Cold-resistant high-toughness co-polypropylene plastic and preparation method thereof

A copolymerized polypropylene and high-toughness technology is applied in the field of cold-resistant and high-toughness copolymerized polypropylene plastics and its preparation. , Improve the effect of toughening and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

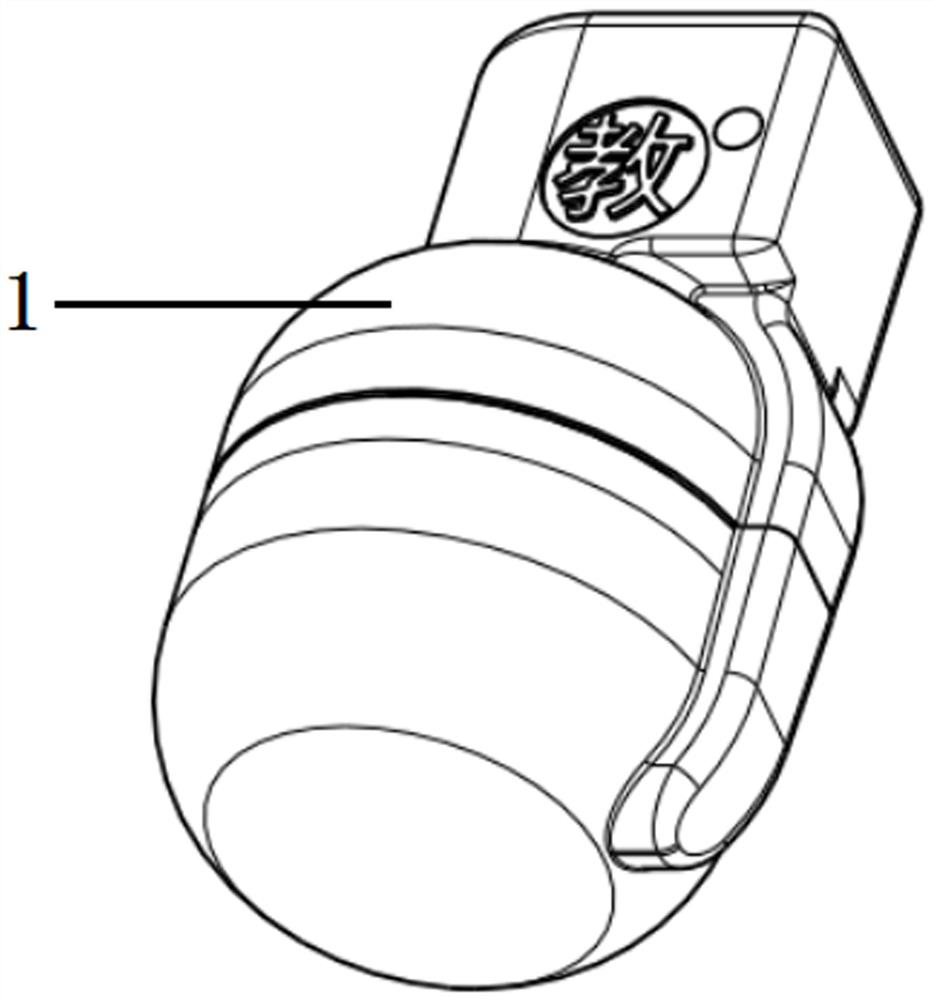

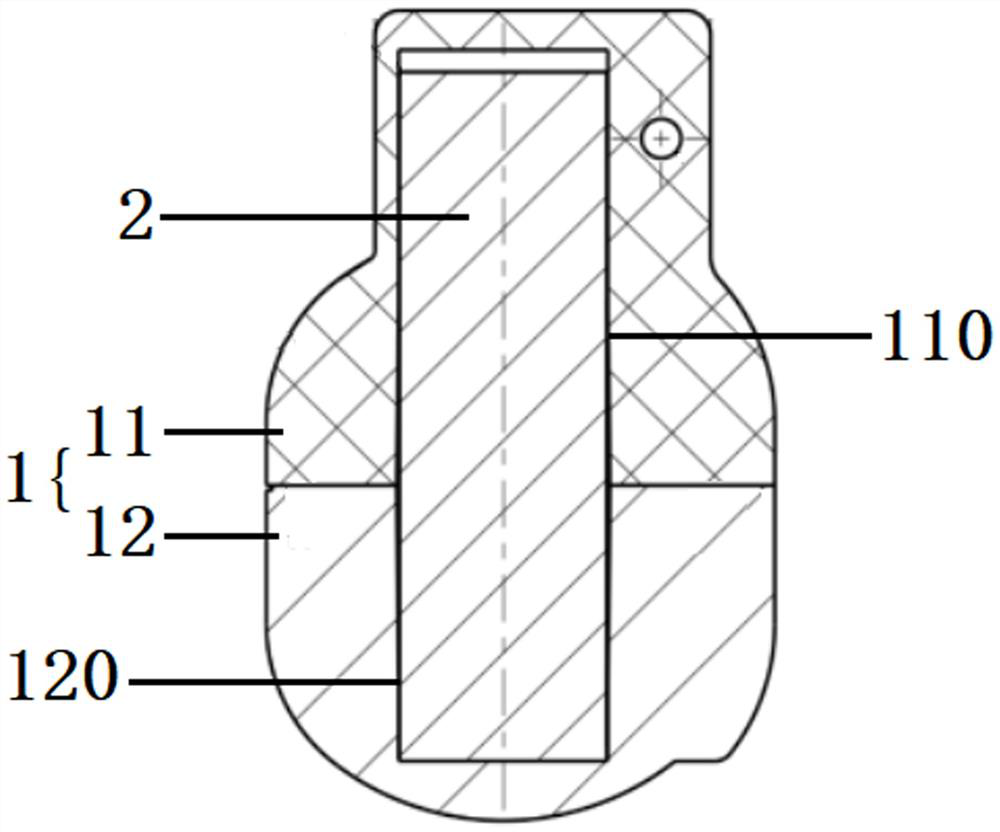

Image

Examples

Embodiment 1

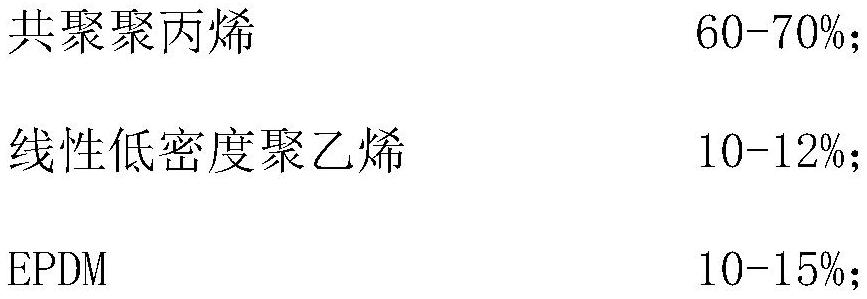

[0029] The preparation raw material of the cold-resistant and high-toughness copolymerized polypropylene plastic consists of the following components:

[0030]

[0031] The preparation method of cold-resistant and high-toughness copolymerized polypropylene plastic includes the following steps and is performed in sequence,

[0032] Step S1, using a mixer to mix copolymerized polypropylene, linear low density polyethylene, EPDM, SEBS, sorbitol, and magnesium oxide activator to obtain a raw material mixture;

[0033] In step S2, the raw material mixture is kneaded and extruded by a twin-screw mixing extruder to obtain plastic wire drawing: the temperature of the twin-screw mixing extruder from the feeding port to the discharging port is as follows: the temperature in the first zone is 330°C, and the temperature in the second zone is 330°C. The zone temperature is 330°C, and the three zone temperature is 330°C.

[0034] Step S3, cooling the plastic wire drawing by water coolin...

Embodiment 2

[0053] The preparation raw material of the cold-resistant and high-toughness copolymerized polypropylene plastic consists of the following components:

[0054]

[0055]The preparation method of cold-resistant and high-toughness copolymerized polypropylene plastic includes the following steps and is performed in sequence,

[0056] Step S1, using a mixer to mix copolymerized polypropylene, linear low density polyethylene, EPDM, SEBS, sorbitol, and magnesium oxide activator to obtain a raw material mixture;

[0057] In step S2, the raw material mixture is kneaded and extruded by a twin-screw mixing extruder to obtain plastic wire drawing: the temperature of the twin-screw mixing extruder from the feeding port to the discharging port is as follows: the temperature in the first zone is 330°C, and the temperature in the second zone is 330°C. The zone temperature is 330°C, and the three zone temperature is 330°C.

[0058] Step S3, cooling the plastic wire drawing by water cooling...

Embodiment 3

[0074] The preparation raw material of the cold-resistant and high-toughness copolymerized polypropylene plastic consists of the following components:

[0075]

[0076] The preparation method of cold-resistant and high-toughness copolymerized polypropylene plastic includes the following steps and is performed in sequence,

[0077] Step S1, using a mixer to mix copolymerized polypropylene, linear low density polyethylene, EPDM, SEBS, sorbitol, and magnesium oxide activator to obtain a raw material mixture;

[0078] In step S2, the raw material mixture is kneaded and extruded by a twin-screw mixing extruder to obtain plastic wire drawing: the temperature of the twin-screw mixing extruder from the feeding port to the discharging port is as follows: the temperature in the first zone is 330°C, and the temperature in the second zone is 330°C. The zone temperature is 330°C, and the three zone temperature is 330°C.

[0079] Step S3, cooling the plastic wire drawing by water coolin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap