Groove pressing structure and template system

A technology for pressing grooves and templates, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, building construction, etc., which can solve problems such as rotten roots and large sizes of metal parts, and achieve reduction Obstruction, cost reduction, and effect of improving the quality of groove forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

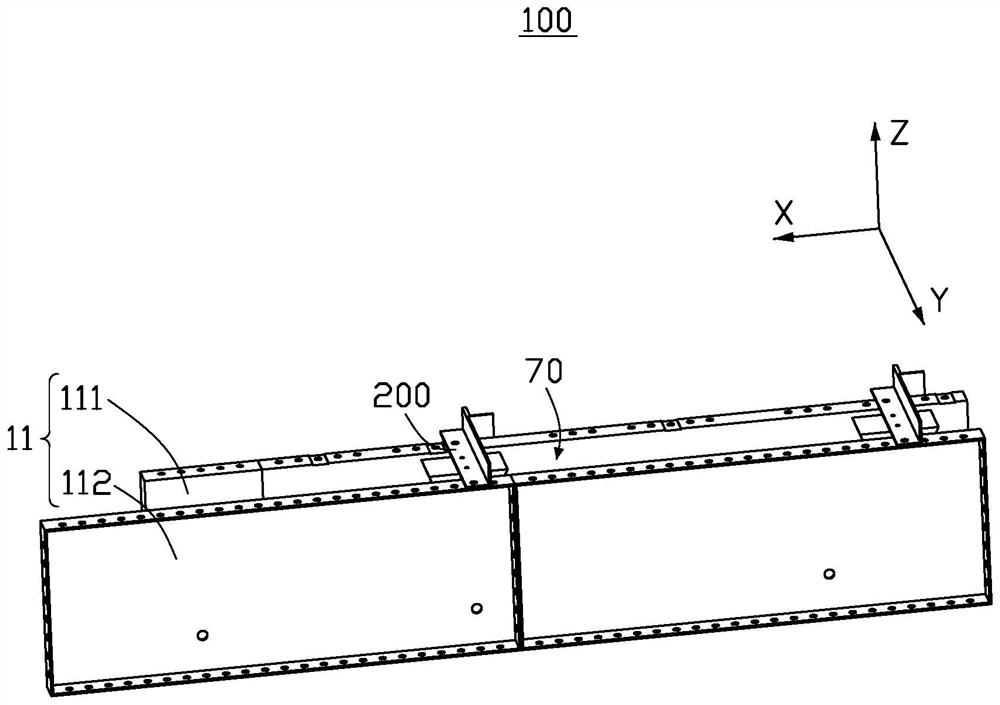

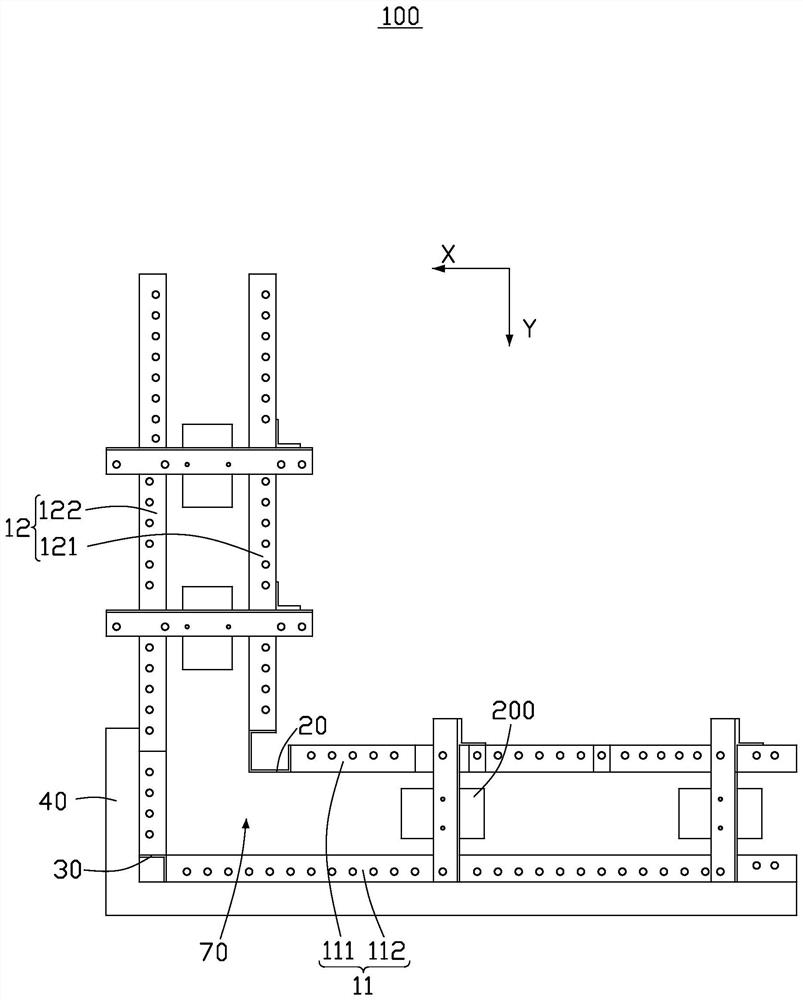

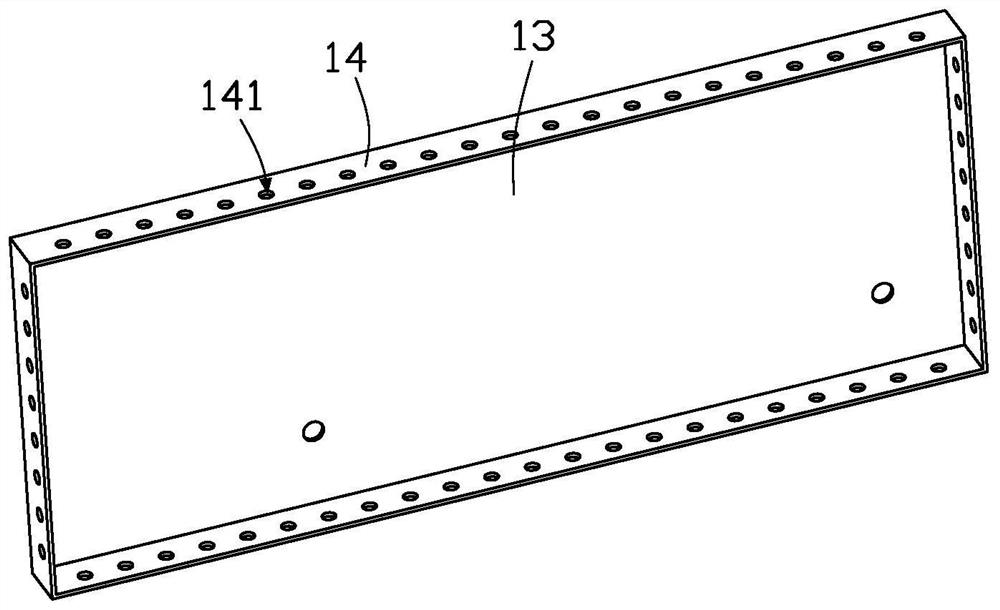

[0066] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application. Obviously, the described embodiments are only a part of the embodiments of the present application, rather than all the embodiments.

[0067] It should be noted that when a component is considered to be "connected" to another component, it can be directly connected to another component or there may be an intervening component at the same time. When a component is considered to be "set on" another component, it may be located directly on the other component or may co-exist with an intervening component. The terms "top," "bottom," "top," "bottom," "left," "right," "front," "back," and similar expressions are used herein for illustrative purposes only.

[0068] When two elements (planes, lines) are arranged in parallel, it should be understood that the relationship between the two elements includes both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com