Automatic sewage suction micro-irrigation gravel filter

A technology of sand filter and automatic sewage suction, which is applied in the direction of gravity filter, loose filter material filter, filter separation, etc., and can solve the problems of decreased filtration flow rate, long backwashing time, and reduced water resource utilization efficiency. To achieve the effect of improving sewage discharge capacity, improving sewage holding capacity, and improving unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

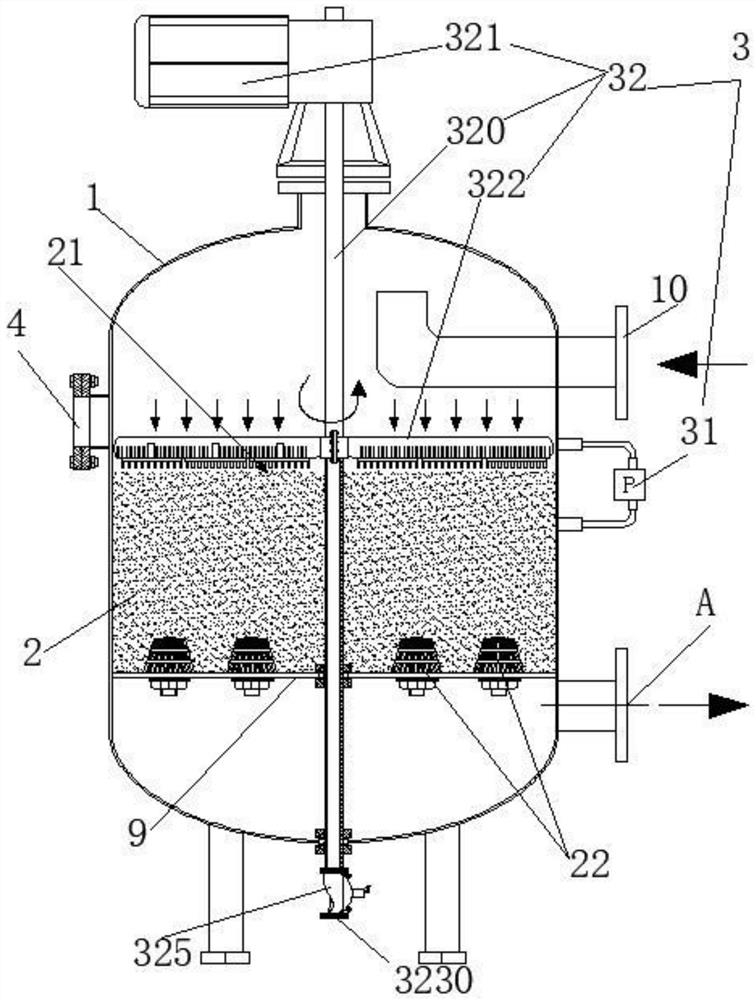

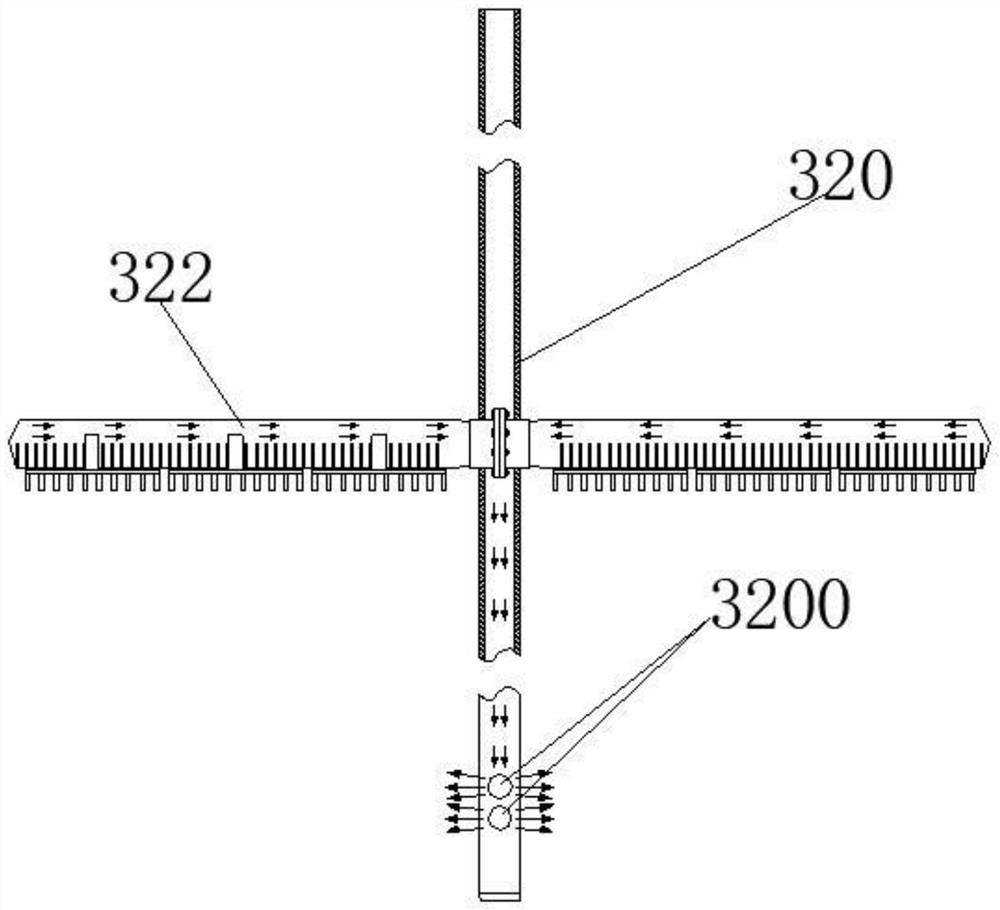

[0029] refer to figure 1 , the present invention provides an automatic dirt-absorbing micro-filling sand and gravel filter, the filter includes a tank body 1, a filter layer 2 arranged in the tank body 1, and a filter layer 2 arranged on both sides of the filter layer 2 The inlet 10 and the outlet 11, the filter layer 2 includes a filter surface 21 close to the inlet side, and also includes: a cleaning component 3, the cleaning component 3 includes a filter for detecting the pressure difference on both sides of the filter surface 21. A detection unit 31 and a sewage discharge unit 32 connected to the detection device 31, the sewage discharge unit 32 includes a rotating shaft 320 rotatably arranged on the tank body 1, a driving device 321 for driving the rotating shaft 320 to rotate around the axis, and At least one sewage pipe 322 adapted to the filter surface 21 and a sewage channel 323 communicated with at least one of the sewage pipes 322. The sewage pipe 321 is provided wi...

Embodiment 2

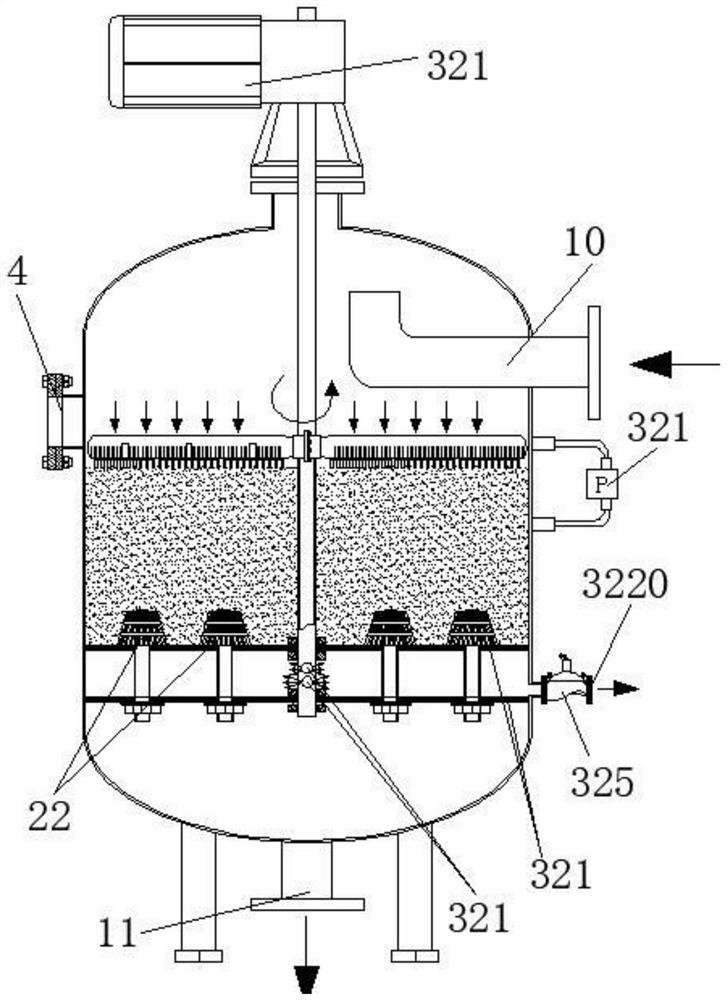

[0038] refer to figure 2 , the present invention provides an automatic dirt-absorbing micro-filling sand and gravel filter, the filter includes a tank body 1, a filter layer 2 arranged in the tank body 1, and a filter layer 2 arranged on both sides of the filter layer 2 The inlet 10 and the outlet 11, the filter layer 2 includes a filter surface 21 close to the inlet side, and also includes: a cleaning assembly 3, as a further improvement, the difference between this embodiment and the first embodiment is that the The tank body is provided with two support plates 9 at intervals, the filter layer 2 is arranged on one of the support plates, and the rotating shaft 320 is provided with a connection between the infusion channel and the area between the two support plates 9. The communication port 3200, the sewage channel 323 includes the area between the infusion channel and the two support plates 9, the sewage outlet 3230 is provided on the tank body and communicates with the are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com