Stainless steel multifunctional meter front valve

A multi-functional watch, stainless steel technology, applied to multi-way valves, valve details, valve devices, etc., can solve the problems of easy-wear sealing effect, laborious opening and closing of the valve stem, etc., achieve good sealing effect, flexible action, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

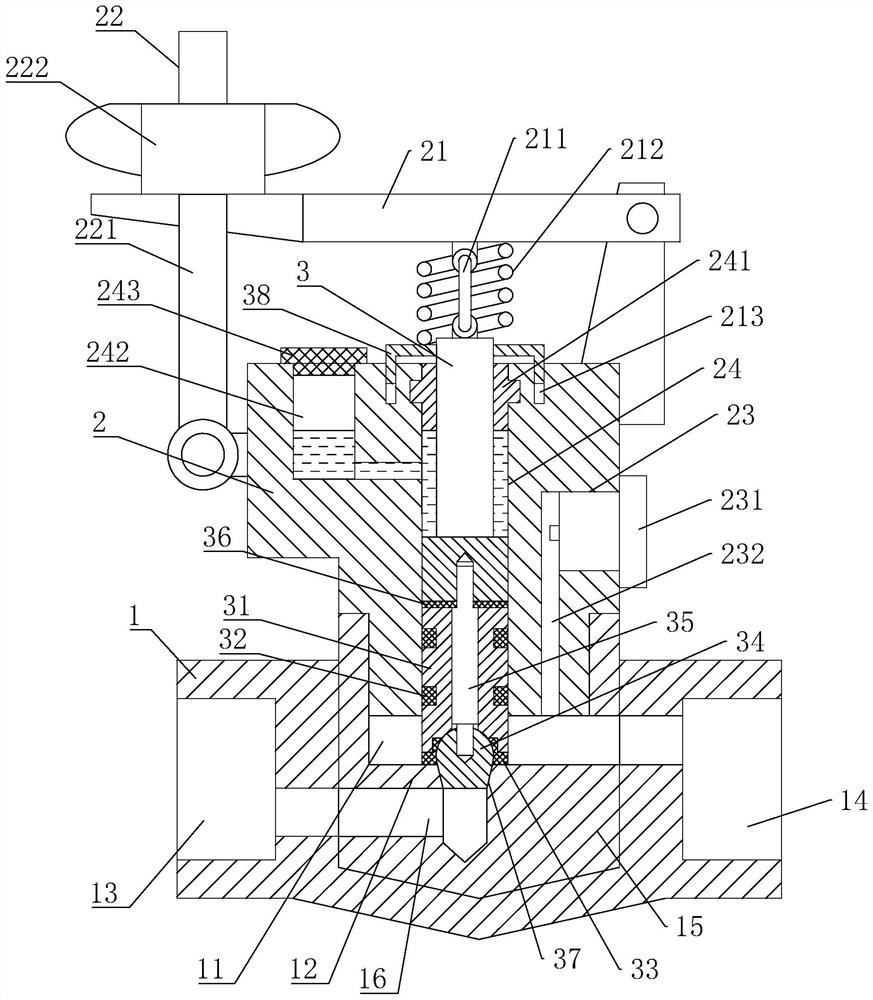

[0018] The present invention will be further described below in conjunction with the accompanying drawings:

[0019] Refer to the attached figure 1 : The stainless steel multi-function front valve in this embodiment includes a valve body 1, a bonnet 2 and a valve stem 3. The valve body 1 is provided with a valve cavity 11, the valve body 1 is made of stainless steel, and the top of the valve cavity 11 is fixedly installed The valve cap 2 has a sealing and sliding connection between the valve cap 2 and the valve stem 3. The bottom of the valve cavity 11 is provided with a valve seat 12 which is sealingly matched with the lower end of the valve stem 3, and the two ends of the valve body 1 are respectively provided with the valve cavity 11. The inlet channel 13 and the outlet channel 14 communicate with each other, the lower end of the valve stem 3 is provided with a sealing section 31, the outer wall of the sealing section 31 is provided with an annular groove, the annular groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com