Solvent-type super-weather-proof exterior wall coating and preparation method thereof

An exterior wall coating and super-weather-resistant technology, applied in the direction of coating, etc., can solve the problems of poor weather resistance, inability to construct, easy yellowing, etc., and achieve the effect of excellent washing resistance, good low-temperature drying performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

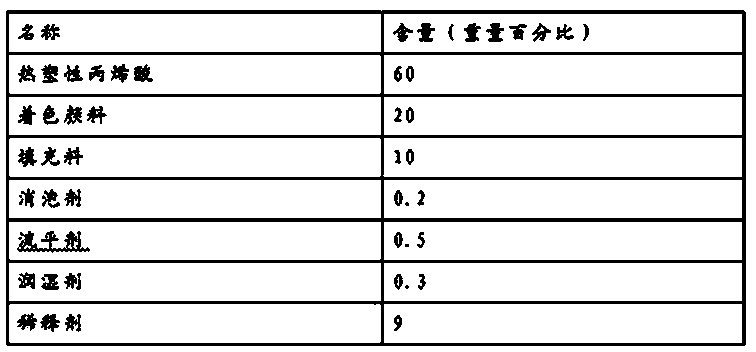

[0022] The formula ratio of this solvent-based super weather-resistant exterior wall paint is:

[0023]

[0024] Its preparation method is:

[0025] A, thermoplastic acrylic resin is dropped in the reactor;

[0026] B. Start the mixer and add a part of diluent, dispersant, and wetting agent to the reaction kettle in sequence at a stirring speed of 200-500 rpm for stirring, and stir for more than 10 minutes until the materials are evenly mixed to obtain a mixture;

[0027] C. Add colored pigments and fillers to the mixture obtained in step B successively at a stirring speed of 200-500 rpm, and then stir at a speed of 1000-1200 rpm for more than 15 minutes;

[0028] D. After stirring evenly, grind with a horizontal sand mill, and stop when the fineness is below 50 microns;

[0029] E. After the fineness meets the requirements, continue to stir at a stirring speed of 200-500 rpm, and slowly add defoamer and stir until uniform;

[0030] F. Add the remaining diluent to adjust...

Embodiment 2

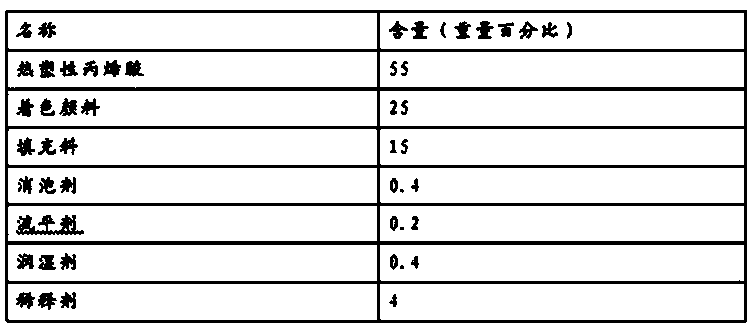

[0032] Solvent-based super weather-resistant exterior wall paint, its formula ratio is:

[0033]

[0034] Its preparation method is:

[0035] A, thermoplastic acrylic resin is dropped in the reactor;

[0036] B. Start the mixer and add a part of diluent, dispersant, and wetting agent to the reaction kettle in sequence at a stirring speed of 200-500 rpm for stirring, and stir for more than 10 minutes until the materials are evenly mixed to obtain a mixture;

[0037] C. Add colored pigments and fillers to the mixture obtained in step B successively at a stirring speed of 200-500 rpm, and then stir at a speed of 1000-1200 rpm for more than 15 minutes;

[0038] D. After stirring evenly, grind with a horizontal sand mill, and stop when the fineness is below 50 microns;

[0039] E. After the fineness meets the requirements, continue to stir at a stirring speed of 200-500 rpm, and slowly add defoamer and stir until uniform;

[0040] F. Add the remaining diluent to adjust the vi...

Embodiment 3

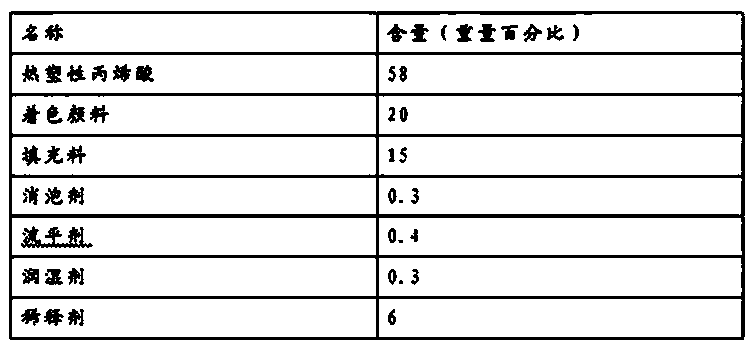

[0042] Solvent-based super weather-resistant exterior wall paint, its formula ratio is:

[0043]

[0044] Its preparation method is:

[0045] A, thermoplastic acrylic resin is dropped in the reactor;

[0046] B. Start the mixer and add a part of diluent, dispersant, and wetting agent to the reaction kettle in sequence at a stirring speed of 200-500 rpm for stirring, and stir for more than 10 minutes until the materials are evenly mixed to obtain a mixture;

[0047] C. Add colored pigments and fillers to the mixture obtained in step B successively at a stirring speed of 200-500 rpm, and then stir at a speed of 1000-1200 rpm for more than 15 minutes;

[0048] D. After stirring evenly, grind with a horizontal sand mill, and stop when the fineness is below 50 microns;

[0049] E. After the fineness meets the requirements, continue to stir at a stirring speed of 200-500 rpm, and slowly add defoamer and stir until uniform;

[0050] F. Add the remaining diluent to adjust the vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com