Vibration type stalk picking equipment for tea processing

A vibration-type, tea-stem technology, which is applied in tea treatment before extraction, solid separation, chemical instruments and methods, etc., can solve the problems of single function, insufficient fineness, and poor practicability of picking stems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

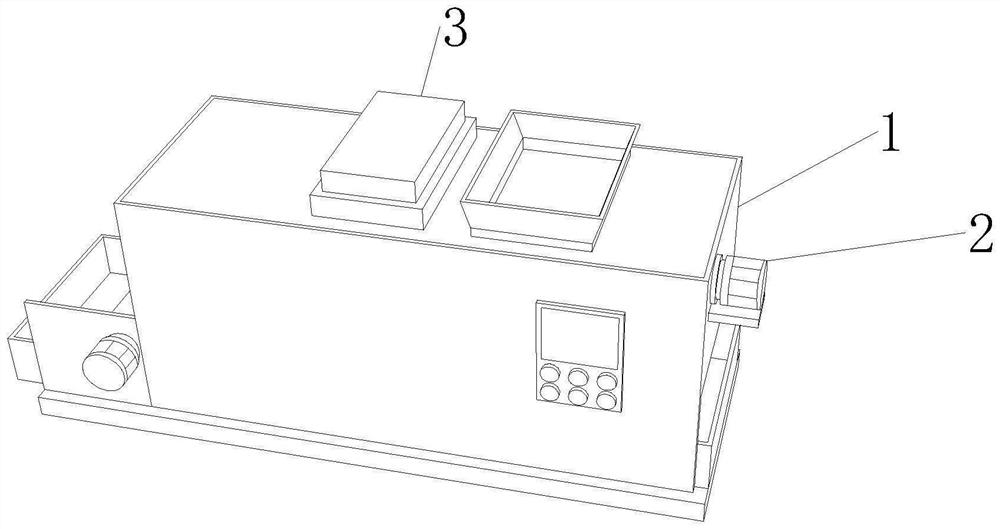

Embodiment 1

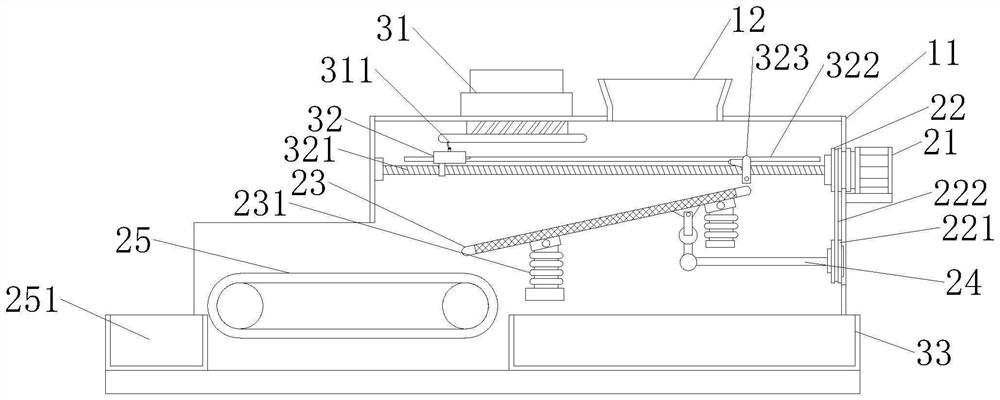

[0031] like Figure 1-6As shown, the present invention provides a vibration type stem picking device for tea processing, including a vibration type stem picking device main body 1, and the vibration type stem picking device main body 1 includes an equipment installation box 11, and the upper surface of the equipment installation box 11 is fixedly installed with The tea feeding port 12 and the inside of the equipment installation box 11 are provided with an electrostatic stalk picking device 3, and a vibration device 2 is arranged below the electrostatic stalk picking device 3. The vibration device 2 includes a motor 21, a driving pulley 22, and a vibration screen 23. And the rotating rod 24, the outer surface of the motor 21 is fixedly connected with the outer surface of the equipment installation box 11, the electrostatic stem picking device 3 includes a static electricity generating device 31 and a tea stem scraper 32, and the lower surface of the electrostatic generating dev...

Embodiment 2

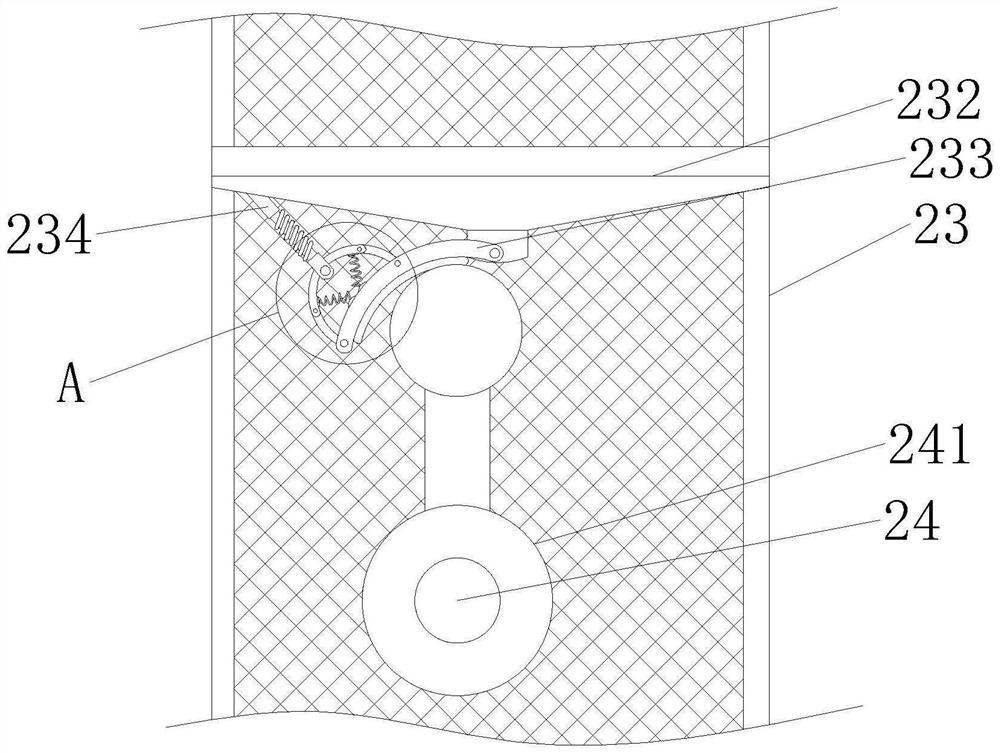

[0034] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the lower surface of the vibration screen 23 is fixedly installed with a vibration support plate 232, and the lower end of the vibration support plate 232 is hinged with an arc movable plate 233, and the arc A gasket 2331 is fixedly installed on the lower surface of the movable plate 233, an elastic connecting rod 234 is arranged above the curved movable plate 233, the upper end of the elastic connecting rod 234 is fixedly connected with the lower surface of the vibration support plate 232, and the lower end of the elastic connecting rod 234 is fixedly connected. A curved hinge rod 2341 is hinged, the lower end of the curved hinge rod 2341 is hinged with the upper surface of the arc-shaped movable plate 233, a compression spring 2342 is fixedly installed on the inner side of the curved hinge rod 2341, and the lower surface of the compression spring 2342 is connec...

Embodiment 3

[0037] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: one end of the rotating rod 24 is fixedly connected to the center of the outer surface of the driven pulley 221, and the other end of the rotating rod 24 is fixedly installed with a contact ball 241, The outer surface of the contact ball 241 is in contact with the outer surface of the gasket 2331, a conveyor 25 is provided below one side of the vibrating screen 23, a tea collecting box 251 is provided on one side of the conveyor 25, and the other side of the vibrating screen 23 A tea stem collection box 33 is provided below, an adsorption plate 311 is fixedly installed at the output end of the static electricity generating device 31, a threaded rod 321 is provided below the tea stem scraper 32, and one end of the threaded rod 321 is connected to the outer surface of the driving pulley 22. The center is fixedly connected, the other end of the threaded rod 321 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com