Turbine disc fatigue-creep reliability life evaluation method

An evaluation method, turbine disk technology, applied in sustainable transportation, constraint-based CAD, instruments, etc., can solve problems such as lifelessness, large deviation, prediction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Below in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail.

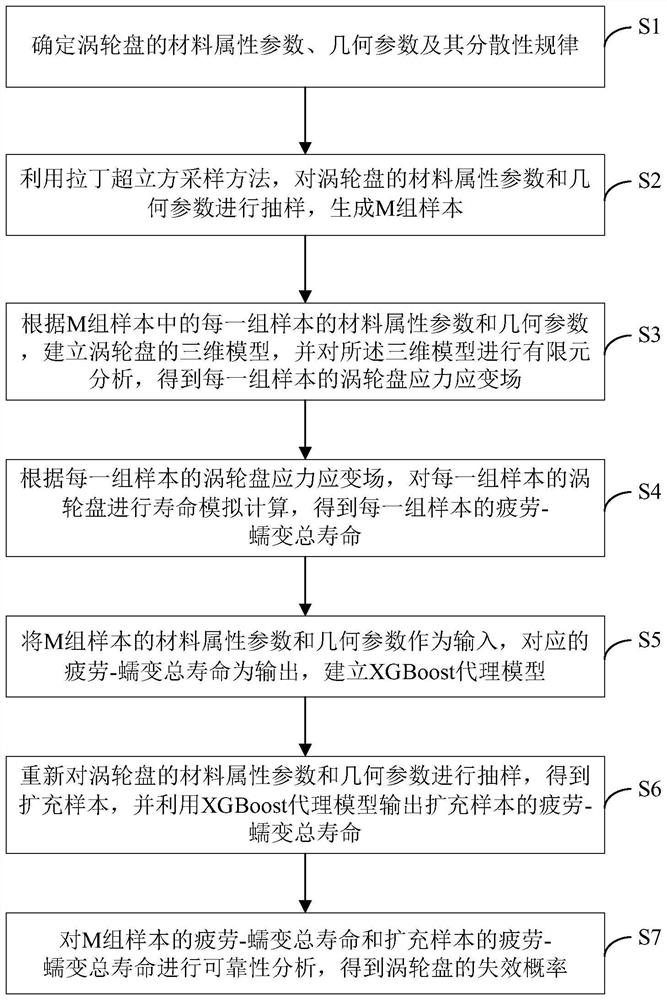

[0062] like figure 1 As shown, the embodiment of the present invention provides a fatigue-creep reliability life evaluation method of a turbine disk, which includes the following steps:

[0063] S1: Determine the material property parameters, geometric parameters and the dispersion law of material property parameters and geometric parameters of the turbine disk;

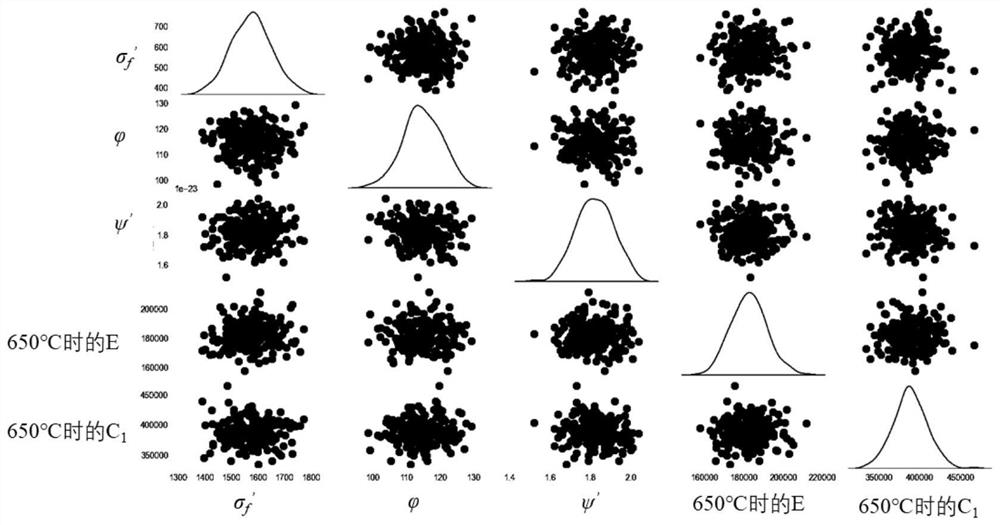

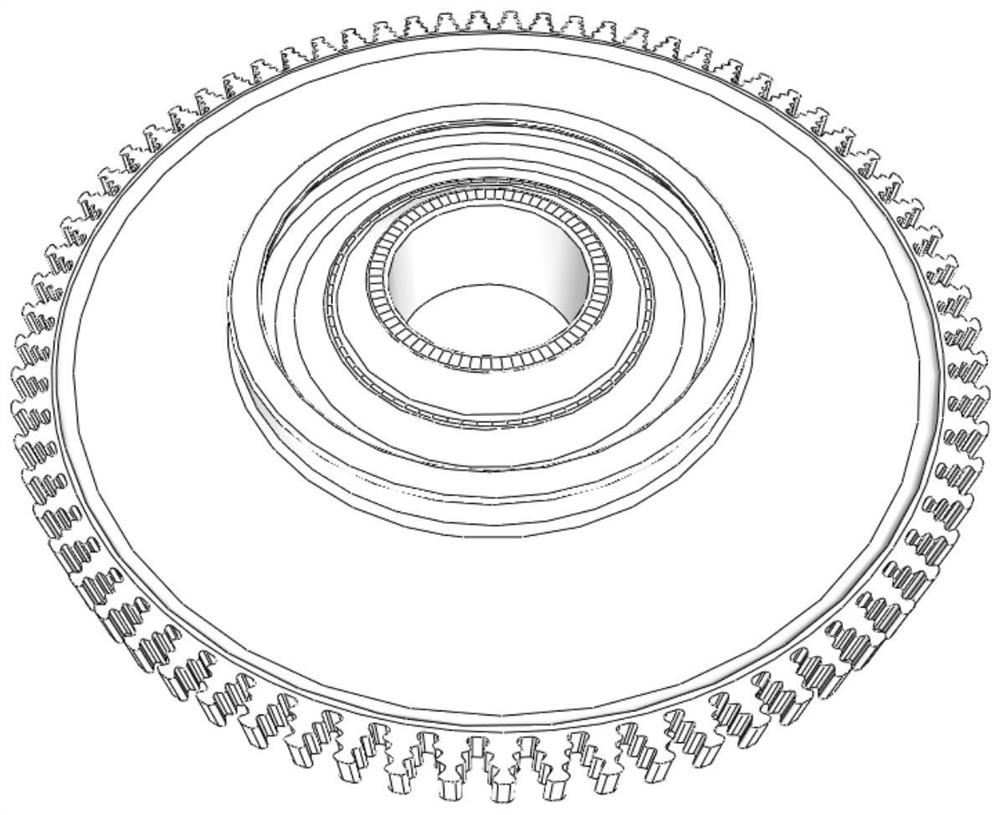

[0064] Material property parameters include Young's modulus, thermal expansion coefficient, thermal conductivity, creep constitutive model parameters, cyclic plastic constitutive model parameters, fatigue damage model parameters and creep damage model parameters at different temperatures, which can be based on existing parameters. The high temperature creep, fatigue and creep fatigue test results were obtained. The geometric parameters include the radius of the turbine disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com