Conductive bar with high thermal conductivity and forming method thereof

A technology with high thermal conductivity and forming method, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of affecting the service life of conductive strips, affecting the safety of electrical appliances, and burning out the connections of conductive strips. The effect of protecting conductive strips, reducing heat accumulation and avoiding burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be described in further detail below with reference to the embodiments and the accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation on the protection scope of the present invention.

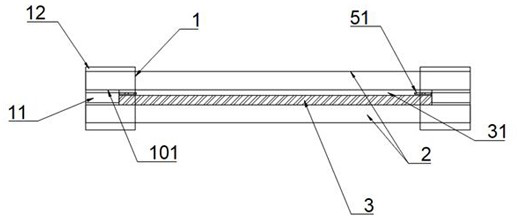

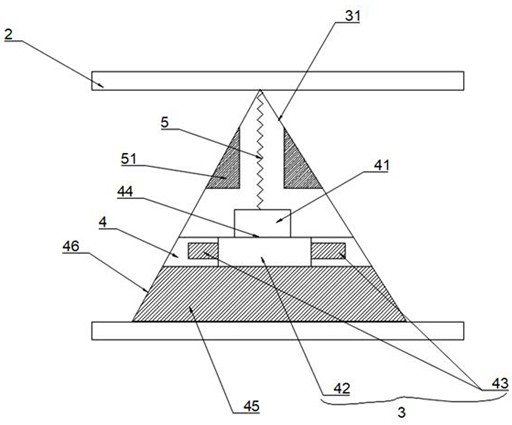

[0021] like Figure 1 to Figure 2 It is a specific embodiment of the present invention, and its structure also includes two insulating sleeve openings 1 and two silicone rubber strips 2, wherein one silicone rubber strip 2 is provided with two copper guide rails 3, and the other silicone rubber strip 2 is provided with two copper guide rails 3. There are two copper sliding grooves 31, the copper guide rail 3 is slidably arranged on the copper sliding groove 31, and a safe distance is maintained between the two silicone rubber strips 2. The interior of the insulating sleeve 1 is divided into two fixing grooves 12. The length of the cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com