Wet-type vibrating-wire bipolar electrostatic coagulation deduster

A dust collector, electrostatic technology, applied in the field of wet vibrating wire dust collector, can solve the problems of weakening the condensation effect, difficult to capture dust droplets, etc., and achieve the effect of reducing the possibility of fouling, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

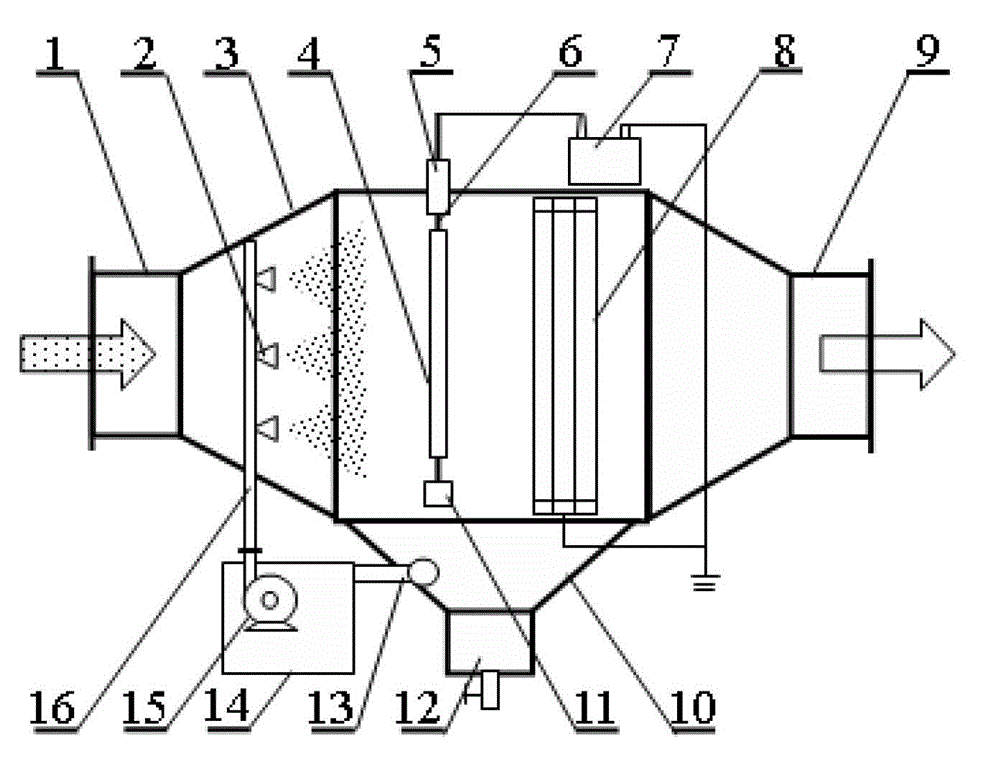

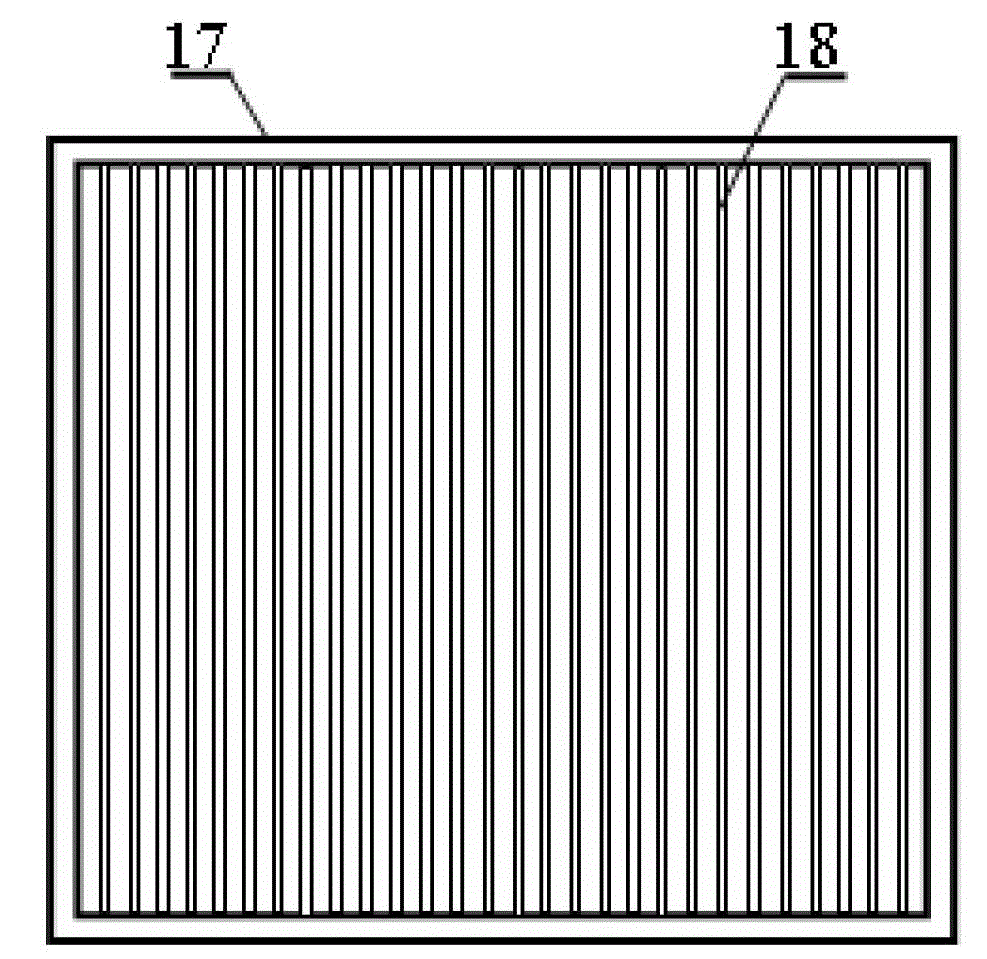

[0025] like figure 1 and figure 2 The wet-type vibrating wire bipolar electrostatic condensing and precipitator shown has a shell 3 with two ends in the shape of a prism. The bottom of the body 3 is provided with a mud bucket 10, and the bottom of the mud bucket 10 is provided with a slurry outlet 12. The mud bucket 10 is connected to the sedimentation tank 14 through the overflow pipe 13, and the water pump 15 is arranged in the sedimentation tank 14, and the water pump 15 is connected to the atomizing nozzle 2 through the circulating liquid pipe network 16, and the atomizing nozzle 2 is arranged in the housing 3 and is located in the inlet On the intake channel of the trachea 1. A single-layer vibrating wire grid 4 and a multi-layer vibrating wire grid 8 are sequentially arranged in the housing 3 between the atomizing nozzle 2 and the air outlet pipe 9 . The single-layer vibrating wire grid 4 is connected to the high-voltage pole of the DC high-voltage power supply 7 , ...

Embodiment 2

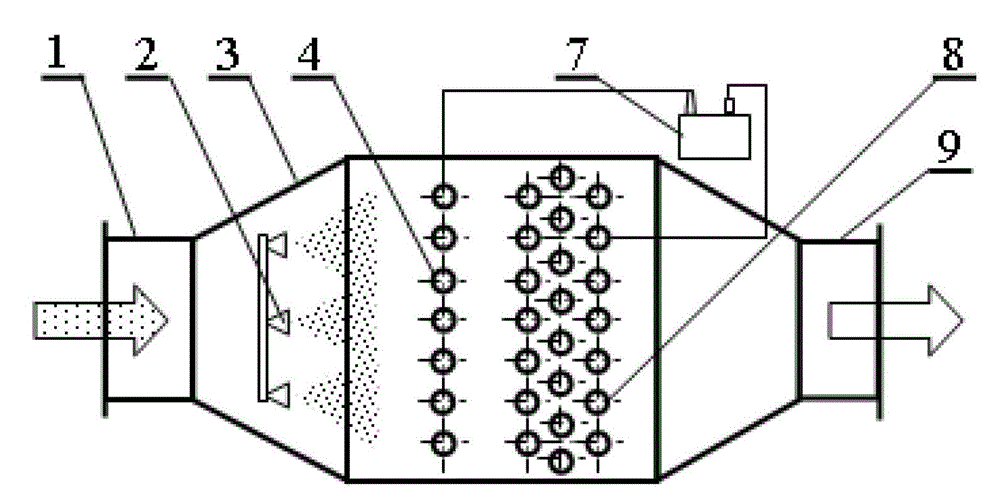

[0031] The main structure and working principle of embodiment 2 and embodiment 1 are basically the same, the only difference is that there are two sets of single-layer vibrating wire grids 4 and multi-layer vibrating wire grids 8 that cooperate with each other, two groups of single-layer vibrating wire grids 4 and The multi-layer vibrating wire grids 8 are arranged in series in sequence, and its structure is as follows Figure 4 shown. Embodiment 2 is suitable for the situation where the concentration of polluting gas is very high, and the dust cannot be fully removed and purified only through a set of single-layer vibrating wire grids 4 and multi-layer vibrating wire grids 8 . In this way, after the polluted gas is processed through the first set of single-layer vibrating wire grids 4 and multi-layer vibrating wire grids 8, the untrapped ultrafine particles pass through the second set of single-layer vibrating wire grids 4 and multi-layer vibrating wire grids 8 It is capture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com