Composite plastic woven bag production bag making equipment and bag making process

A technology for compounding plastic and woven bags, applied in bag making operations, flexible container manufacturing, paper/cardboard containers, etc., can solve the problems of woven bags, loose woven bags in rolls, repeated feeding, etc., so as to reduce production costs. , Improve the applicability, avoid the effect of wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

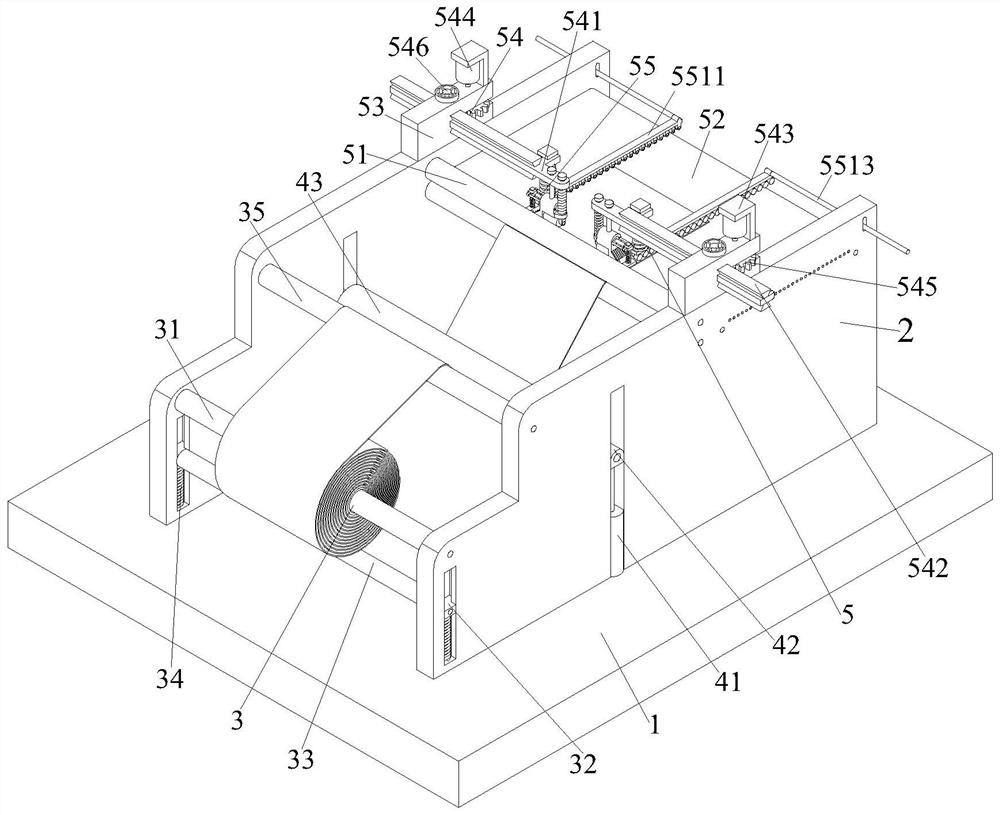

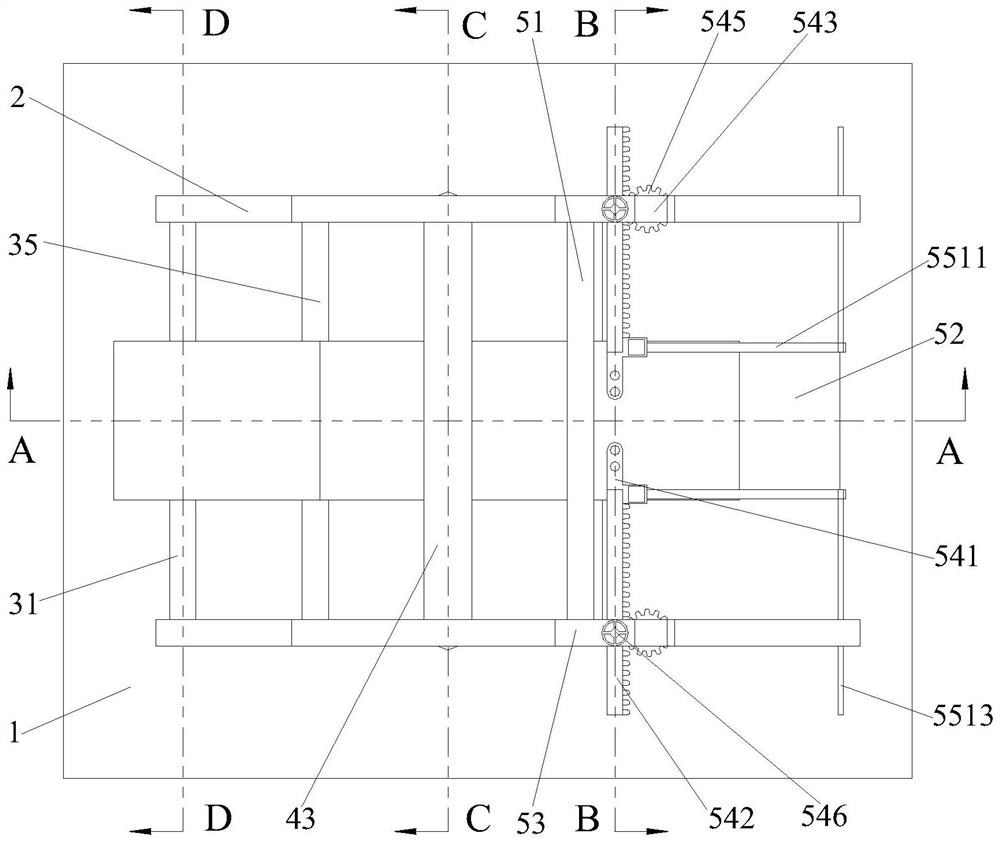

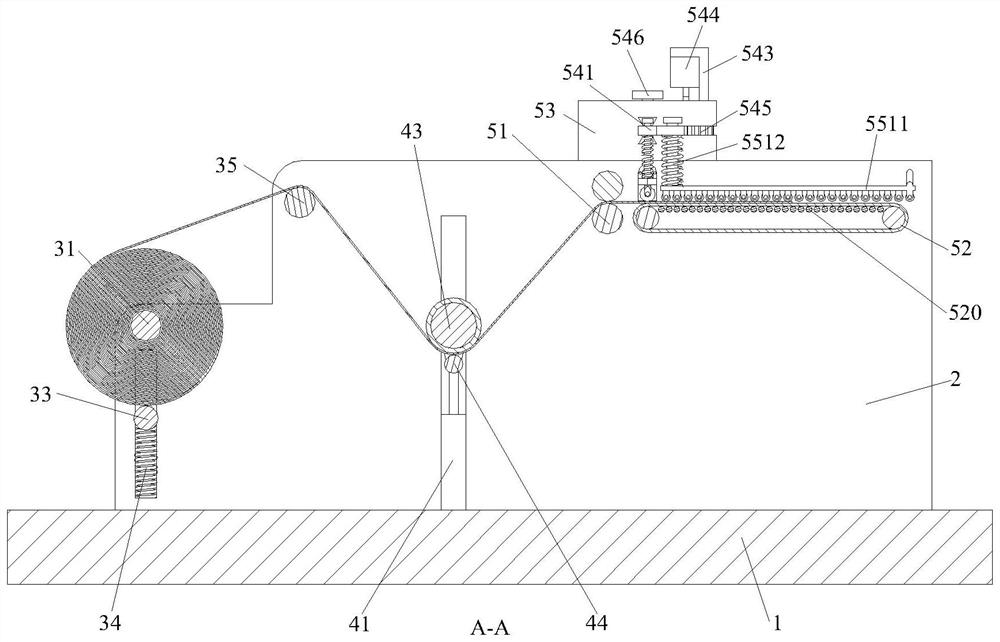

[0040] In order to make the technical means, creation features, achievement goals and effects realized by the present invention easy to understand and understand, the following combination Figure 1 to Figure 10 , the present invention will be further elaborated.

[0041] see figure 1 , figure 2 and Figure 5 , a composite plastic woven bag production bag making equipment, comprising a bottom plate 1, the upper end of the bottom plate 1 is symmetrically installed with a side plate 2 front and rear, the inner left end of the side plate 2 is installed with a feeding device 3, and the right side of the feeding device 3 is provided with a lift The device 4, the lifting device 4 is installed on the inner side of the middle part of the side plate 2, and the flattening device 5 is installed on the right end of the inner side of the side plate 2.

[0042] see figure 1 , image 3 and Image 6 , the feeding device 3 includes a placing rod 31 installed on the left end of the inner s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap