Moisture-proof fabric

A fabric and waterproof membrane technology, applied in the textile field, can solve problems such as affecting physical fitness, breeding bacteria, and damp bed equipment, and achieves the effect of increasing the applicable experience, preventing the growth of bacteria, and improving the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

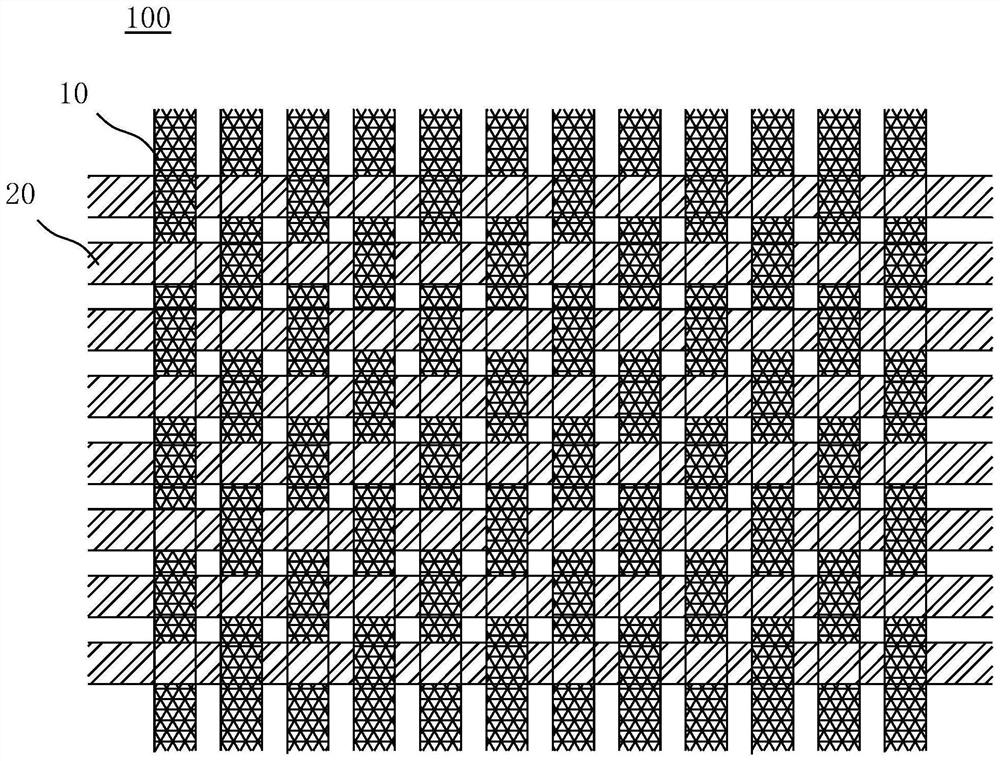

[0034] like Figure 1 to Figure 4 As shown, the first embodiment of the present disclosure provides a moisture-proof fabric 100, including a first polyester blended chemical fiber fabric 10 and a second polyester 20, and the first polyester blended chemical fiber fabric 10 and the second polyester 20 are woven. Among them, the first polyester blended chemical fiber fabric 10 is obtained by the first polyester through the existing blending process, and the blending process is a textile product woven by the first polyester and other natural fibers such as cotton wool, silk, linen, etc., and has the style of polyester. And the advantages of cotton fabrics. In the moisture-proof fabric 100 provided by the first embodiment of the present disclosure, the first polyester is moisture-conducting polyester, and the second polyester 20 is suction-discharging polyester 21 .

[0035] Moisture-conducting polyester is an existing moisture-absorbing and moisture-conducting chemical fiber. It...

Embodiment 11

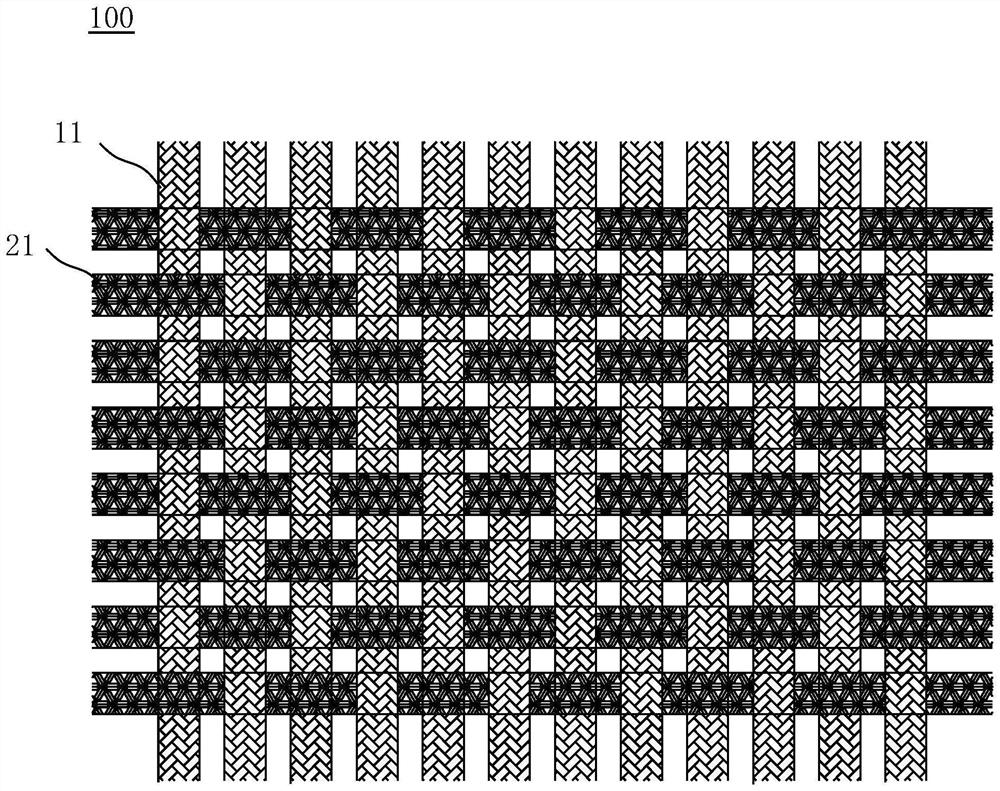

[0038] The first embodiment of the present disclosure provides a moisture-proof fabric 101, comprising: 30 parts by weight of a moisture-conducting polypropylene blended chemical fiber fabric 11 and 70 parts by weight of a suction-discharge polyester 21, the moisture-conducting polypropylene blended chemical fiber fabric 11 and the suction-discharge polyester 21 are woven together. During weaving, the existing plane mechanism process weaving method can be used for weaving. Therefore, in the moisture-proof fabric 101 provided by the first embodiment of the present disclosure, one side of the moisture-conducting polypropylene blended chemical fiber fabric 11 can be used as the close-fitting surface, and the absorbing and draining polyester 21 can be used as the body surface. One side is used as the bottom, and this is an example to illustrate. When the body surface of the moisture-proof fabric 101 provided in the first embodiment of the present disclosure is damp or perspired, th...

Embodiment 12

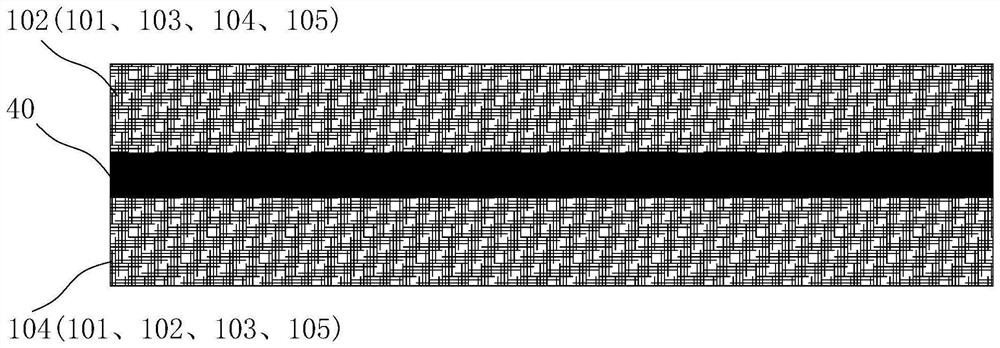

[0040] The first embodiment of the present disclosure provides a moisture-proof fabric 102, comprising: 40 parts by weight of a moisture-conducting polypropylene blended chemical fiber fabric 11 and 60 parts by weight of a suction-discharge polyester 21, the moisture-conducting polypropylene blended chemical fiber fabric 11 and the suction-discharge polyester 21 are woven together, During weaving, the existing plane mechanism process weaving method can be used for weaving to obtain the moisture-proof fabric 102 provided by the first embodiment of the present disclosure, so as to realize the functions of breathability and moisture-proof.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap