O/D phase gel as well as preparation method and application thereof

A gel and polyglycerol technology, applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of unstable viscosity, difficulty in selecting thickeners, and inability to add oils and fats. Improves appearance and refreshes the skin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

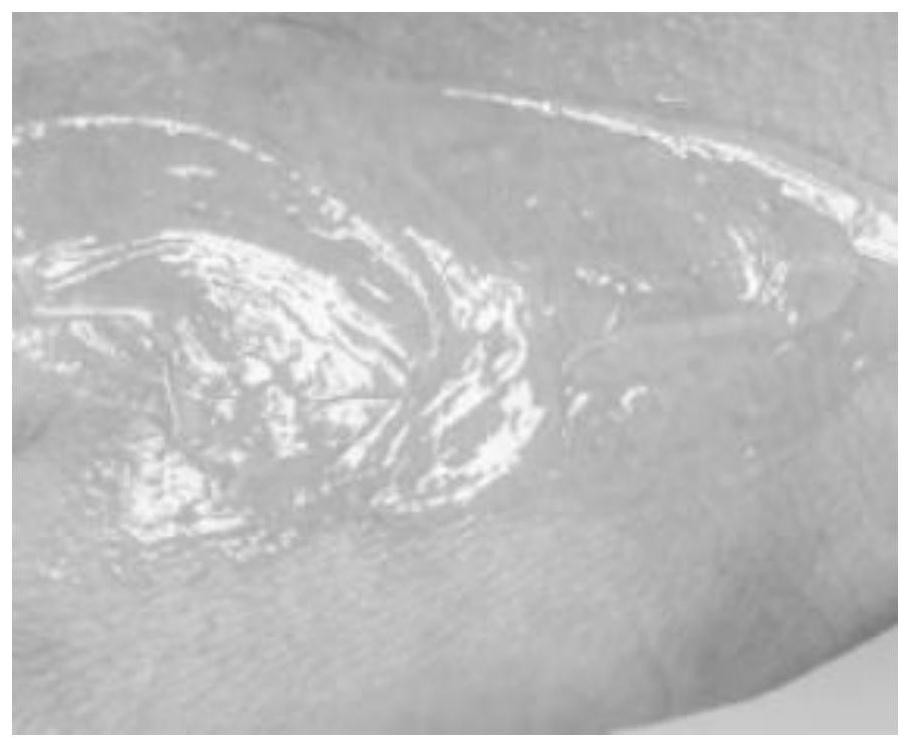

Image

Examples

Embodiment 1

[0049] The raw materials were weighed according to the mass ratio of 20 parts of XL (containing 1.5 parts of sucrose laurate, 0.6 parts of sucrose stearate), 90.9 parts of synthetic oil, 5 parts of polyglycerol-3, and 2 parts of functional additives. The D phase emulsification method was used to prepare the O / D phase gel.

Embodiment 2

[0051] The raw materials were weighed according to the mass ratio of 0.35 part of sodium subtilisin, 98.65 parts of mineral oil and 1 part of glycerol, and the O / D phase gel was prepared by the D-phase emulsification method.

Embodiment 3

[0053] According to the mass ratio of 5 parts of polyglycerol-5 oleate, 65 parts of vegetable oil, 425 parts of polyglycerol-425 and 5 parts of abrasive particles, the raw materials were weighed, and the O / D phase gel was prepared by the D-phase emulsification method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com