Decarburization smelting method of RH vacuum furnace

A smelting method and technology of vacuum furnace, applied in the field of iron and steel metallurgy manufacturing, can solve problems such as increase in production cost, and achieve the effects of reducing the temperature of molten steel, reducing time, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

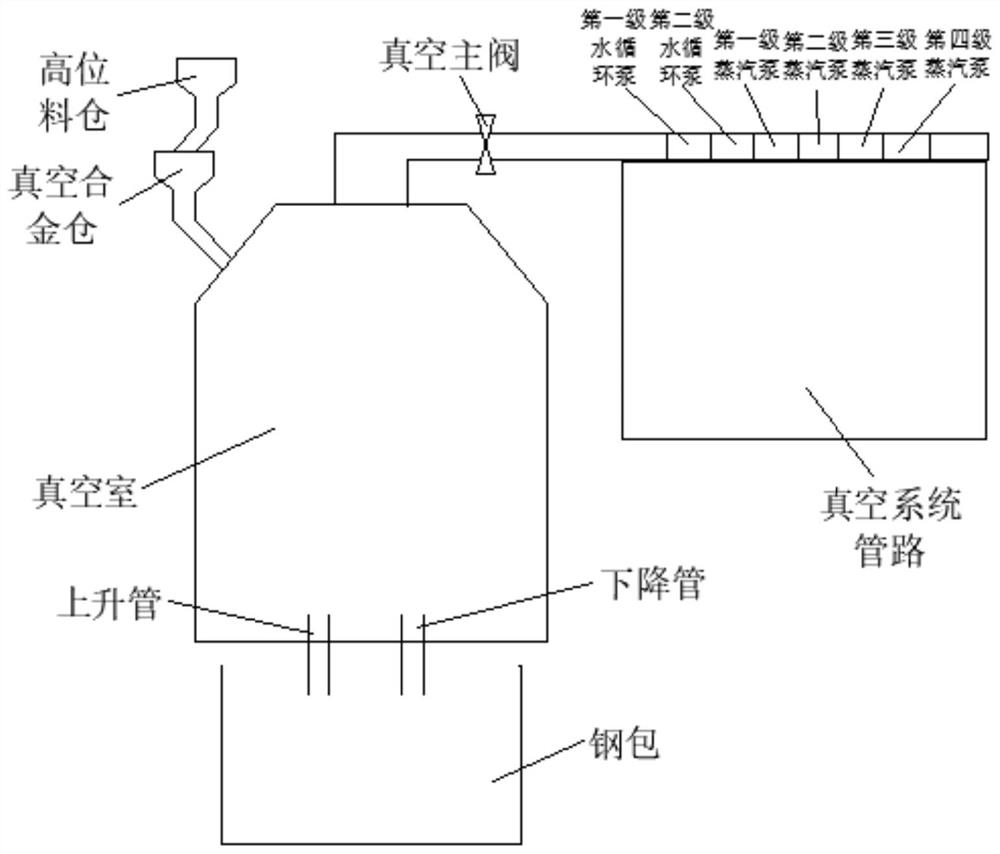

Image

Examples

Embodiment 1

[0042] S1: Before vacuuming, close the connection pipeline between the vacuum chamber and the vacuum alloy warehouse, weigh the alloy to be added during deoxidization and alloying of the steel to be smelted, and add it to the vacuum alloy warehouse from the high-level silo; open the main vacuum valve to keep away The ventilation valve between the vacuum system pipelines on one side of the vacuum chamber; after the completion of the RH ladle, close the vacuum main valve of the RH vacuum furnace to cut off the communication between the vacuum chamber and the vacuum system pipelines.

[0043] S2: Turn on the first-stage water circulation pump and start vacuuming. The working current of the first-stage water circulation pump is set to 300A, and the pumping rate is maintained at 15mbar / s. When the working current of the first-stage water circulation pump is set, the ladle containing molten steel begins to rise, and the ladle The rising speed is kept at 6m / min; when the ladle rises t...

Embodiment 2

[0047] S1: Before vacuuming, close the connection pipeline between the vacuum chamber and the vacuum alloy warehouse, weigh the alloy to be added during deoxidization and alloying of the steel to be smelted, and add it to the vacuum alloy warehouse from the high-level silo; open the main vacuum valve to keep away The ventilation valve between the vacuum system pipelines on one side of the vacuum chamber; after the completion of the RH ladle, close the vacuum main valve of the RH vacuum furnace to cut off the communication between the vacuum chamber and the vacuum system pipelines.

[0048] S2: Turn on the first-stage water circulation pump and start vacuuming. The working current of the first-stage water circulation pump is set to 350A, and the pumping rate is maintained at 30mbar / s. When the working current of the first-stage water circulation pump is set, the ladle containing molten steel begins to rise, and the ladle The ascending speed is kept at 10m / min; when the ladle ris...

Embodiment 3

[0052] S1: Before vacuuming, close the connection pipeline between the vacuum chamber and the vacuum alloy warehouse, weigh the alloy to be added during deoxidization and alloying of the steel to be smelted, and add it to the vacuum alloy warehouse from the high-level silo; open the main vacuum valve to keep away The ventilation valve between the vacuum system pipelines on one side of the vacuum chamber; after the completion of the RH ladle, close the vacuum main valve of the RH vacuum furnace to cut off the communication between the vacuum chamber and the vacuum system pipelines.

[0053] S2: Turn on the first-stage water circulation pump and start vacuuming. The working current of the first-stage water circulation pump is set to 320A, and the pumping rate is maintained at 24mbar / s. When the working current of the first-stage water circulation pump is set, the ladle containing molten steel begins to rise, and the ladle The ascending speed is kept at 8m / min; when the ladle rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com