Matte dry and comfortable high-elastic TPE tension sheet material and preparation method thereof

A sheet material and high-elasticity technology, which is applied in the field of matte, dry and high-elasticity TPE tensile sheet material and its preparation, can solve the problems of strong pollution of processing environment, poor hand feeling and poor elasticity of TPE tensile sheet, and achieve tensile permanent deformation Good performance, simplified production process, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

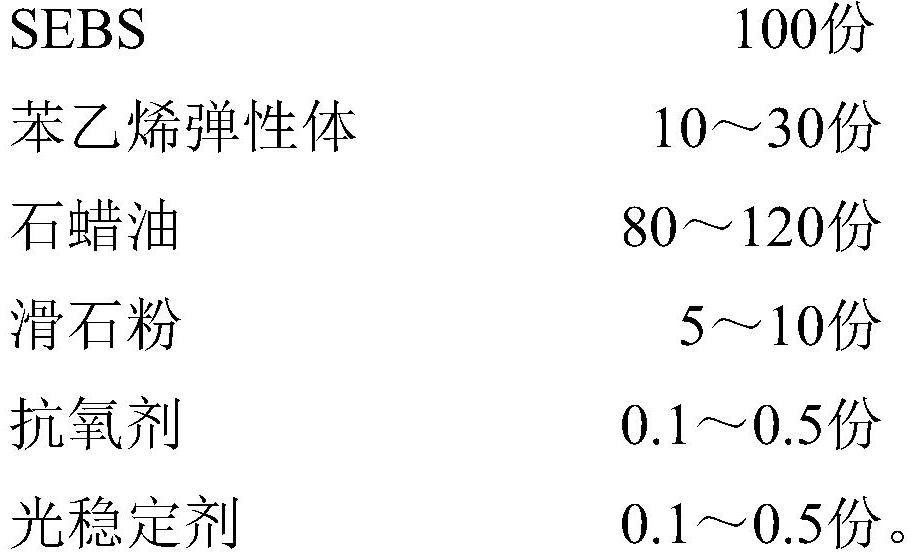

Method used

Image

Examples

Embodiment 1

[0027] raw material parts by mass SEBS 100 copies Styrene elastomer 25 servings Paraffin oil 100 copies talcum powder 5 servings Antioxidant 168 0.3 servings Antioxidant 1010 0.2 servings Light Stabilizer 770 0.3 servings

[0028] According to the above-mentioned raw material ratio, the preparation of TPE tensile sheet material is carried out, and the specific steps are as follows:

[0029] (1) Mix SEBS with paraffin oil to fully absorb oil;

[0030] (2) extruding and granulating the material obtained in step (1), styrene elastomer, talc, antioxidant and light stabilizer through a twin-screw extrusion granulator at 170-220 °C;

[0031] (3) extruding the material obtained in step (2) through a single-screw extruder at 150-190°C, and controllably producing fine and uniform melt fracture during the extrusion process, cooling to obtain a matte, dry, high-elasticity TPE tensile sheet material.

[0032] Wherein, the s...

Embodiment 2

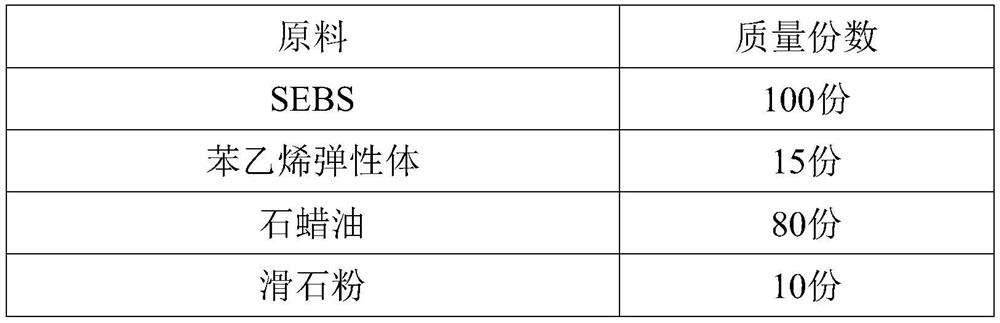

[0034]

[0035]

[0036] According to the above-mentioned raw material ratio, the preparation of TPE tensile sheet material is carried out, and the specific steps are as follows:

[0037] (1) Mix SEBS with paraffin oil to fully absorb oil;

[0038] (2) extruding and granulating the material obtained in step (1), styrene elastomer, talc, antioxidant and light stabilizer through a twin-screw extruder granulator at 170-220 °C;

[0039] (3) extruding the material obtained in step (2) through a single-screw extruder at 150-190°C, and controllably producing fine and uniform melt fracture during the extrusion process, cooling to obtain a matte, dry, high-elasticity TPE tensile sheet material.

[0040] Among them, the styrene elastomer is styrene-allyl (diisopropylamino) dimethylsilane copolymer, and the content of allyl (diisopropylamino) dimethylsilane in the copolymer is 18 weight%.

Embodiment 3

[0042] raw material parts by mass SEBS 100 copies Styrene elastomer 20 servings Paraffin oil 80 servings talcum powder 8 servings Antioxidant 168 0.2 servings Antioxidant 1010 0.2 servings Light Stabilizer 770 0.3 servings

[0043] According to the above-mentioned raw material ratio, the preparation of TPE tensile sheet material is carried out, and the specific steps are as follows:

[0044] (1) Mix SEBS with paraffin oil to fully absorb oil;

[0045] (2) extruding and granulating the material obtained in step (1), styrene elastomer, talc, antioxidant and light stabilizer through a twin-screw extruder granulator at 170-220 °C;

[0046] (3) extruding the material obtained in step (2) through a single-screw extruder at 150-190°C, and controllably producing fine and uniform melt fracture during the extrusion process, cooling to obtain a matte, dry, high-elasticity TPE tensile sheet material.

[0047] Among them, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com