Redwood furniture production line

A technology for mahogany furniture and production lines, which can be used in wood processing appliances, wood impregnation, manufacturing tools, etc., and can solve problems such as cumbersome implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

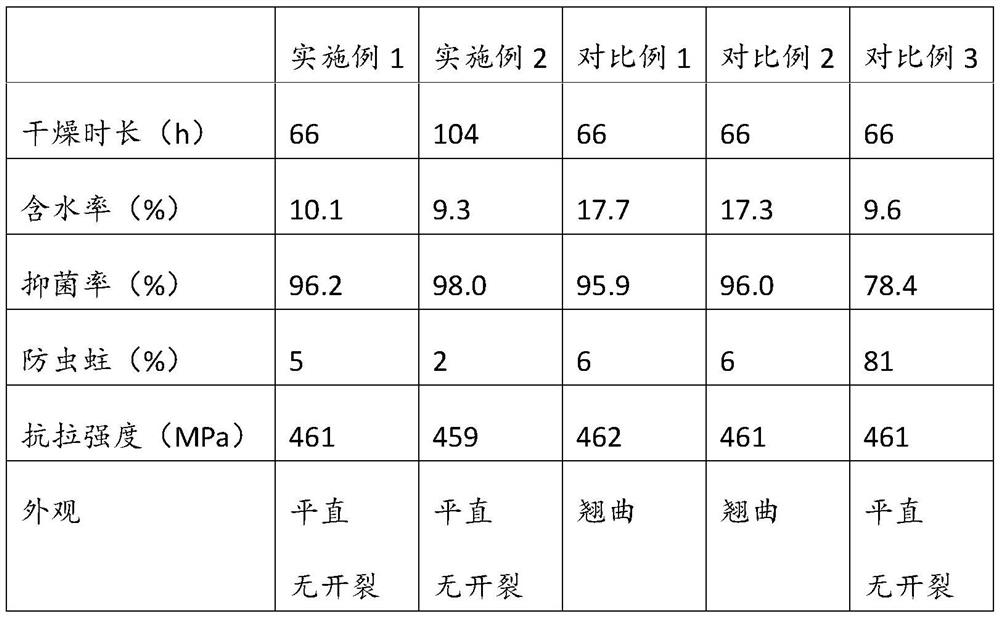

Embodiment 1

[0069] The present embodiment provides a mahogany furniture production line, and the specific process is:

[0070] D1. Raw material preparation:

[0071] Configure the first pretreatment aqueous solution: in the environment of 50 ℃, add 8 mol / L ammonia water to the 0.2 mol / L copper sulfate solution dropwise, in the process, a precipitate is formed first, and then the precipitate disappears. The molar ratio of copper sulfate and ammonia water used is 1:7.5 (in terms of nitrogen in ammonia water); add sodium chloride to it and dilute to a concentration of 7wt% of sodium chloride, and the concentration of copper ammine complex is 12mmol / L (in terms of the number of copper atoms); cooling After that, put the prepared first pretreatment aqueous solution into the first soaking tank.

[0072] Configure the second pretreatment aqueous solution: mix sodium chloride, water, oxalic acid and quercetin (CAS: 117-39-5) to obtain a concentration of sodium chloride of 7wt%, quercetin of 2mmo...

Embodiment 2

[0083] The present embodiment provides a mahogany furniture production line, and the production process is:

[0084] Raw material preparation:

[0085] Configure the first pretreatment aqueous solution: in the environment of 50 ℃, add 8 mol / L ammonia water to the 0.2 mol / L copper sulfate solution dropwise, in the process, a precipitate is formed first, and then the precipitate disappears. The molar ratio of copper sulfate and ammonia water used is 1:7.5 (in terms of nitrogen in ammonia water); add sodium chloride to it and dilute to a concentration of 20% by weight of sodium chloride, and the concentration of copper ammine complex is 10 mmol / L (in terms of the number of copper atoms); cooling Get it later. Put the prepared first pretreatment aqueous solution into the first soaking tank.

[0086] Configure the second pretreatment aqueous solution: mix sodium chloride, water, oxalic acid and quercetin (CAS: 117-39-5) to obtain a concentration of sodium chloride of 7wt%, querce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com