An ultrasonic wire drawing vibrator with a single drive to achieve orthogonal composite vibration

A composite vibration and ultrasonic technology, used in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, medical science, etc., can solve the problems of small output displacement, difficult heat dissipation, poor applicability, etc. The effect of high electromechanical coupling efficiency, reduced auxiliary equipment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

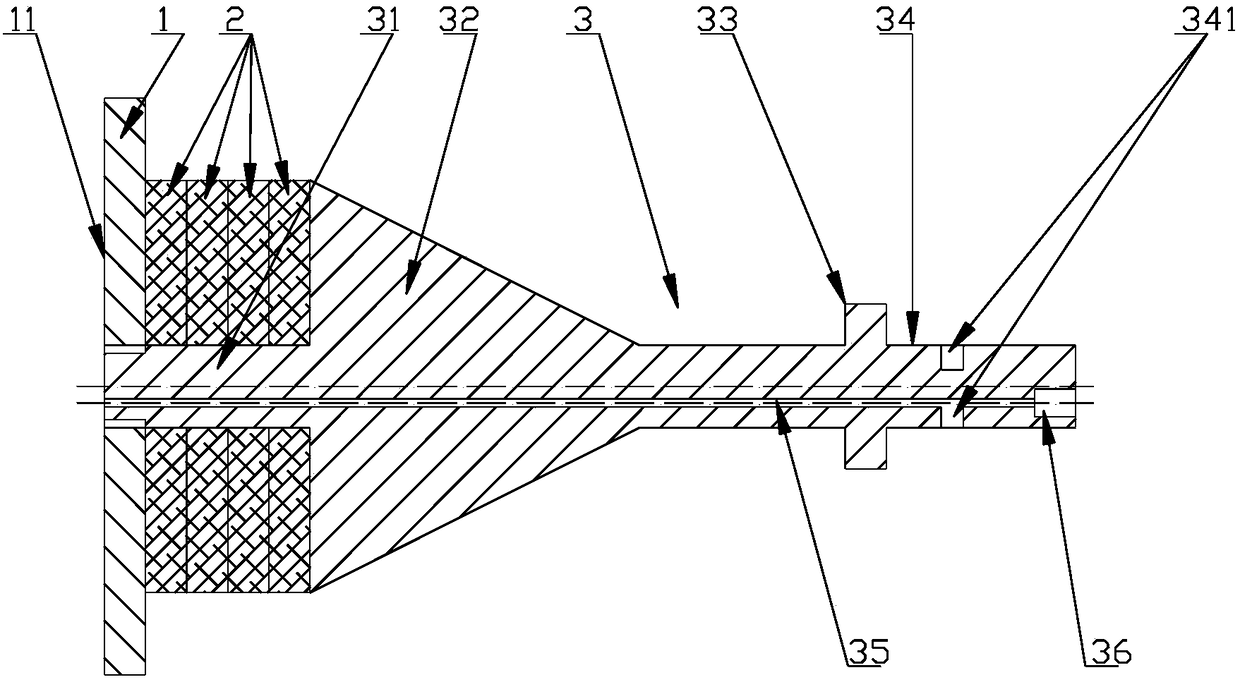

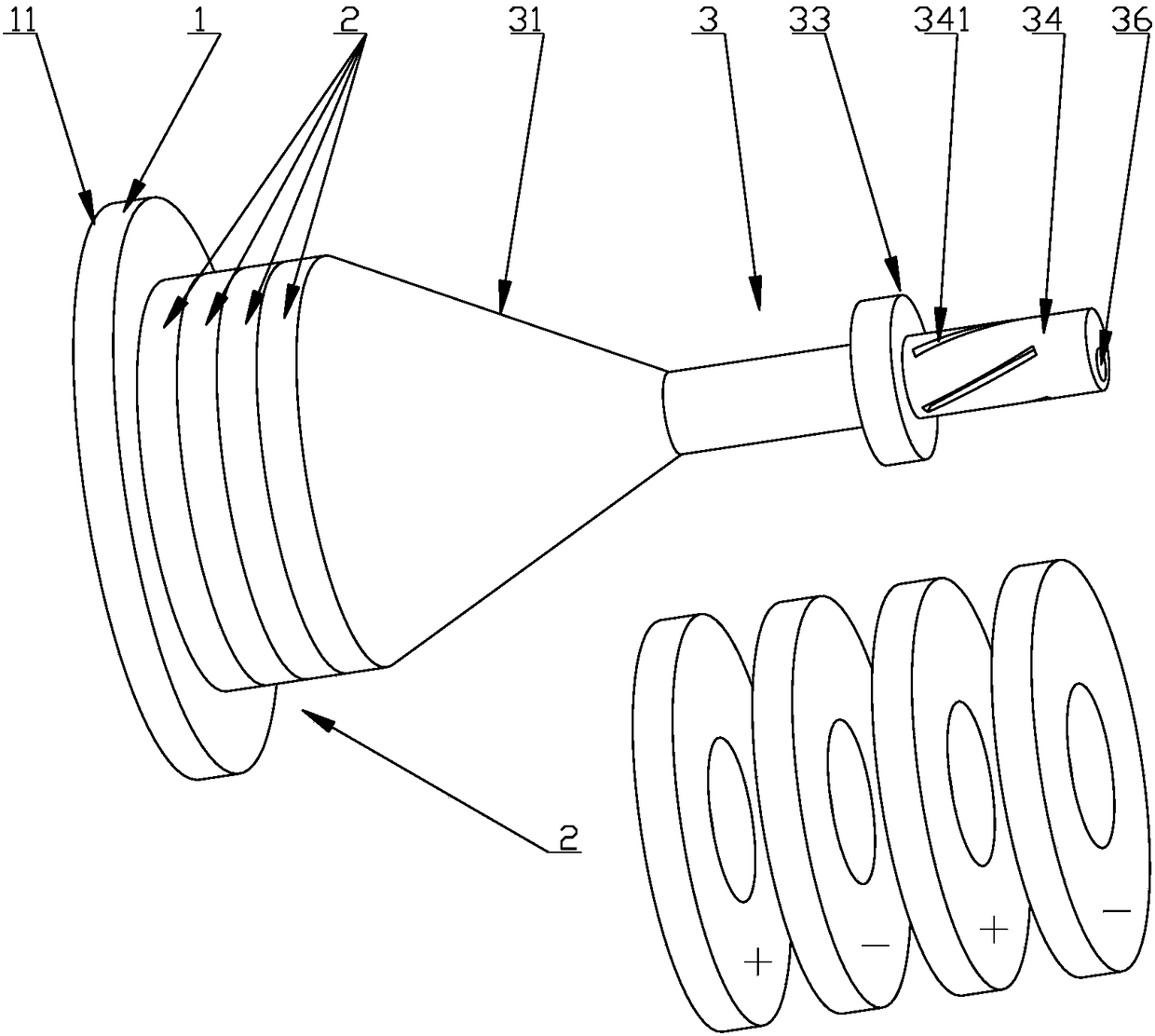

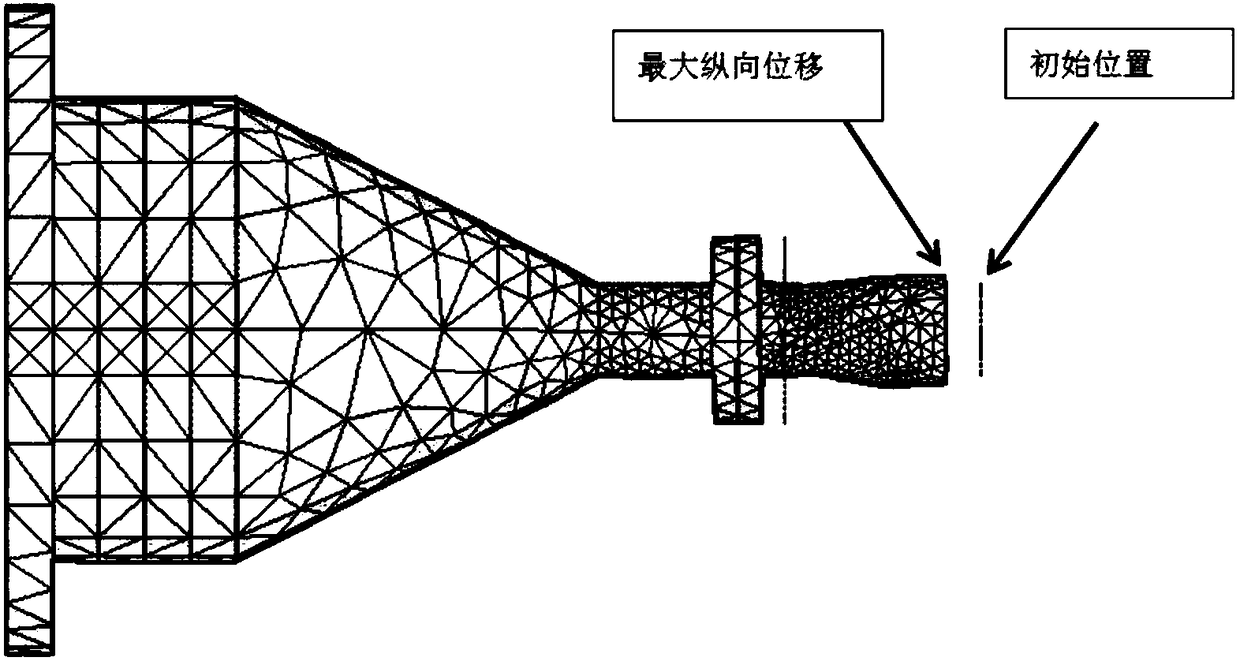

[0031] figure 1 It is a cross-sectional view of the ultrasonic drawing vibrator with a single drive to realize orthogonal compound vibration according to the present invention; figure 2 It is a schematic diagram of the geometry of the ultrasonic drawing vibrator with a single drive to realize orthogonal composite vibration and a schematic diagram of the polarization mode of the piezoelectric ceramic sheet according to the present invention; image 3 It is the orthogonal compound vibration mode of the ultrasonic wire drawing vibrator realizing the orthogonal compound vibration by single driving in the present invention. to combine Figure 1 to Figure 3 To describe the present invention in detail, the orthogonal composite ultrasonic wire drawing vibrator includes a rear end cover nut 1, four piezoelectric ceramic sheets 2 and a composite horn 3; the rear end surface of the rear end cover nut 1 is an ultrasonic drawing die installation surface 11; In this embodiment, the insta...

Embodiment 2

[0035] The difference between embodiment 2 and embodiment 1 is that the composite horn 3 is a sub-assembly rod, wherein the tapered rod 32 is provided with threads, and is connected with the cylindrical rod 34 through threads. The specific structure is as follows Figure 7 As shown, other components and connections are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com