Furniture solid wood panel punching device

A technology of punching device and solid wood, which is applied to fixed drilling machines, drilling machines supported by operators, etc., can solve problems such as difficult boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

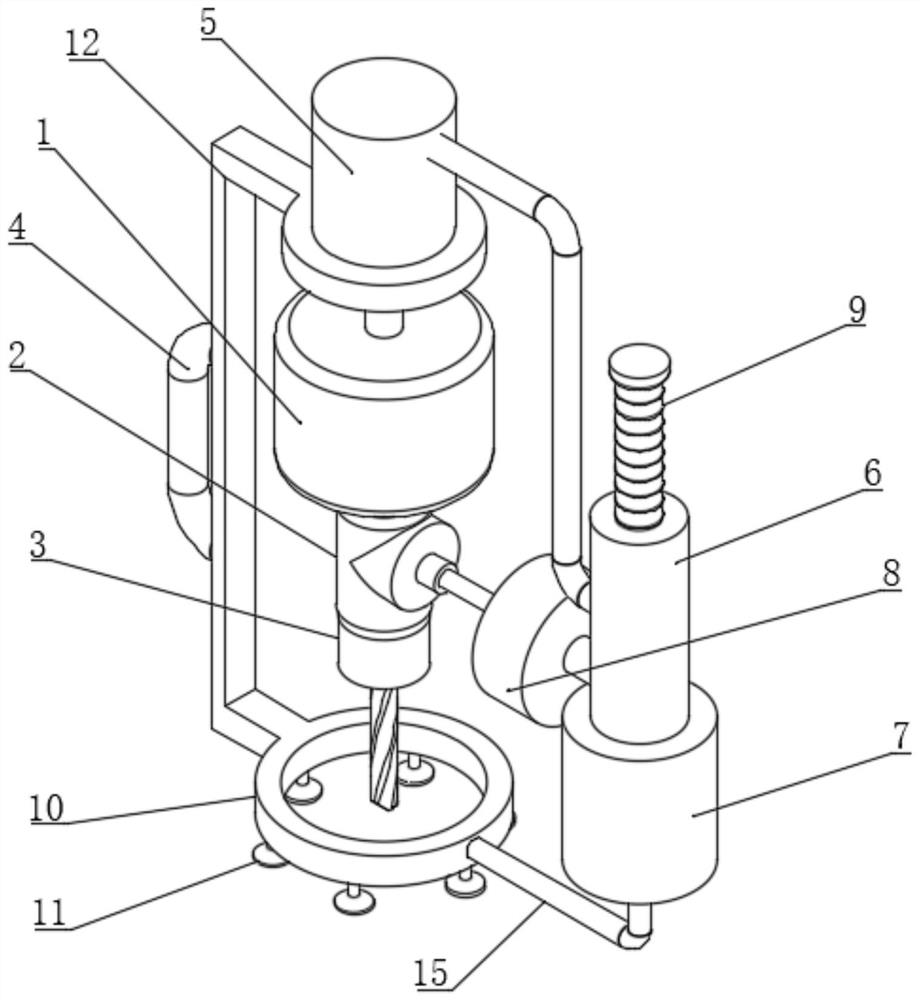

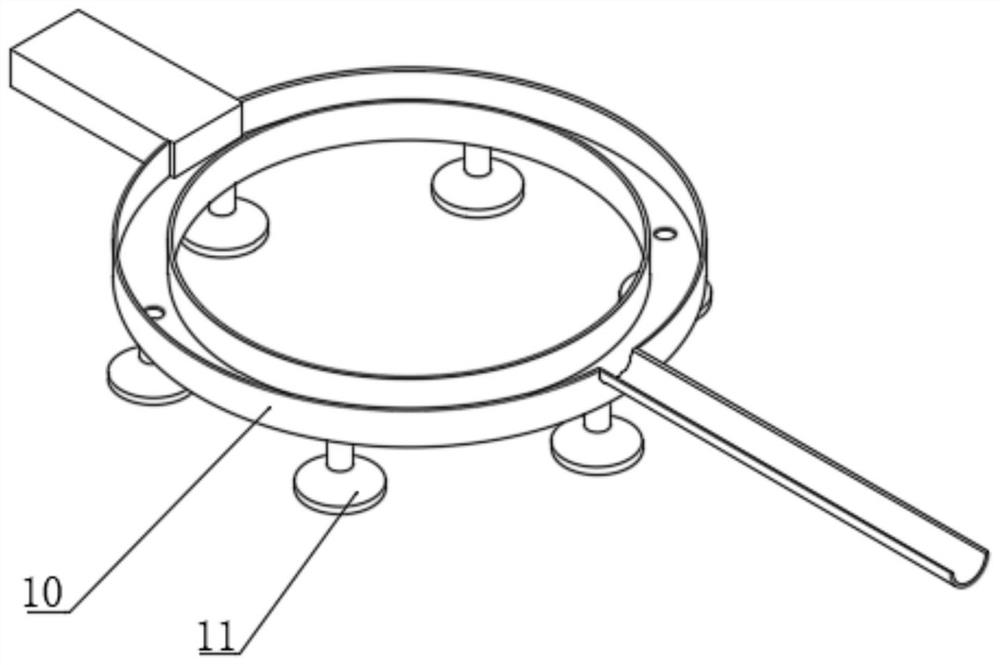

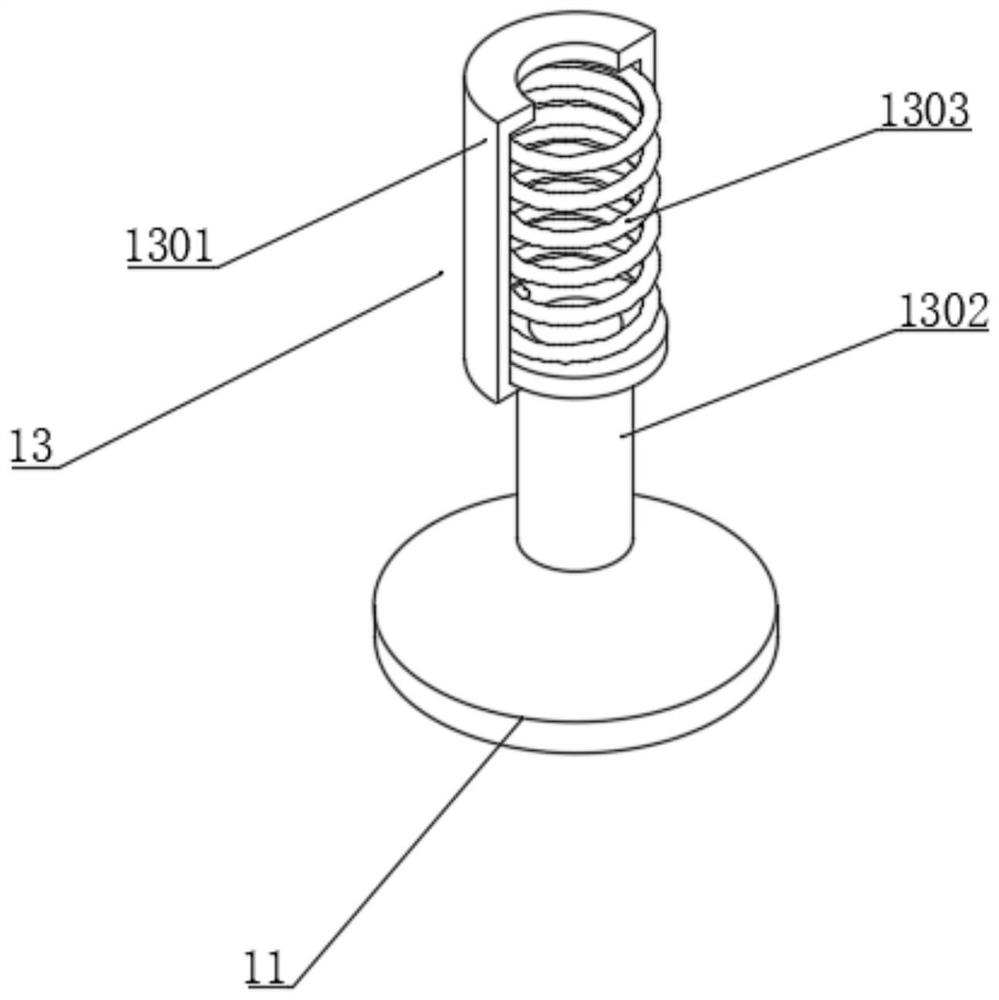

[0030] like Figure 1-3 As shown, a device for punching a solid wood board for furniture includes a drilling rig 1, which is connected to a frame 12, the frame 12 is fixedly connected with a pressing mechanism, and the pressing mechanism includes a pressing ring 10 connected to the bottom end of the frame 12. , the bottom of the pressing ring 10 is fixedly connected with a plurality of suction cups 11 in an annular array with the axis of the pressing ring 10 as the center. The push cylinder 5 on the frame 12 is connected in reverse driving, and the piston rod of the push cylinder 5 is fixedly connected with the drilling machine 1; The connecting pipe 13 includes a sleeve 1301 fixedly connected with the pressing ring 10, a sliding pipe 1302 is slidably connected in the sleeve 1301, and the top of the sliding pipe 1302 is connected with the inner top of the sleeve 1301 by a compression spring 1303. The bottom end is fixedly connected to the suction cup 11 .

[0031] During the...

Embodiment 2

[0033] like Figure 1-4, a furniture solid wood board drilling device, including a drilling machine 1, the drilling machine 1 is connected to a frame 12, the frame 12 is fixedly connected with a pressing mechanism, and the pressing mechanism includes a pressing ring 10 connected to the bottom end of the frame 12, pressing The bottom of the clamping ring 10 is fixedly connected with a plurality of suction cups 11 in an annular array with the axis of the clamping ring 10 as the center. The push cylinder 5 on the 12 is connected in reverse driving, and the piston rod of the push cylinder 5 is fixedly connected with the drilling rig 1; the suction cup 11 includes a connecting pipe 13 fixedly connected with the pressing ring 10, and the bottom end of the connecting pipe 13 is fixedly connected with a rubber made of The suction cup 11; the connecting pipe 13 includes a sleeve 1301 fixedly connected with the pressing ring 10, a sliding pipe 1302 is slidably connected in the sleeve 13...

Embodiment 3

[0036] like Figure 1-6 As shown, a device for punching a solid wood board for furniture includes a drilling rig 1, which is connected to a frame 12, the frame 12 is fixedly connected with a pressing mechanism, and the pressing mechanism includes a pressing ring 10 connected to the bottom end of the frame 12. , the bottom of the pressing ring 10 is fixedly connected with a plurality of suction cups 11 in an annular array with the axis of the pressing ring 10 as the center. The push cylinder 5 on the frame 12 is connected in reverse driving, and the piston rod of the push cylinder 5 is fixedly connected with the drilling machine 1; The connecting pipe 13 includes a sleeve 1301 that is fixedly connected to the pressing ring 10, and a sliding pipe 1302 is slidably connected in the sleeve 1301. The bottom end is fixedly connected to the suction cup 11, the pressing cylinder 7 and the pushing cylinder 5 are connected through the connecting cylinder 6, the middle of the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com