Self-cleaning coating for solar photovoltaic panel, and preparation method and using method of self-cleaning coating

A solar photovoltaic panel and self-cleaning technology, applied in the field of materials, can solve the problems of restricting the application and promotion of self-cleaning materials, high cost of cleaning methods, and high product cost, and achieve the effects of easy operation, good economic benefits, and no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

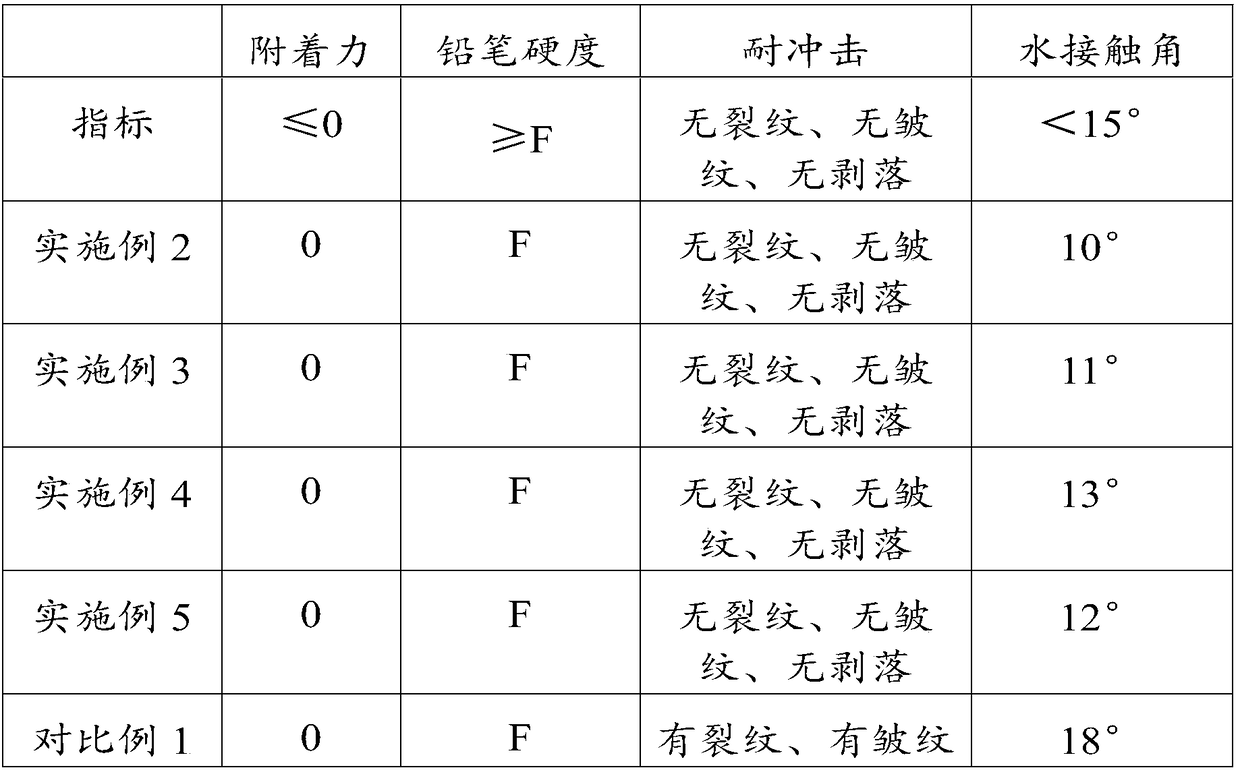

Examples

preparation example Construction

[0027] During the preparation of paint, foam is not conducive to the uniform distribution of paint, which in turn affects the self-cleaning effect of paint. Adding a defoamer suppresses foam generation and eliminates foam that has already occurred. In the embodiment of the present invention, the defoamer includes any one or at least two of BYK-066N, BYK-052, and BYK-141.

[0028] TiO 2 The mixed reaction of nanoparticles with additives and solvents makes the prepared self-cleaning coating for solar photovoltaic panels have better self-cleaning ability, light transmission performance, adhesion and durability, and can effectively clean photovoltaic panels under various environmental conditions. cleanliness. It also has the characteristics of low energy consumption, easy operation, high degree of cleanliness, and no secondary pollution, and has broad application prospects.

[0029] Further, in a preferred embodiment of the present invention, by weight percentage, when TiO 2 W...

Embodiment 1

[0037] This embodiment provides a TiO 2 Nanoparticles are mainly prepared by the following steps:

[0038] Mix ethyl titanate and absolute ethanol, and vigorously stir at 2000r / min for 60min. After rotary evaporation, add HCl and HNO 3 , adjusted the pH to 3.0, heated at 80°C for 3 hours, then heated at 160°C for 8h, and dried at 80°C to obtain TiO 2 nanoparticles

Embodiment 2

[0040] This embodiment provides a self-cleaning coating for solar photovoltaic panels, which is mainly prepared through the following steps:

[0041] By weight percentage, get the TiO that embodiment 1 provides 2 0.4 parts of nanoparticles, 1 part of BYK-310 leveling agent, 1 part of BYK-110 dispersant, 1 part of BYK-066N defoamer, 35 parts of ethanol.

[0042] TiO 2 Mix the nanoparticles with ethanol, then stir for 300min at room temperature with a speed of 400r / min; add leveling agent, dispersant and defoamer to the above mixture, and stir at room temperature with a speed of 450r / min 700min, to obtain the self-cleaning coating of the solar photovoltaic panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com