A method for deacidifying full-volume archives and books directly using ethylene oxide

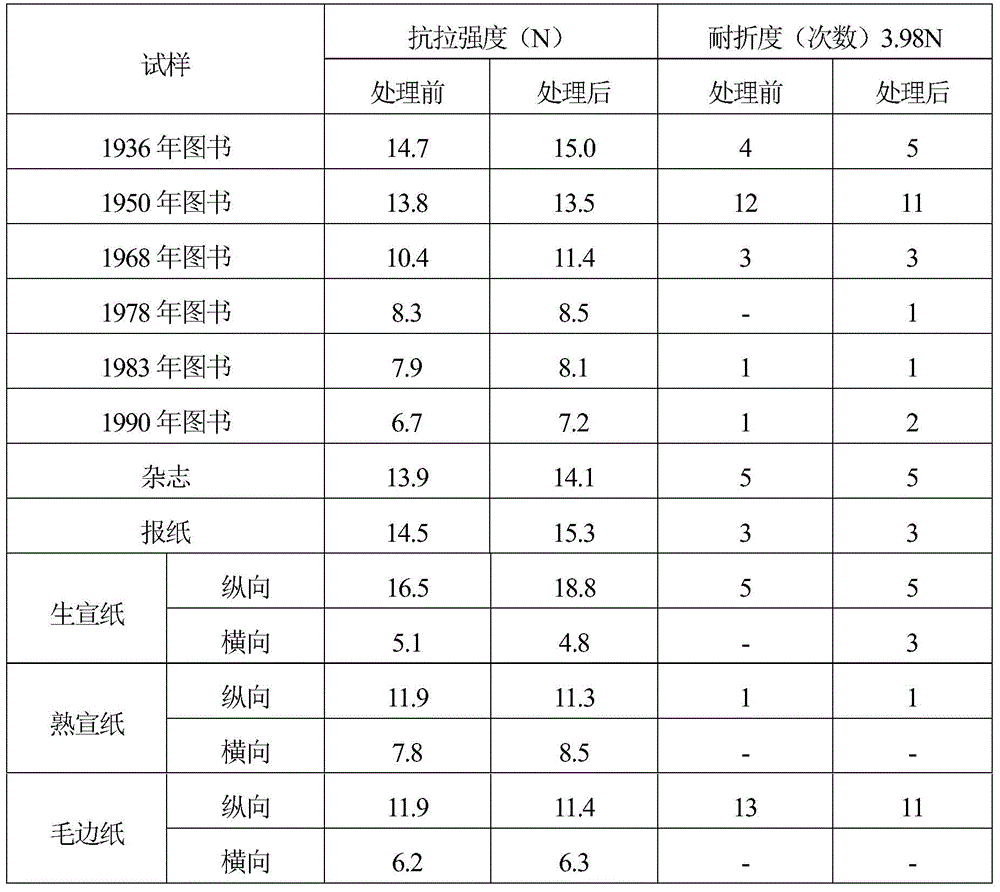

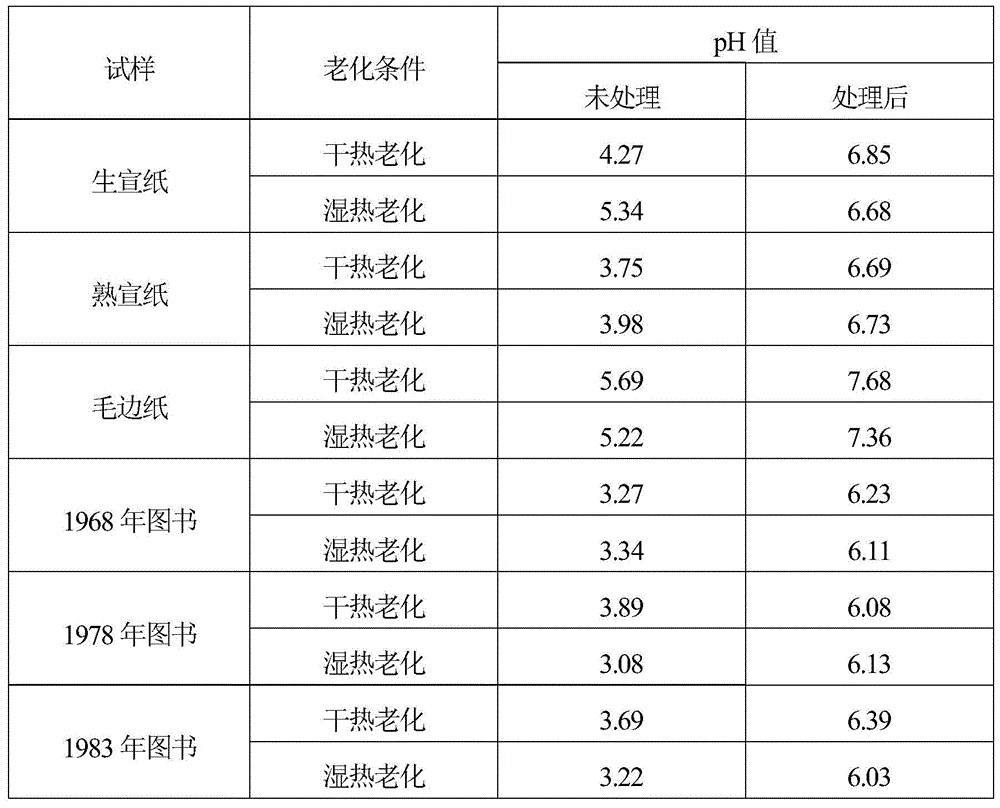

A technology of ethylene oxide and archives, which is applied in the direction of waste paper post-processing, etc., to solve the bottleneck problem, not require high vacuum degree, and increase the effect of folding endurance and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Put the whole book that needs deacidification treatment on the stainless steel frame after dedusting, and push it into a vacuum treatment box with a volume of 300 cubic decimeters. The whole book that needs deacidification treatment accounts for 70% of the volume of the vacuum treatment box. Close the chamber door, start heating after vacuuming, the temperature is controlled at 35°C, the humidity is set to 50%, and the vacuuming device is turned on so that the vacuum degree in the vacuum treatment box reaches 7mm Hg (atmospheric pressure is 726mm Hg), and stand for 20 Minutes, after the pressure no longer changes, then add 1.0g of liquid ethylene oxide per cubic decimeter according to the volume of the vacuum sealing device, that is, add 300g of liquid ethylene oxide, and the liquid ethylene oxide will quickly vaporize into ethylene oxide Alkanes gas, 35 ℃ deacidification treatment for 10 hours, pump out the ethylene oxide in the vacuum treatment box and carry out ultrav...

Embodiment 2

[0021] Put the whole book that needs deacidification treatment on the stainless steel frame after dedusting, and push it into a vacuum treatment box with a volume of 300 cubic decimeters. The whole book that needs deacidification treatment accounts for 70% of the volume of the vacuum treatment box. Close the chamber door, start heating after vacuuming, the temperature is controlled at 20°C, the humidity is set to 30%, and the vacuuming device is turned on so that the vacuum degree in the vacuum processing box reaches 7mm Hg (atmospheric pressure is 726mm Hg), and it is left to stand for 30 Minutes, after the pressure no longer changes, then add 1.5g of liquid ethylene oxide per cubic decimeter according to the volume of the vacuum sealing device, that is, add 450g of liquid ethylene oxide, and the liquid ethylene oxide will quickly vaporize into ethylene oxide Alkanes gas, 20 ℃ deacidification treatment for 20 hours, pump out the ethylene oxide in the vacuum treatment box and c...

Embodiment 3

[0023] Put the whole volume of archives that needs deacidification treatment on the stainless steel frame after dedusting, and push it into a vacuum treatment box with a volume of 300 cubic decimeters. The whole volume of archives that needs deacidification treatment accounts for 80% of the volume of the vacuum treatment box. Close the chamber door, start heating after vacuuming, the temperature is controlled at 55°C, the humidity is set at 60%, and the vacuuming device is turned on so that the vacuum degree in the vacuum processing box reaches 7mm Hg (atmospheric pressure is 726mm Hg), and it is left to stand for 10 Minutes, after the pressure no longer changes, then add 0.8g of liquid ethylene oxide per cubic decimeter according to the volume of the vacuum sealing device, that is, add 240g of liquid ethylene oxide, and the liquid ethylene oxide will quickly vaporize into ethylene oxide Alkanes gas, deacidification treatment at 55°C for 5 hours, pump out the ethylene oxide in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com