Intelligent supervision system and supervision test method for electric power oil

A monitoring system, a technology for power oil consumption, applied in forecasting, data processing applications, instruments, etc., can solve the problems of inconvenient trend analysis, inability to continuously monitor each oil consumption part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the above objects, features and advantages of the present invention more clearly understood, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

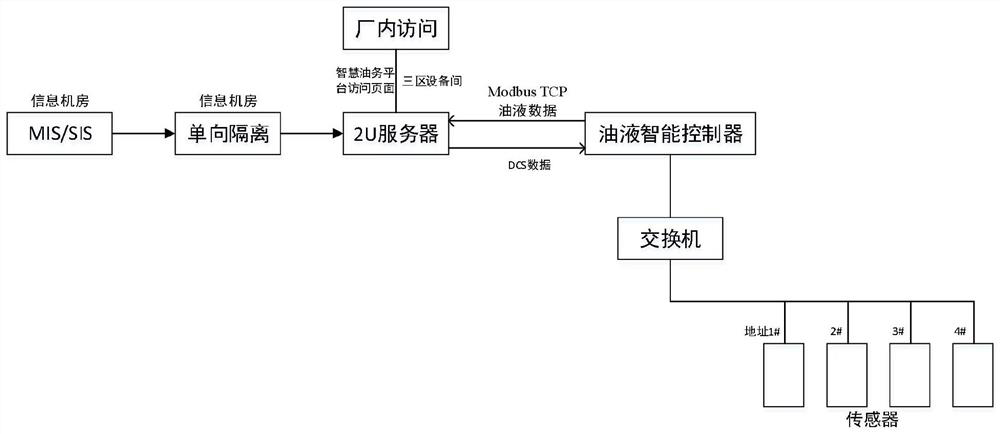

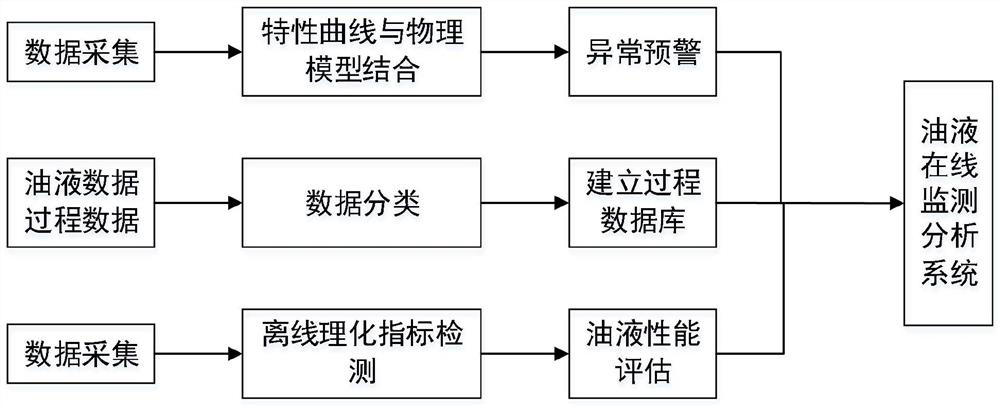

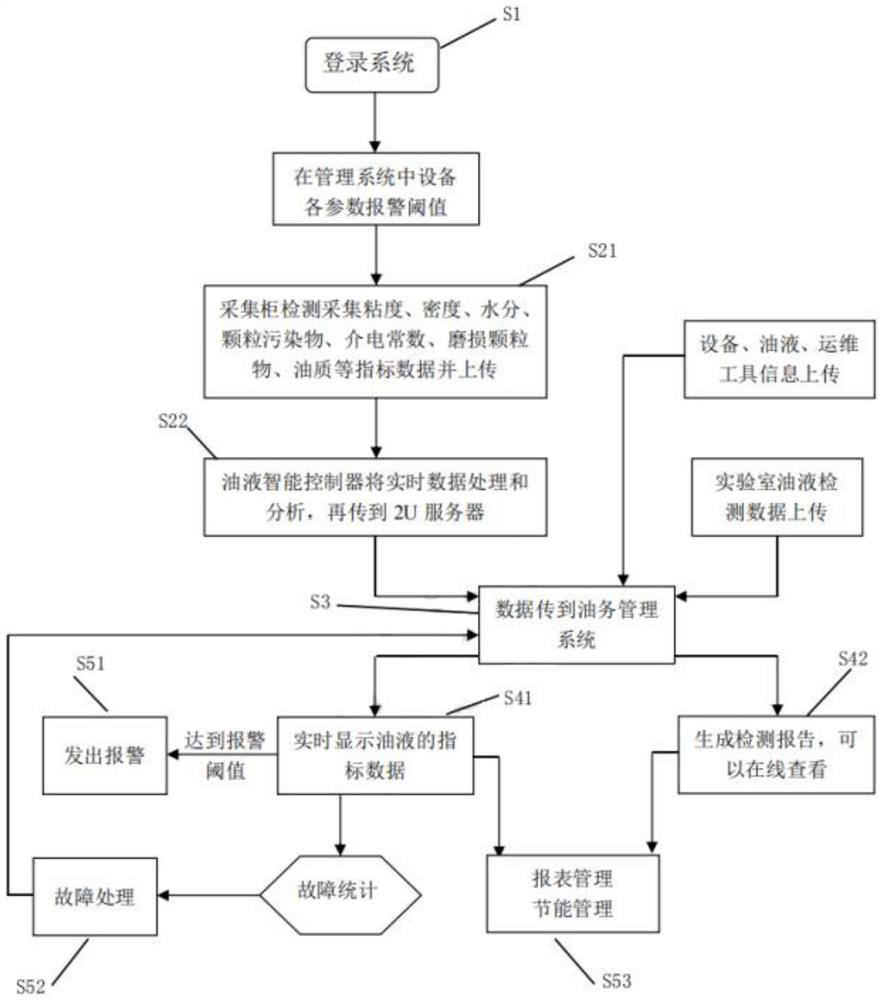

[0032] like Figures 1 to 2 As shown, this embodiment provides an intelligent supervision system for electric oil, including a data acquisition cabinet, a switch, an oil intelligent controller, a server, and a smart oil management system. The data acquisition cabinet is connected to the switch, and the switch is connected to the switch. The oil intelligent controller is connected, and the oil intelligent controller is connected to the server. The intelligent oil management system is set in the server. The server can call the data information in the MIS management information system and / or the SIS plant-level monitoring information system. The data acquisition cabinet will The collected data information is sent to the oil intelligent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com