Bidirectional wave plasma thruster for spacecraft

A plasma and thruster technology, applied in the direction of using plasma, plasma, thrust reverser, etc., can solve the problems of increasing the specific thrust and specific impulse of the thruster, so as to eliminate parasitic discharge, eliminate power loss, reduce weight and effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Two-way wave plasma thrusters for spacecraft are mainly used in spaceborne satellites including small satellites to realize their transfer from parking orbit to target orbit, orbit maintenance, attitude control, altitude control, unloading attitude control system, orbit maneuvers and derailments.

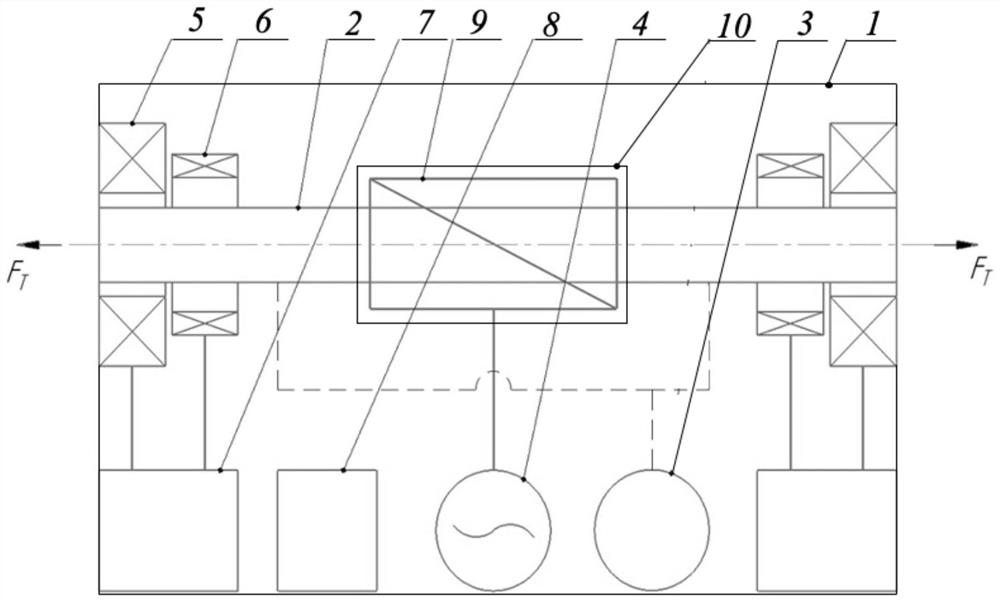

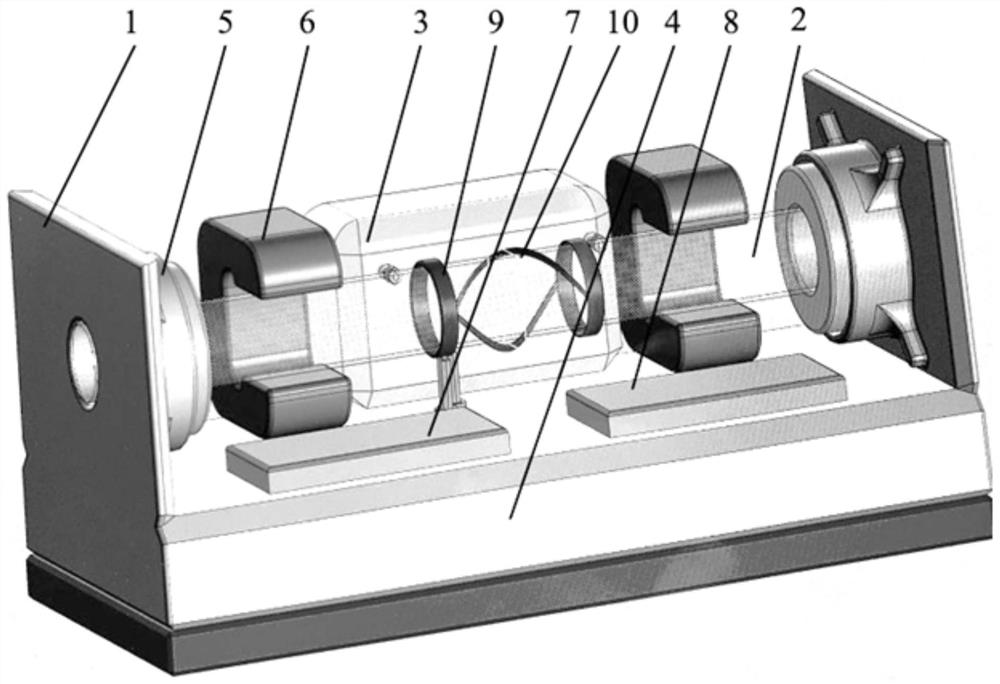

[0021] The claimed thruster is bidirectional and consists of the following components, which function as follows:

[0022] - The gas discharge chamber (2) is rigidly connected to the propeller rigid structural part (1). The gas discharge chamber (2) is made of a dielectric material in the form of a cylinder with walls, the thickness of which can vary, however there is a cylindrical path through the inside of the gas discharge chamber (2), eg on the axis of the cylinder. On the outside of the gas discharge chamber (2) there is an antenna (9) for generating an electromagnetic field within the gas discharge chamber (2) for propellant ionization. Each of the opposite end faces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com