Rubber part recycling treatment device

A treatment device and reuse technology, applied in cleaning methods and appliances, chemical instruments and methods, metal processing, etc., can solve the problems of inconvenient handling, uniform crushing, and low efficiency, and achieve improved cleaning efficiency and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

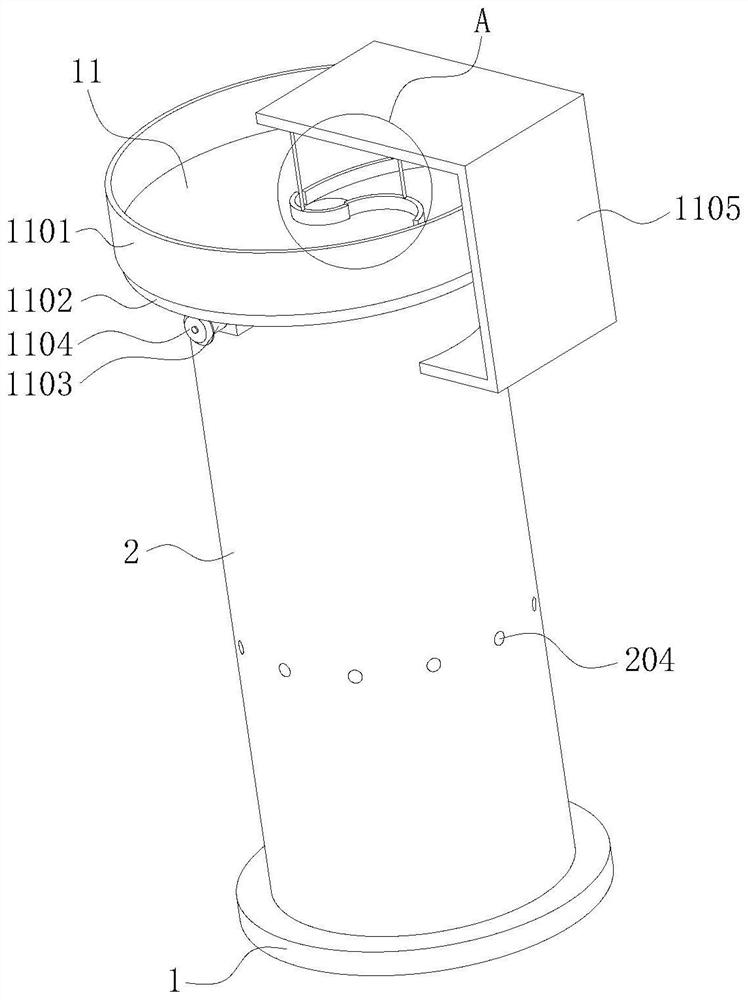

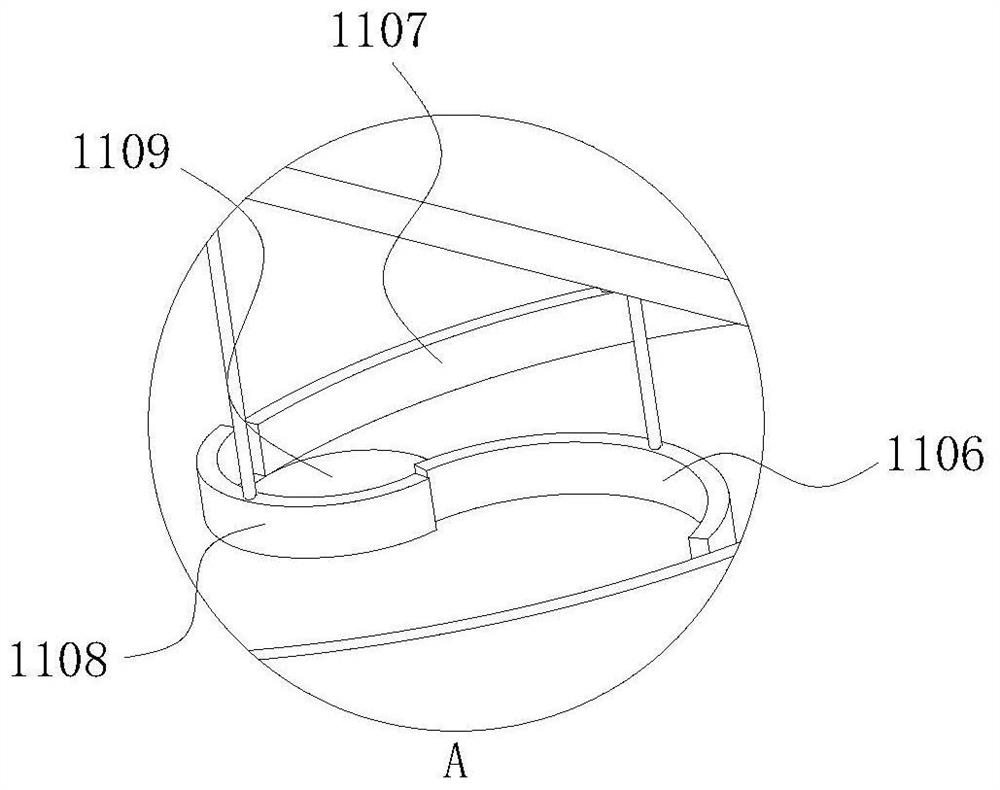

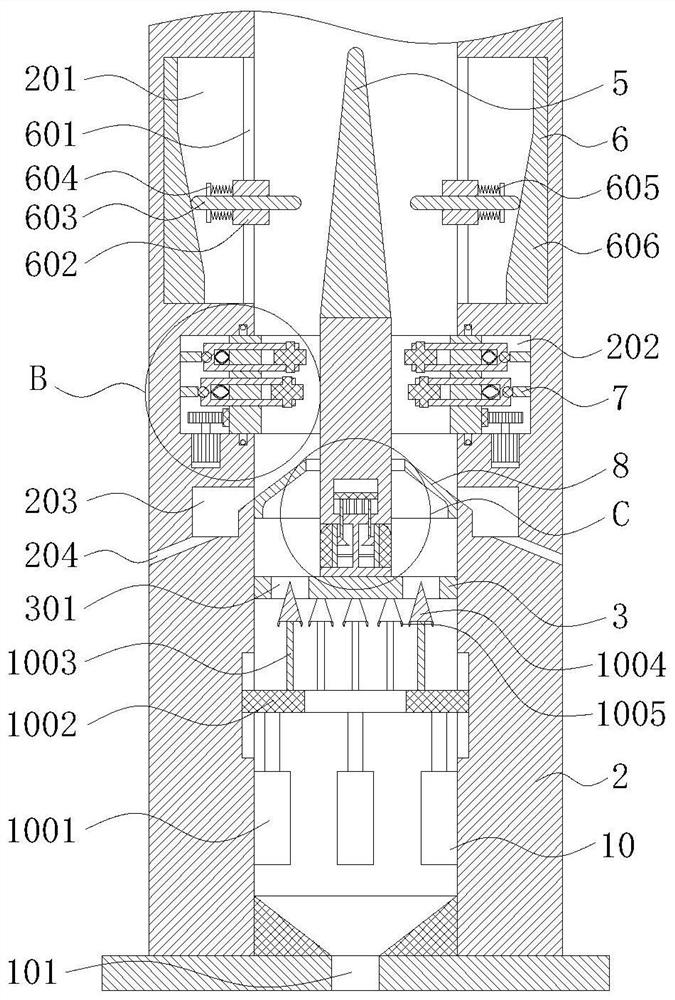

[0028] like figure 1 and image 3 As shown in the figure, this embodiment provides a device for recycling and reusing rubber parts, which includes a horizontal bottom plate 1, and a discharge port 101 is opened on the bottom plate 1; a cylindrical mounting cylinder 2 is vertically fixed on the bottom plate 1; A horizontal sieve plate 3 is fixedly installed on the inner wall of the cylinder 2, a cylindrical vertical column 4 is fixedly installed in the middle of the upper surface of the sieve plate 3, and a number of sieve holes 301 are evenly opened around the vertical column 4 on the sieve plate 3. A tapered column 5 is vertically and fixedly installed on the top of the straight column 4 .

[0029] like figure 1 , figure 2 and Figure 8As shown, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com