Horizontal double-shaft mixing devolatilization machine

A horizontal twin-shaft mixing technology, which is applied in the field of horizontal twin-shaft mixing devolatilizers, can solve problems such as material accumulation and locking of the rotating shaft, so as to improve reliability, increase heat exchange area, and improve mixing efficiency. refining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

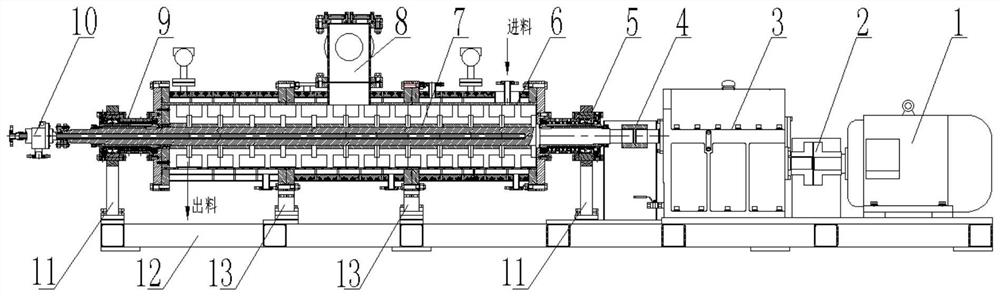

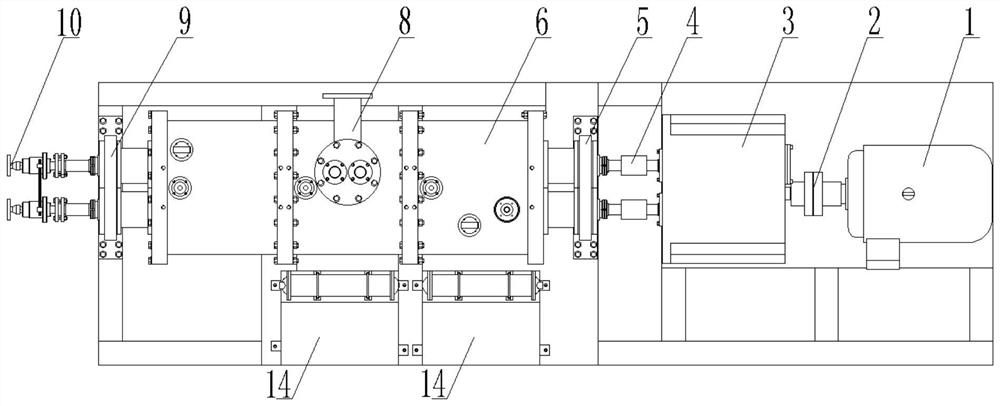

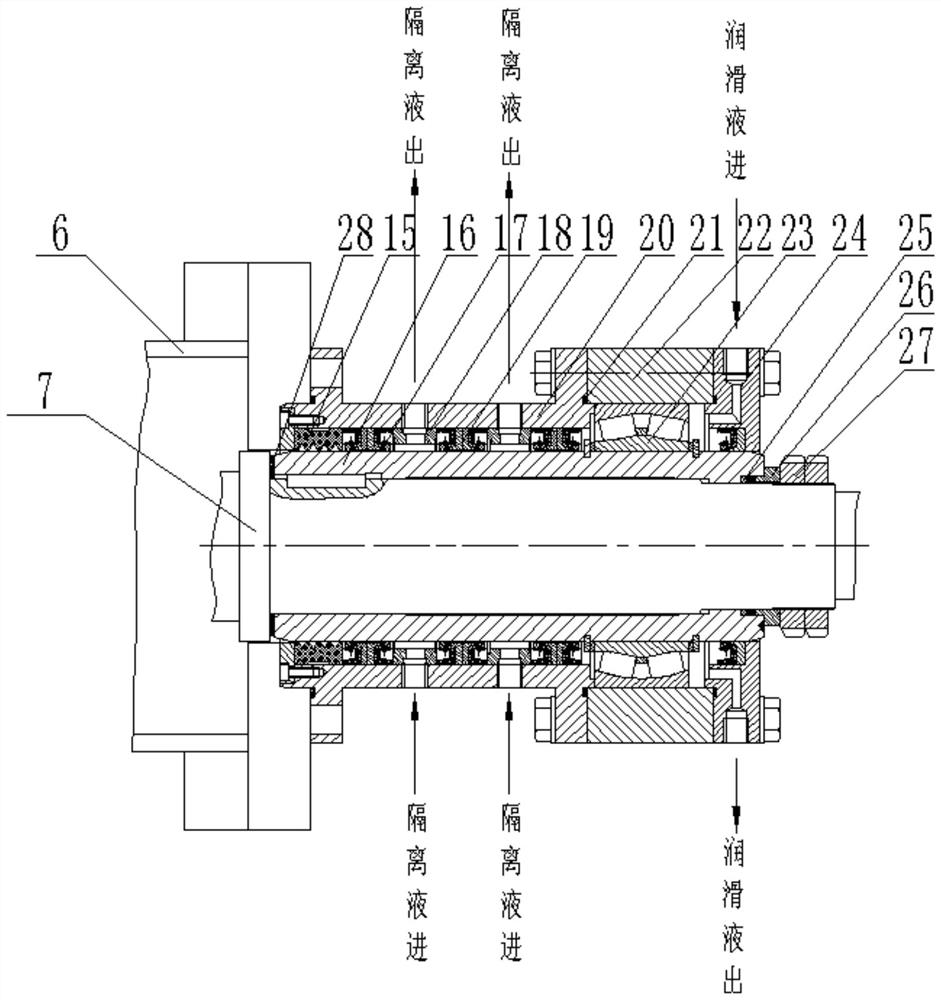

[0032] like Figure 1-9 As shown in the figure, a horizontal double-shaft kneading and devolatilizing machine includes a frame 12, a cylinder support assembly 13 is arranged above the frame 12, and a cylinder assembly 6 is arranged on the cylinder support assembly 13, so The cylinder assembly 6 is provided with a rotor shaft assembly 7 inside, a dynamic seal assembly hydraulic station 14 is disposed on one side of the outside, and an exhaust chamber assembly 8 is disposed above it. The material end dynamic seal assembly 5 and the discharge end dynamic seal assembly 9 are both connected to the frame 12 through the dynamic seal bracket 11, and the rotor shaft assembly 7 is provided with a rotary joint 10 near the discharge end dynamic seal assembly 9, A spline sleeve coupling 4 is provided near the feed end dynamic seal assembly 5 , and the spline sleeve coupling 4 is connected with the transmission case 3 , and the transmission case 3 is connected with the motor 1 through the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com