Treatment method of hydrogen sulfide gas in underground confined space

A closed space and treatment method technology, applied in the direction of chemical instruments and methods, separation methods, cleaning methods and utensils, can solve the problems of inconvenient operation and olfactory pollution in the surrounding area, so as to solve the inconvenient operation and reduce secondary pollution , the effect of reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

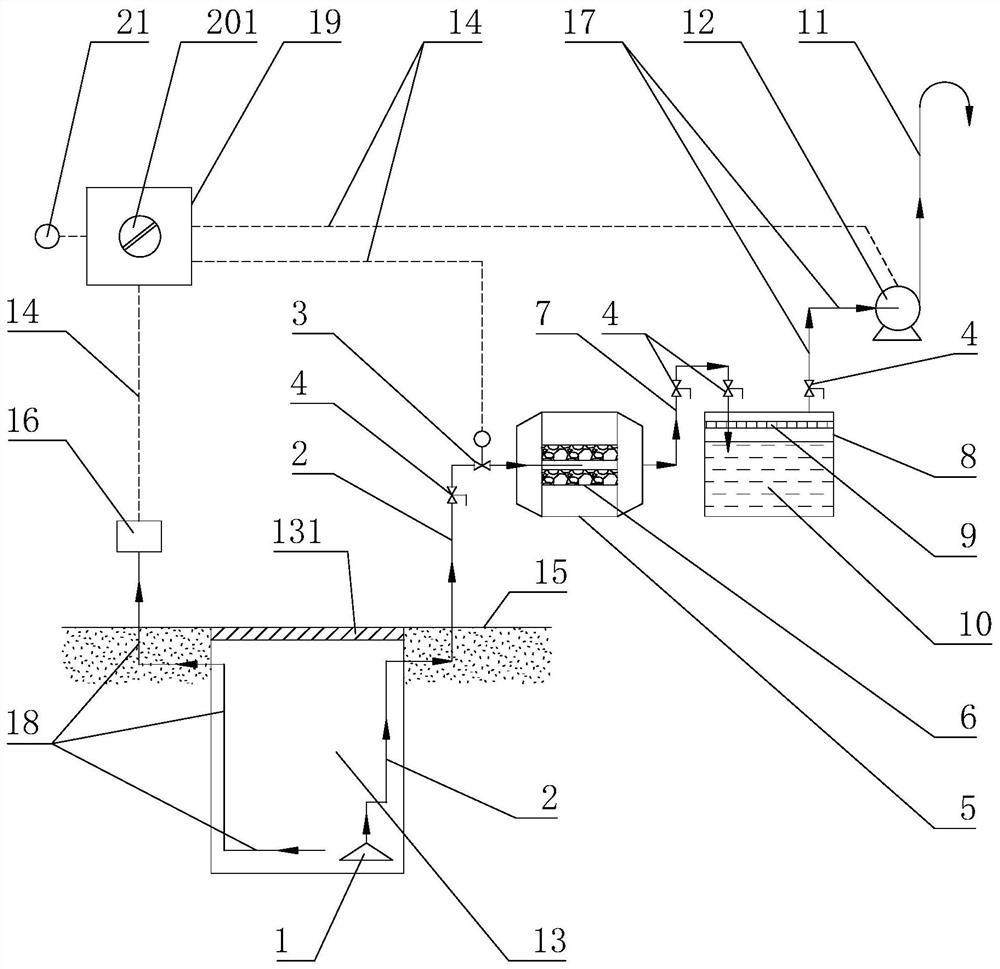

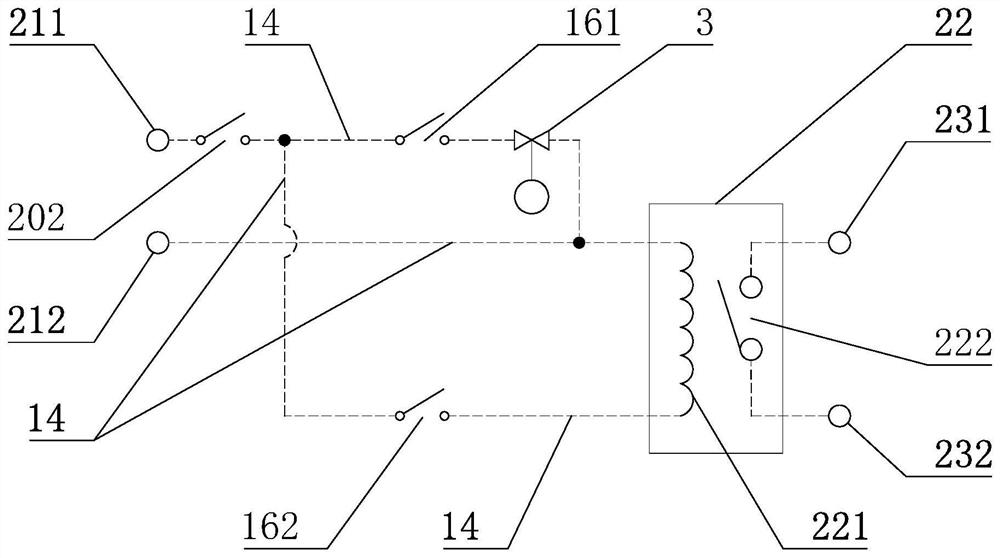

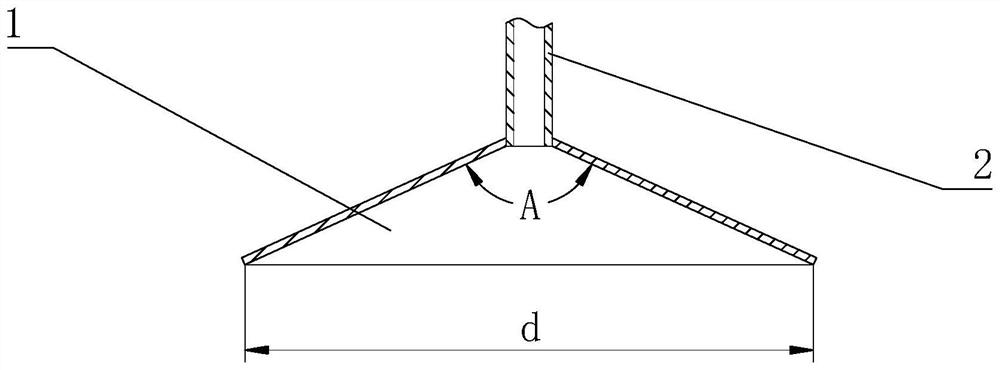

[0013] see figure 1 and figure 2 , the hydrogen sulfide gas processing device in the underground closed space of the present invention (referred to as the device of the present invention), comprising a hydrogen sulfide gas detector 16, a hydrogen sulfide gas detector sampling pipe 18, a gas collection cover 1, a suction gas delivery pipe 2, The adsorption box 5, the processing gas delivery pipe 7, the processing container 8, the processing gas output pipe 17, the vacuum pump 12, and the circuit system. The top of the underground closed space 13 is provided with a cover plate 131 , and the upper surface of the cover plate 131 is flush with the ground 15 . The underground closed space 13 communicates with the atmosphere through gaps, openings, and the like.

[0014] The inlet of the sampling pipe 18 of the hydrogen sulfide gas detector is located at the lower part of the underground closed space 13 , and the inlet is the detection position of the hydrogen sulfide gas detector...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap