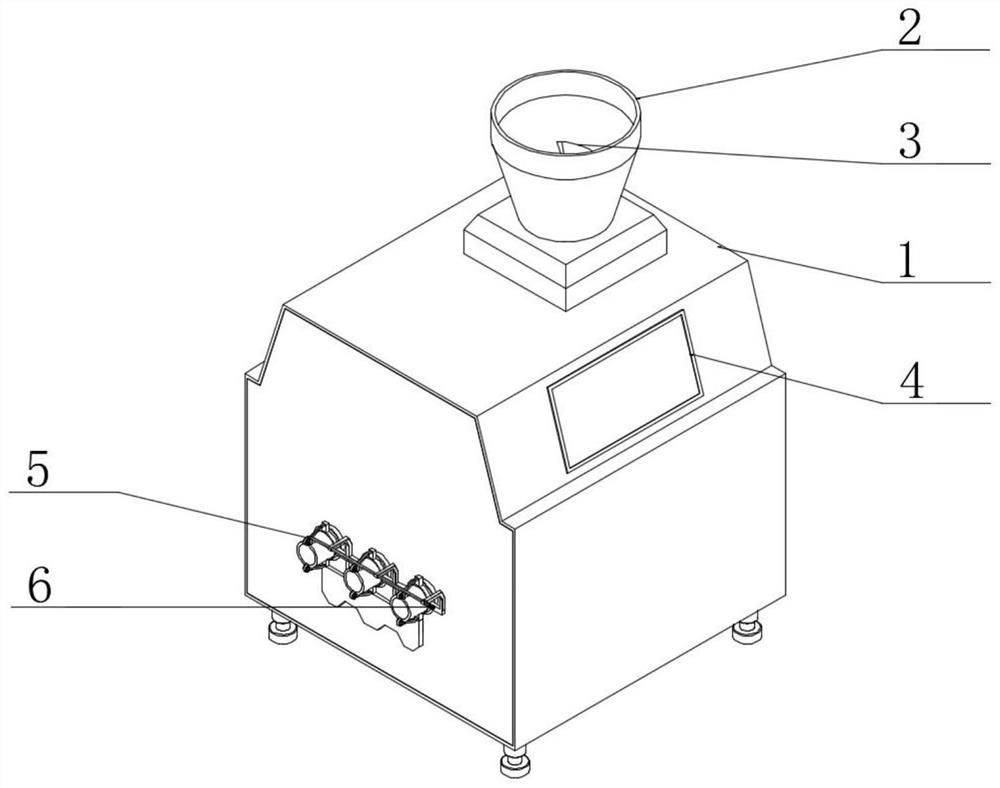

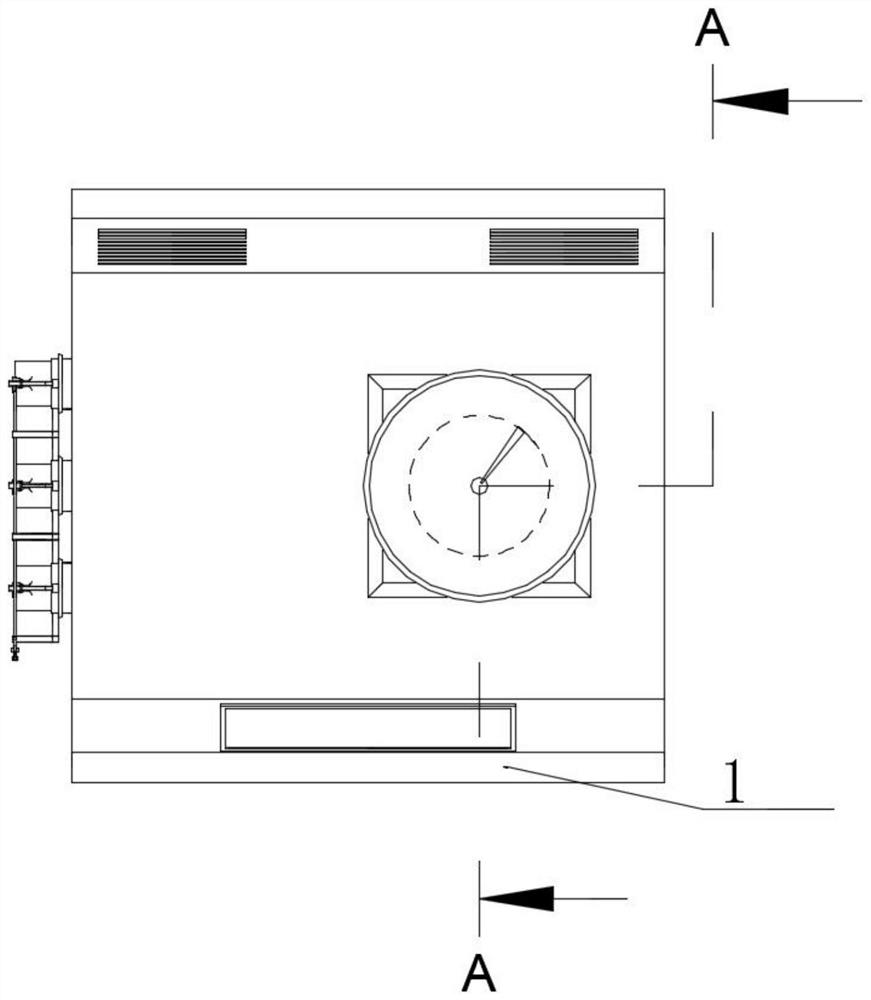

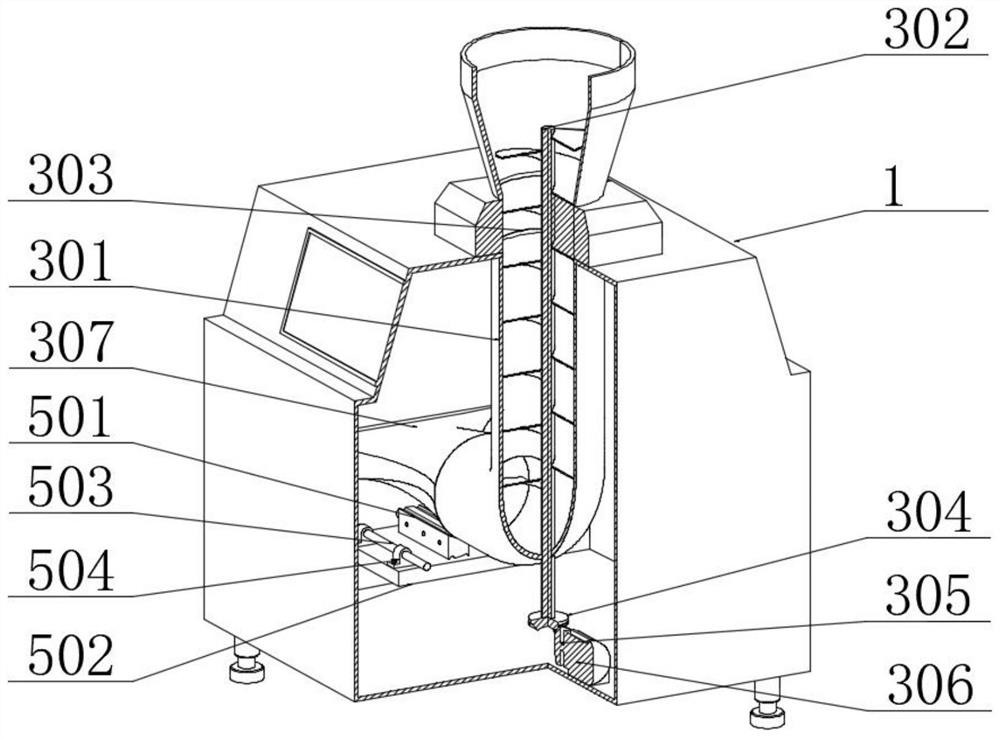

Preparation method and filling equipment of spiced sausages

A spiced sausage and filling equipment technology, which is applied in sausage stuffing machines, food science, etc., can solve problems such as the inability to adjust the feeding speed of casings, affect the quality and quality of sausages, and unfavorable thickness of sausages, etc., so as to improve filling efficiency , reduce labor intensity and avoid overfilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] The embodiment of the present invention provides a preparation method of five-spice sausage, specifically according to the following steps:

[0043] S1: Material preparation, according to the sausage recipe, prepare pork hind leg meat, pork ribs, pork skin, pig blood, white sugar, salt, five-spice powder, cooking wine, white wine, soy sauce, pepper, pepper, ginger powder;

[0044] S2: ground meat processing, put the pork hind leg meat and pork rib refined meat in the above-mentioned S1 into the meat-grinding equipment for grinding and processing, and pour the liquor and cooking wine in the above-mentioned S1 into the equipment respectively when the equipment is grinding the meat, The crushing time is 20 minutes, and after the crushing work is completed, let it stand for 15 minutes;

[0045] S3: Mix the meat ingredients, pour the minced meat after standing in the above S2 into the marinating bucket, and then put the five-spice powder, white sugar, salt, soy sauce, Chines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com