Metal cabinet and processing method thereof

A cabinet and metal technology, applied in the field of metal cabinets and their processing, can solve the problems of low structural strength, simple cabinet structure, affecting the service life of cabinets, etc., and achieves the effects of not easily falling apart, improving assembly speed, and facilitating welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

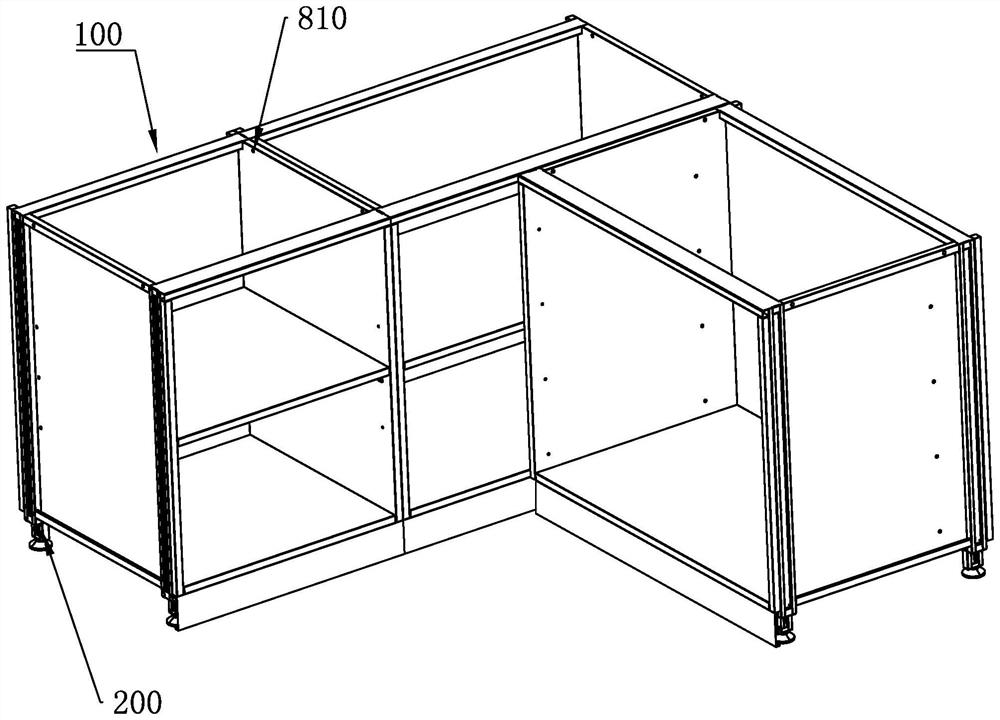

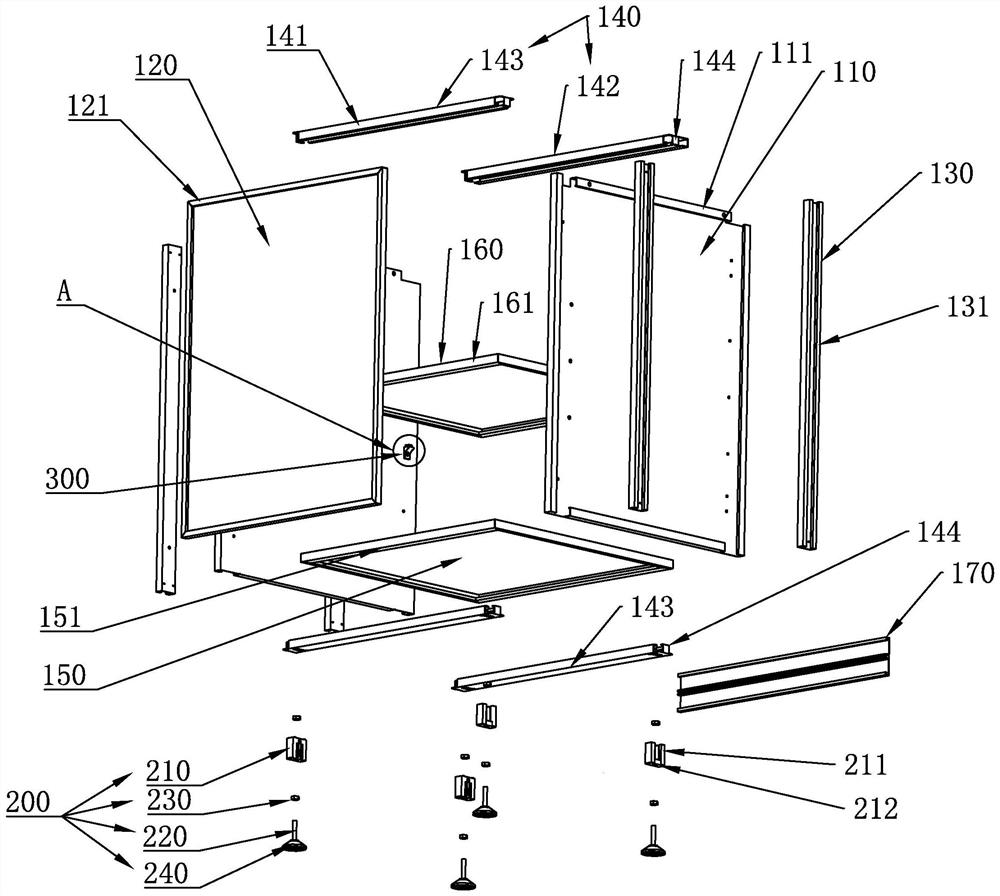

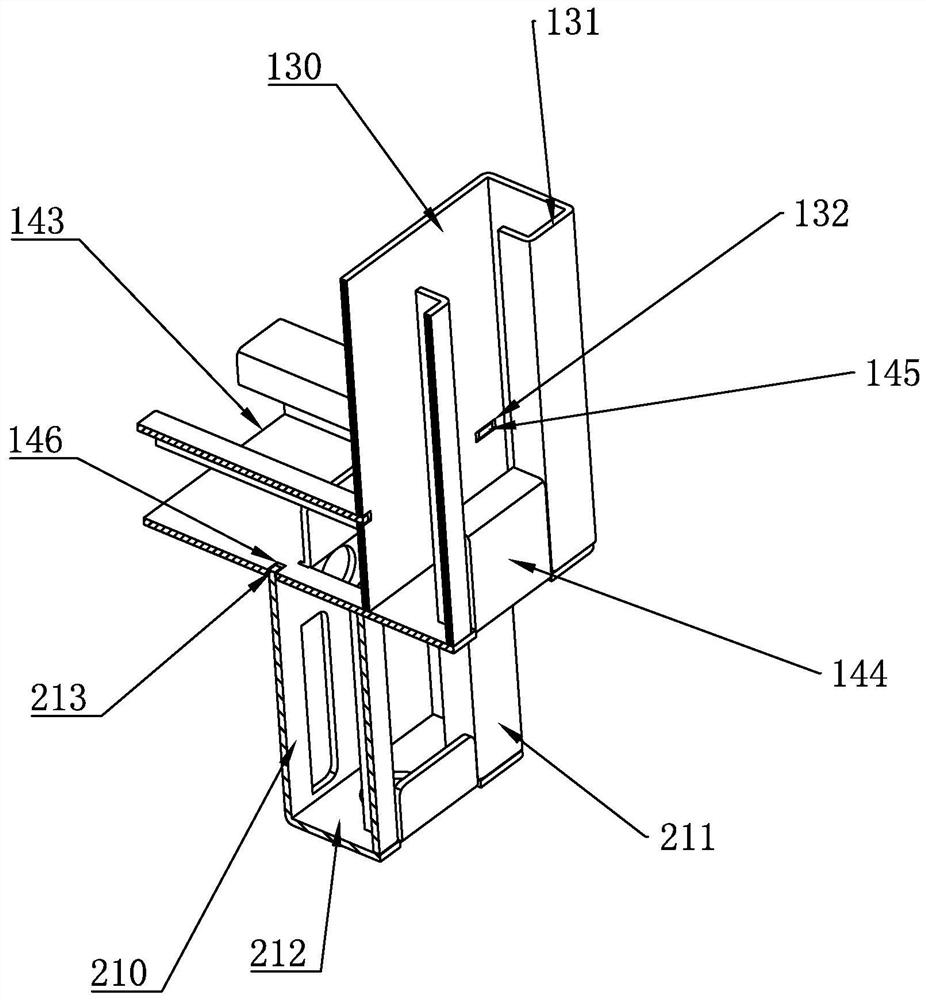

[0049] like Figure 1-Figure 4 As shown, the embodiment of the present application provides a metal cabinet, which includes a plurality of cabinet bodies 100 spliced with each other. The cabinet body 100 includes: side panels 110, which are placed on both sides of the cabinet body 100, and four sides of the side panels 110. A first bending edge 111 is provided; the back plate 120 is placed on the rear side of the cabinet body 100 , and the four sides of the back plate 120 are provided with second bending edges 121 ; , the two sides of the column 130 are provided with a third bending edge 131; the beam 140 is placed on the upper and lower ends of the column 130, and the two sides of the beam 140 are provided with a fourth bending edge 141; the bottom plate 150 is placed on The lower side of the cabinet body 100 is placed on the beam 140, and the four sides of the bottom plate 150 are provided with fifth bending edges 151; the adjusting feet 200 are placed on the lower side of...

Embodiment 2

[0058] like Figure 5-Figure 10As shown, the present application also provides a processing method for a metal cabinet, the specific steps include: S1: laser cutting blanking: selecting a plate according to the requirements of the drawing, and cutting out the blank of the side panel 110 and the blank of the back panel 120 by controlling the laser cutting device 400 , the bottom plate 150 blank, the middle plate 160 blank, the column 130 blank, the beam 140 blank, the adjustment seat 210 blank; S2: Deburring: remove the blanked side plate 110 blank, back plate 120 blank, bottom plate 150 blank, and middle plate 160 The blank, the blank of the column 130, the blank of the beam 140, the burr on the edge of the blank of the adjustment seat 210; S3: Bending: According to the drawing, the blank of the side plate 110, the blank of the back plate 120, the blank of the bottom plate 150, Bend the blank of the middle plate 160, the blank of the column 130, the blank of the beam 140, and ...

Embodiment 3

[0071] like Figure 11 , Figure 12 As shown, the embodiment of the present application also provides a metal cabinet, in addition to including the above technical features, the cabinet body 100 is provided with a reinforcing layer 600, and the reinforcing layer 600 is respectively placed on the side plate 110, the back plate 120, and the bottom plate 150. , one side of the middle plate 160, the other side of the reinforcing layer 600 is provided with an encapsulation plate 610, the reinforcing layer 600 includes a plurality of meshes 603 in the shape of regular hexagons, and the reinforcing layer 600 is provided with a first abutting portion 601 , the transverse meshes 603 are connected by a first abutting portion 601 , the reinforcing layer 600 is provided with a second abutting portion 602 , and the longitudinal meshes 603 are connected by a second abutting portion 602 .

[0072] The reinforcing layer 600 adopts an integrated structure. The reinforcing layer 600 is welded ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap