Liquid separation device for heat exchanger and heat exchanger

A heat exchanger and liquid separation technology, which is used in refrigeration and liquefaction, lighting and heating equipment, refrigerators, etc., can solve the problems of affecting heat exchange effect and uneven mixing of gas and liquid phases, preventing separation and improving heat exchange. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

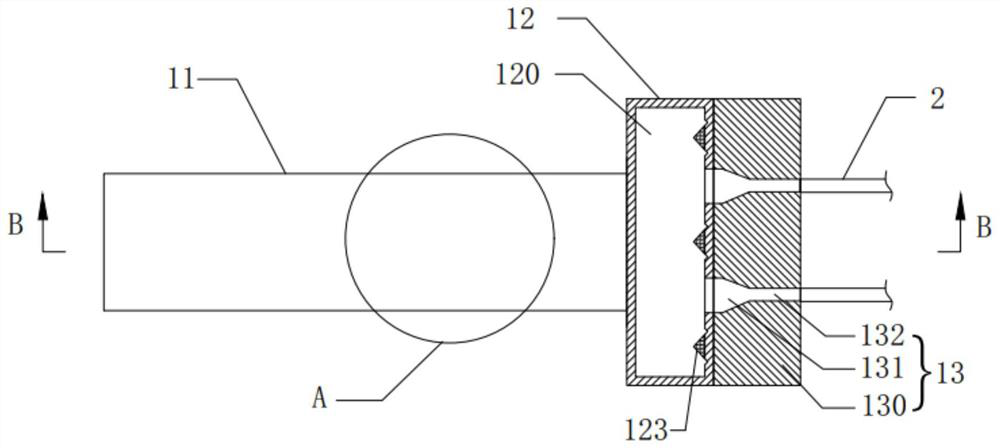

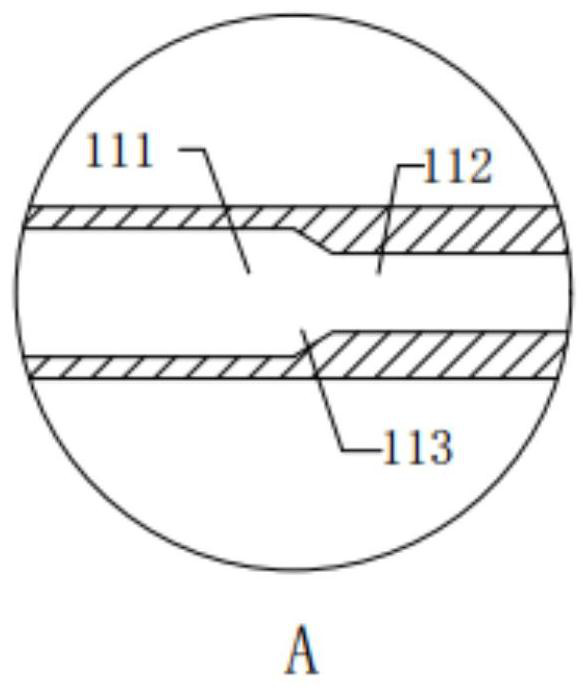

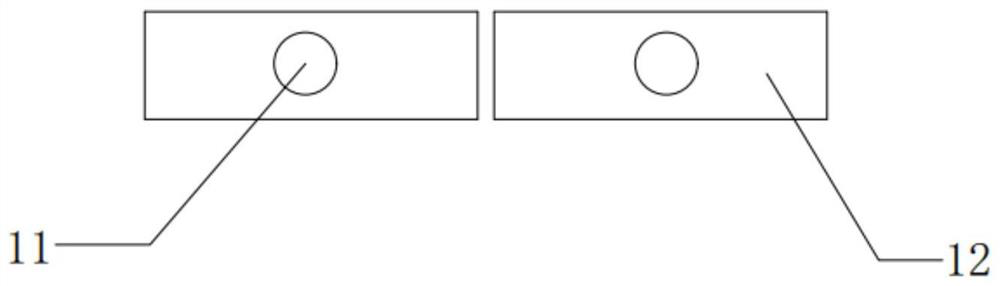

[0041] Combine below Figure 1 to Figure 3 The first embodiment of the present invention is introduced, wherein, figure 1 is a schematic structural diagram of Embodiment 1 of the liquid separation device of the present invention; figure 2 Yes figure 1 A partial enlarged view of the sectional view along the B-B line at A; image 3 Yesfigure 1 left view diagram.

[0042] like figure 1 As shown, the liquid separation device of the present invention includes a liquid inlet pipe 11, a liquid separation member 12 and a speed-increasing member 13. The liquid separation member 12 has a mixing chamber 120 in it, and the mixing chamber 120 is communicated with the liquid inlet pipe 11. The liquid-phase refrigerant entering the mixing chamber 120 is mixed with the gas-phase refrigerant, one end of the speed-increasing member 13 is communicated with the mixing chamber 120, and the other end of the speed-increasing member 13 is communicated with the heat exchange tube 2 of the heat ex...

Embodiment 2

[0089] Combine below Figure 4 to Figure 8 A second embodiment of the present invention is introduced, wherein, Figure 4 is a schematic structural diagram of Embodiment 2 of the liquid separating device of the present invention; Figure 5 Yes Figure 4 The schematic cross-sectional structure along the C-C line in the middle (the protruding structure is not shown); Image 6 Yes Figure 4 Schematic diagram of the cross-sectional structure along the D-D line in the middle; Figure 7 Yes Figure 4 A partial enlarged view of the sectional view along the F-F line at E; Figure 8 Yes Figure 4 left view diagram.

[0090] like Figure 4 As shown, the liquid separation device of the present invention includes a liquid inlet pipe 11, a liquid separation member 12 which is sequentially communicated with the liquid inlet pipe 11, and a speed-increasing member 13 communicated with the liquid separation member 12. The liquid separation member 12 includes a layered first The liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com