Solar charger integrated with load output control

A solar charger, load output technology, applied in current collectors, output power conversion devices, control/regulation systems, etc., can solve the problems of users who are not informed in time, difficult to start smoothly, and battery overcharged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

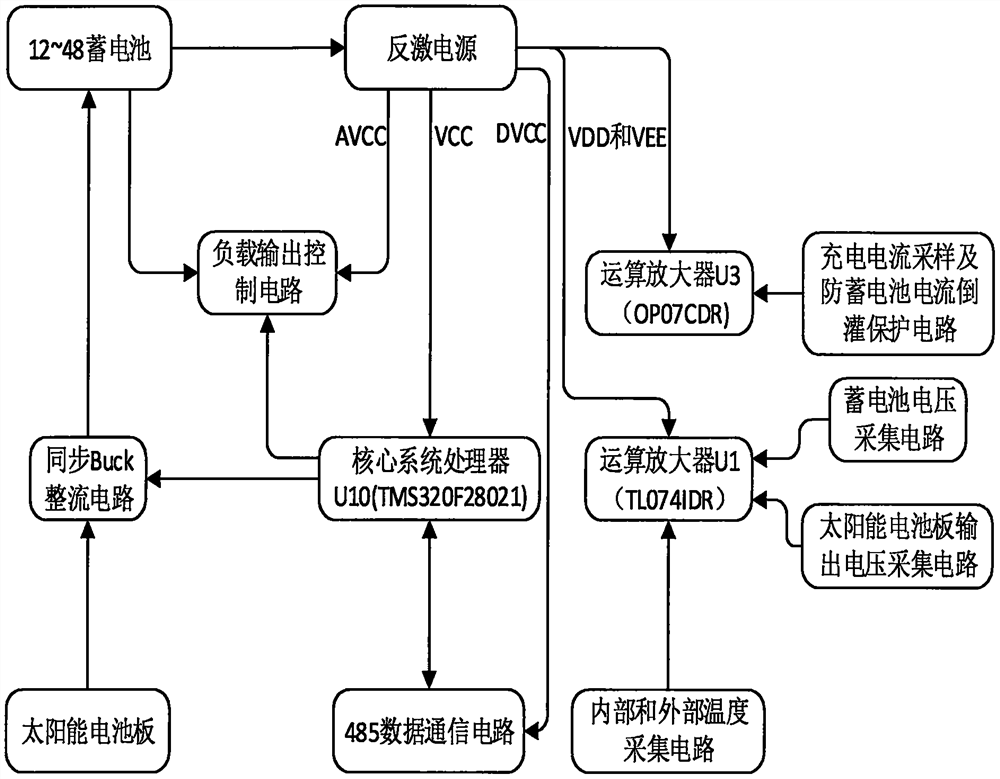

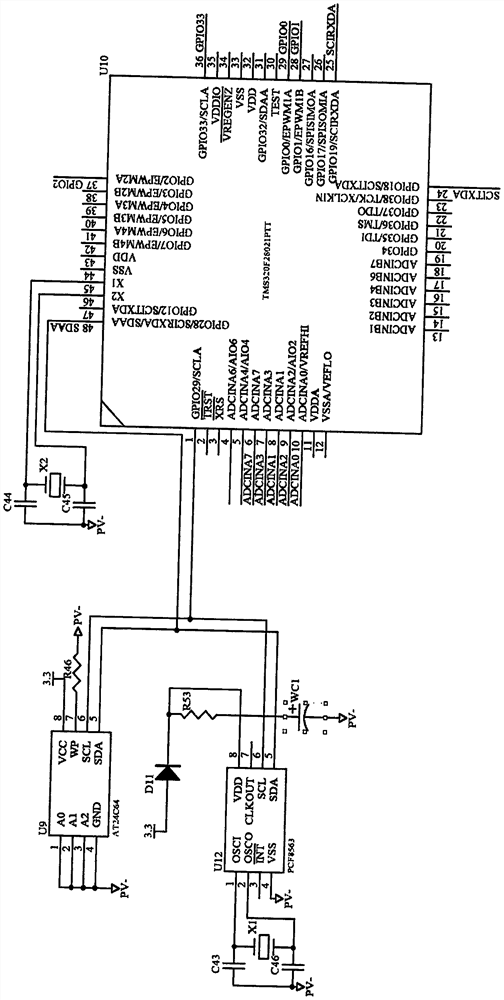

[0030] like figure 1As shown, this embodiment includes a battery, a solar panel, a flyback power supply based on the UC2845 control chip U4, a processor U10 with the chip model TMS320F28021, a synchronous Buck rectifier circuit based on the IR2110S driver chip U8, and a load output control circuit. circuit, 485 data communication circuit, charging current sampling circuit, battery voltage sampling circuit and solar panel output voltage sampling circuit, wherein:

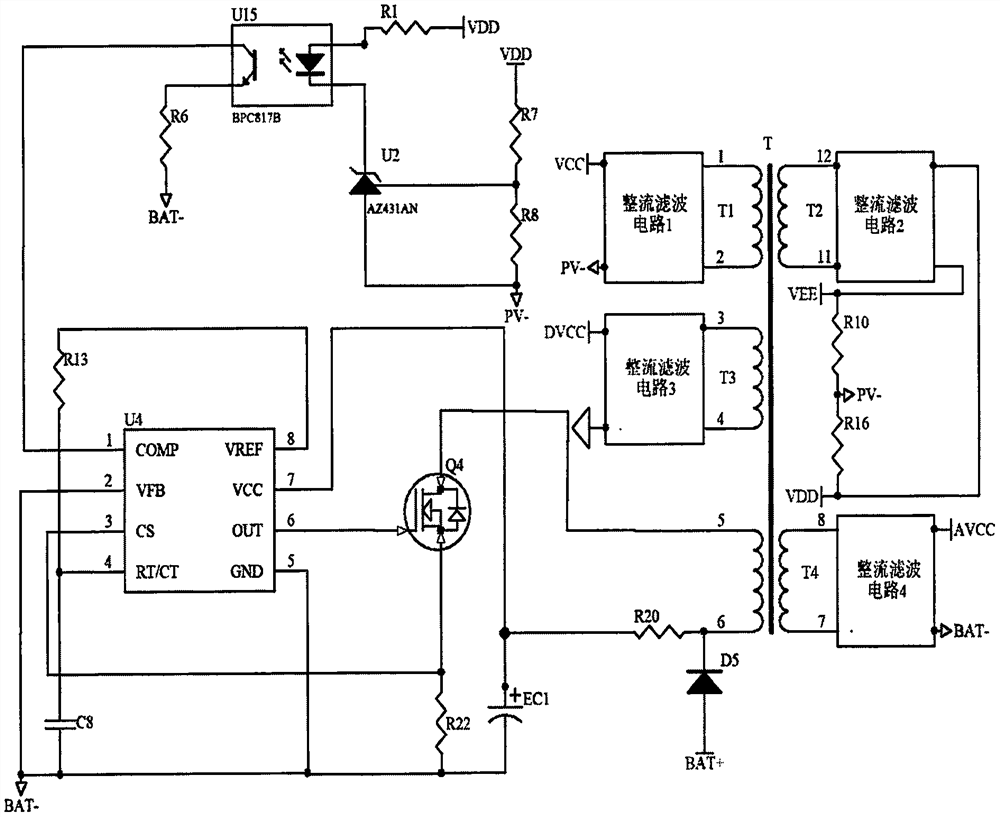

[0031] (1) If figure 2 As shown, the power input terminal of the flyback power supply is connected to the output terminal of the battery, and the output terminals of the flyback power supply respectively output the analog power supply voltage AVCC, the digital circuit power supply voltage VCC, the positive digital power supply voltage DVCC and the positive and Negative power suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com