Round damping impact hammer with lubricating structure

A lubricating structure and impact hammer technology, which is applied in infrastructure engineering, engine lubrication, construction, etc., can solve the problems of easy tearing of the square hammer shell and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

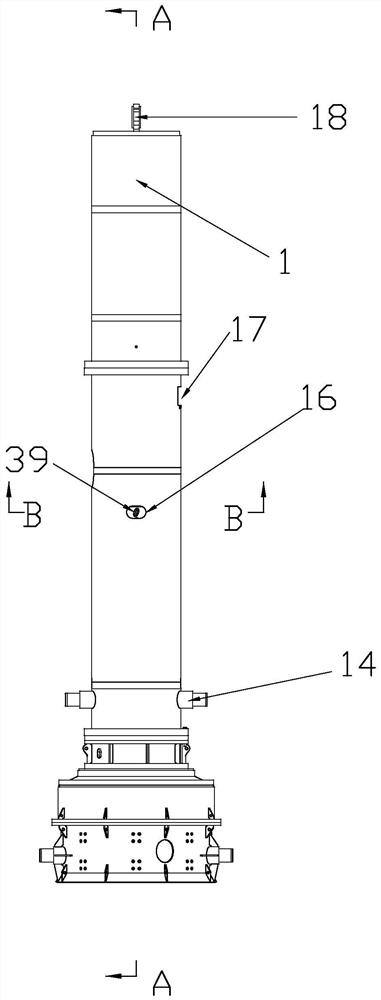

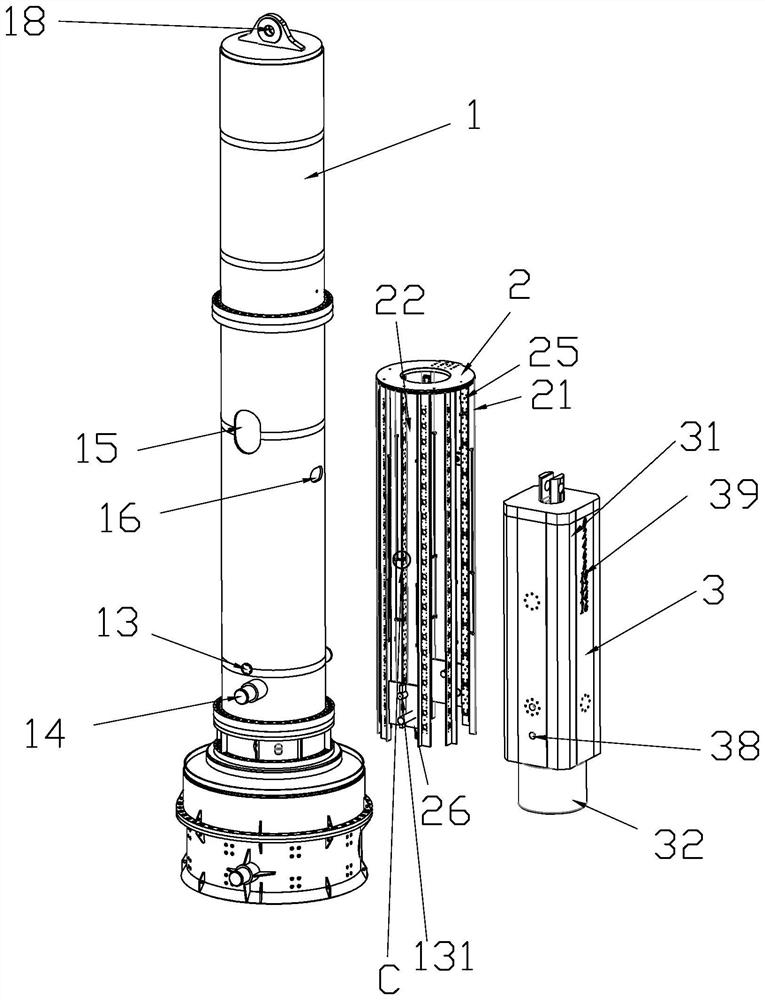

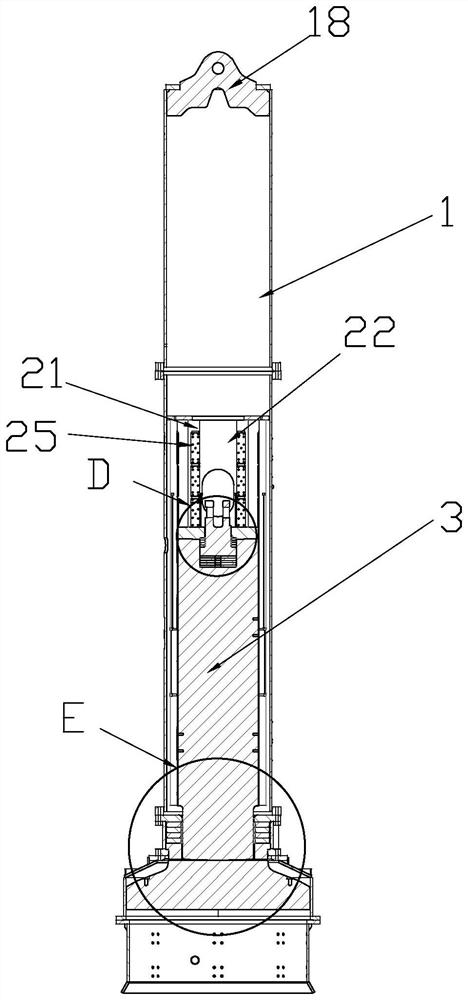

[0042] like Figure 1-Figure 8 As shown, a circular shock-absorbing impact hammer with a lubricated structure includes a hammer shell 1, a hammer frame 2 disposed inside the hammer shell 1, and a hammer core 3 disposed in the hammer frame 2. The hammer frame 2 includes eight A hammer core track 21, an impact chamber 22 for the hammer core 3 to move axially along the hammer core track 21 is formed between the hammer core tracks 21, the hammer shell 1 has a circular cross-section, and the hammer shell 1 and The impact chamber 22 cooperates to form four air passages 11 , the hammer core is square, and guide surfaces 31 are provided on both sides of each corner of the hammer core 3 , and the hammer core 3 can be positioned through the eight hammer core tracks 21 . Guide, the hammer core track 21 is provided with a lubricating oil channel 23 axially, one end of the lubricating oil channel 23 is provided with an oil supply nozzle 231, and the other end is provided with a number of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com