Flexible gel driver and preparation method thereof

A driver, gel technology, applied in piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc. Problems such as poor flexibility, to enhance the user experience, improve the output displacement and output force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

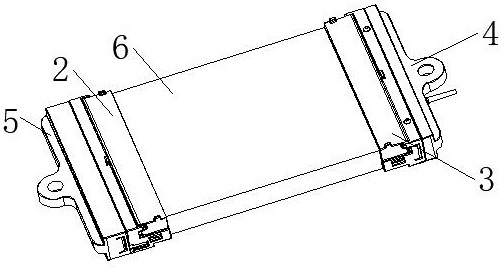

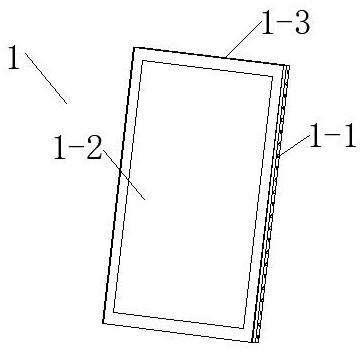

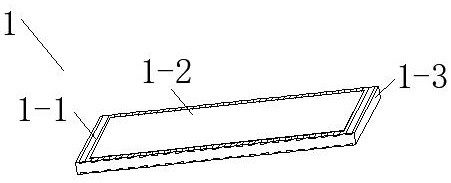

[0029] Example: as Figure 1 to Figure 10 As shown, a flexible gel driver is mainly composed of a male end 2 having a male end leading electrode 2-4, a female end 3 having a female end leading electrode 3-4, and a gel driving unit 1. The gel driving unit described above is composed of 1 is located between the above-mentioned male end 2 and the above-mentioned female end 3, and the above-mentioned gel driving unit 1 includes an electroactive polymer main body 1-3, a flexible cathode and anode 1-2 and a constraining member 1-1. When the restraining member 1-1 is a restraining strip, the restraining member 1-1 is attached to both sides of the surface of the electroactive polymer body 1-3, and the flexible cathode and anode 1-2 are attached to the surface of the restraining member 1-1. . When the restraining member 1-1 is a fiber, the restraining member 1-1 is embedded in the electroactive polymer body 1-3, and the flexible cathode and anode 1-2 are attached to the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com