Drying device for capacitor shell processing based on capacitor production

A drying device and capacitor technology, applied in the direction of drying/impregnation machine, etc., can solve the problems that the upper and lower sides of the capacitor shell cannot be dried at the same time, the capacitor shell is easy to pile up, and the unloading is easy to cause wear, so as to avoid insufficient drying, Reduce buffering and avoid collision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

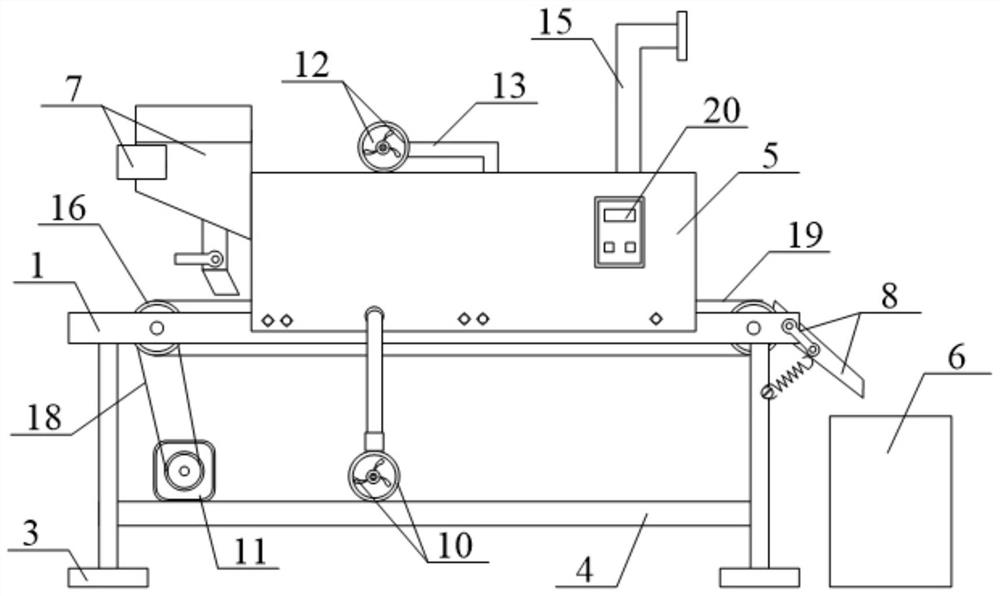

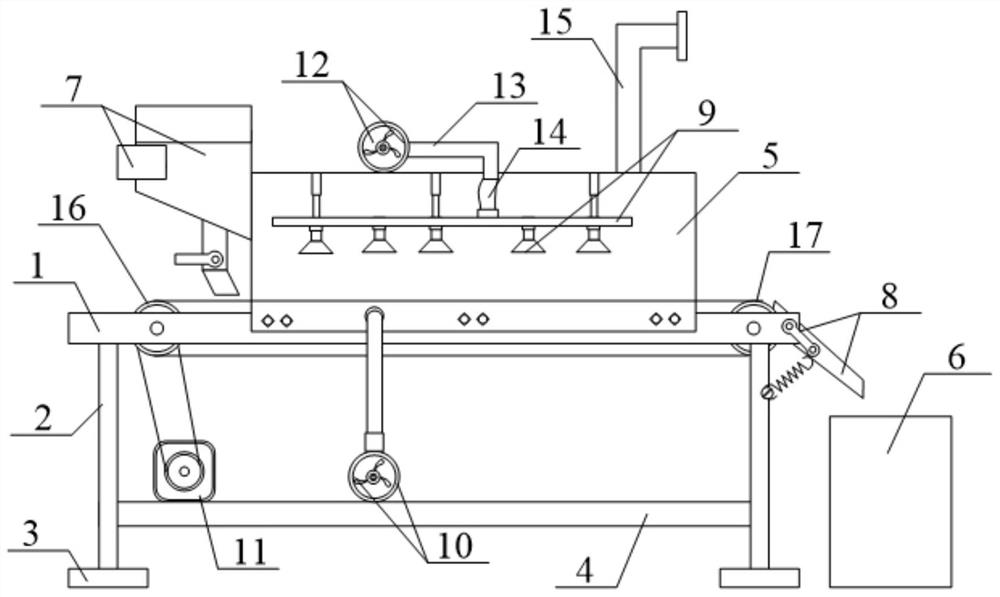

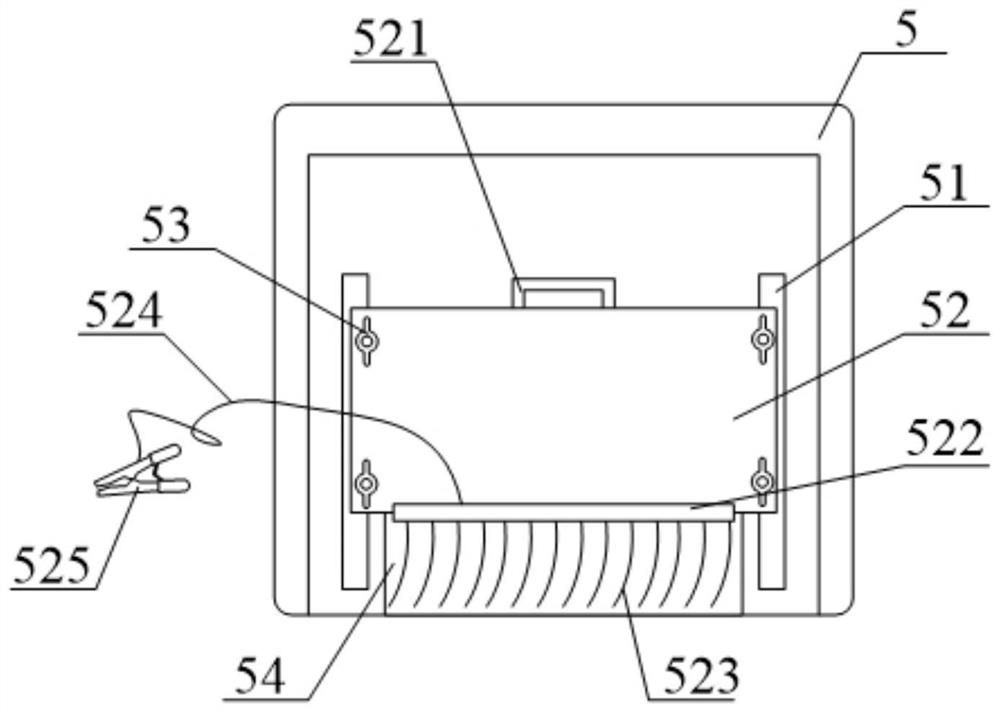

[0041] as attached figure 1 to the attached figure 2 As shown, the present invention provides a drying device for capacitor shell processing based on capacitor production, including a support frame 1, a support column 2, a stable base 3, a horizontal support plate 4, a drying box 5, and a collection box 6. The capacitor shell distribution bucket assembly 7, the anti-collision buffer blanking plate assembly 8, the liftable upper drying tube assembly 9, the fixed lower drying tube assembly 10, the power motor 11, the upper hot air blower 12, the lower hot air duct 13 , telescopic hose 14, steam discharge nozzle 15, drive roller 16, driven roller 17, drive belt 18, drying conveyor belt 19 and control box 20,

[0042] One end of the support column 2 is bolted to the lower four corners of the support frame 1 respectively, and the other end is bolted to the upper middle position of the stable base 3; the transverse support plate 4 is bolted to the inner side of the two support col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com