-doped cholesteric liquid crystal smart window, the specific steps are as follows:

[0037] Step 1. Select liquid crystal BHR40200, curved liquid crystal CB7CB, chiral agent S811 and dichroic dye, and mix the above raw materials according to the following ratio of 70.5:23:5:1.5 to form a mixture;

[0038] Step 2. Place the mixture on the hot stage, place the mixture on the hot stage, and stir at a temperature of 100° C. for 24 hours, and then use a pipette to take a small amount of the mixture;

[0039] Step 3, using ODF or capillary action to inject the mixture into a liquid crystal cell with a cell thickness of 10 microns at a temperature of 100° C. through a crystal filling port, and sealing after cooling to obtain a dye-doped cholesteric liquid crystal smart window.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com