Hydraulic valve and raw material conveying device and method for organic solid waste pyrolysis

A technology of raw material conveying and organic solid waste, applied in the direction of valve operation/release device, valve device, valve details, etc., can solve the problems of easy deformation of hydraulic valve plate, hydraulic valve blockage, etc., to ensure air tightness and high efficiency Conveying and avoiding the effect of amplifying and deforming easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

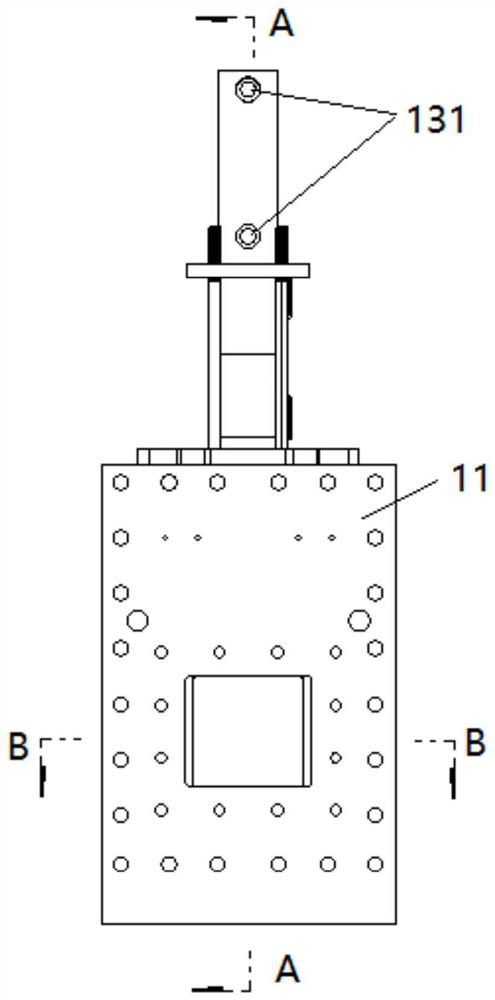

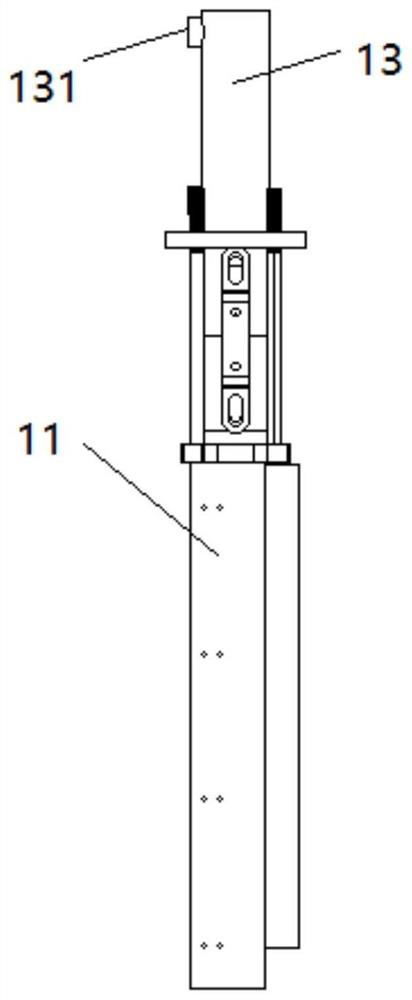

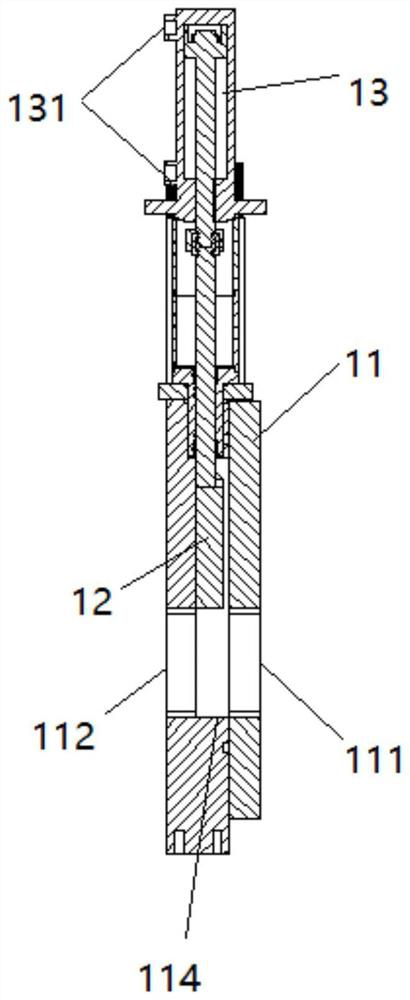

[0062] This embodiment provides a hydraulic valve, refer to Figure 1-5, the hydraulic valve includes: a valve body 11 , a valve plate 12 and a hydraulic cylinder 13 , the valve body 11 includes a feed port 111 and a discharge port 112 , and the hydraulic cylinder 13 includes an oil supply and return port 131 . image 3 for figure 1 Left side sectional view in the direction of middle A, Figure 4 for figure 1 The horizontal section in the direction B in the middle.

[0063] The discharge port 112 is larger than the feed port 111. The valve plate 12 is arranged in the valve body 11 and is located between the feed port 111 and the discharge port 112. The surface of the valve plate 12 relative to the discharge port 112 is larger than that of the valve plate 12 relative to the discharge port 112. The surface of the feed port 111.

[0064] The valve plate 12 is used to control the communication area between the inlet port 111 and the outlet port 112 under the action of hydrauli...

Embodiment 2

[0077] This embodiment provides a raw material conveying device for pyrolysis of organic solid waste. refer to Image 6 , The raw material conveying device includes: hydraulic valve 1, first hydraulic press 2, push material pipeline 3, push material piston, feed bin 5, platen valve 6, first sealed pipe 7, second sealed pipe 8 and second hydraulic press.

[0078] The hydraulic valve 1 is the hydraulic valve in the first embodiment.

[0079] The first hydraulic press 2 is fixedly connected with the first end of the pushing pipe 3 , the hydraulic rod of the first hydraulic press 2 is fixedly connected with the pushing piston, and the pushing piston is located in the pushing pipe 3 .

[0080] The second end of the push pipe 3 is communicated with the push port of the feed bin 5, the discharge port of the feed bin 5 is communicated with the first end of the first sealing pipe 7, and the second end of the first sealing pipe 7 is communicated with the hydraulic valve The feed port ...

Embodiment 3

[0112] This embodiment provides a raw material conveying method for pyrolysis of organic solid waste. The raw material conveying method is realized by using the raw material conveying device for pyrolysis of organic solid waste in Example 2.

[0113] refer to Figure 8 , the raw material conveying method includes:

[0114] S11. Control the platen valve to compress the raw materials in the feed bin.

[0115] S12, controlling the pushing piston to push the compressed raw material into the first sealing pipe.

[0116] S13. When the pressure value of the first hydraulic press reaches the pressure threshold, control the hydraulic valve to be in an open state, so that the raw material enters the second sealed pipeline from the first sealed pipeline.

[0117]Among them, the raw material continues to enter the first sealed pipeline under the push of the pushing piston, which increases the pressure value of the first hydraulic press. The pressure value of the first hydraulic press ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com