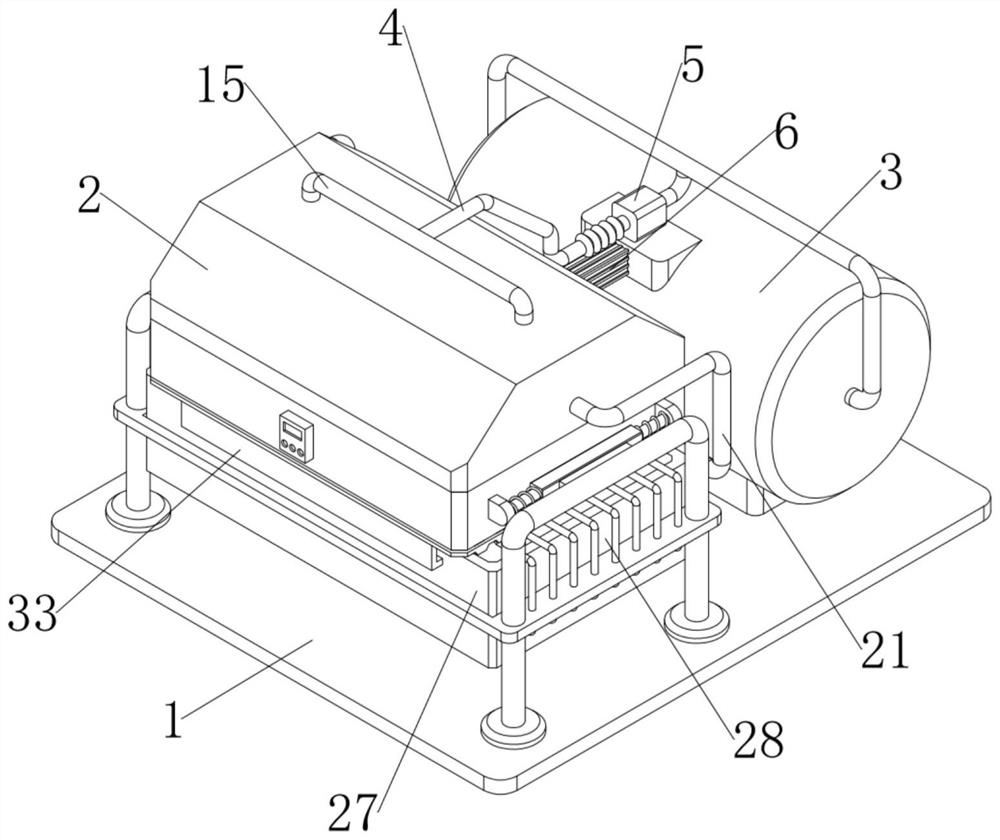

Raw material screening device for PE water supply pipe production and manufacturing

A technology of screening device and water supply pipe, which is applied in the fields of filter screen, solid separation, chemical instruments and methods, etc., can solve the problems of large screening device, time-consuming and laborious replacement of screen mesh, etc., and achieve the effect of reducing the discharge speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

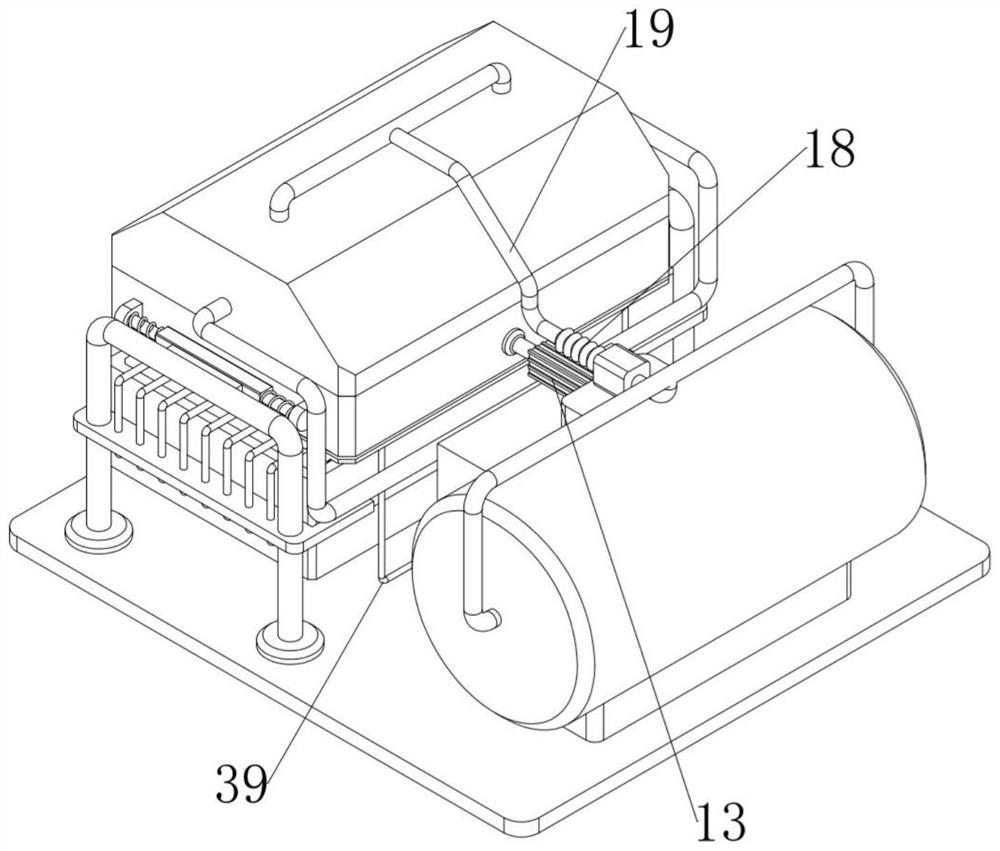

[0037] Example 1: The polyethylene particles are screened by coating type blanking.

[0038] Specifically, the controller 45 controls the suction pump 16 to start, the suction pump 16 extracts the polyethylene particles inside the polyethylene particle distribution box 3 through the suction pipe 17 , and the polyethylene particles enter the feeding pipe 19 through the conveying telescopic pipe 18 Inside, the feeding pipe 19 transports the polyethylene particles into the screening box 2 for screening. At this time, the controller 45 controls the atomization motor 23 to start, and the atomization motor 23 extracts the low molecular weight additive storage box 22 through the atomization pipe 24. Internal low molecular weight additives, low molecular weight can reduce the force between macromolecular chains, reduce the melt viscosity, and reduce the viscous fluidization temperature. Inside the pipe 26, the shunt pipe 26 sprays the low-molecular-weight additive into the screening b...

Embodiment 2

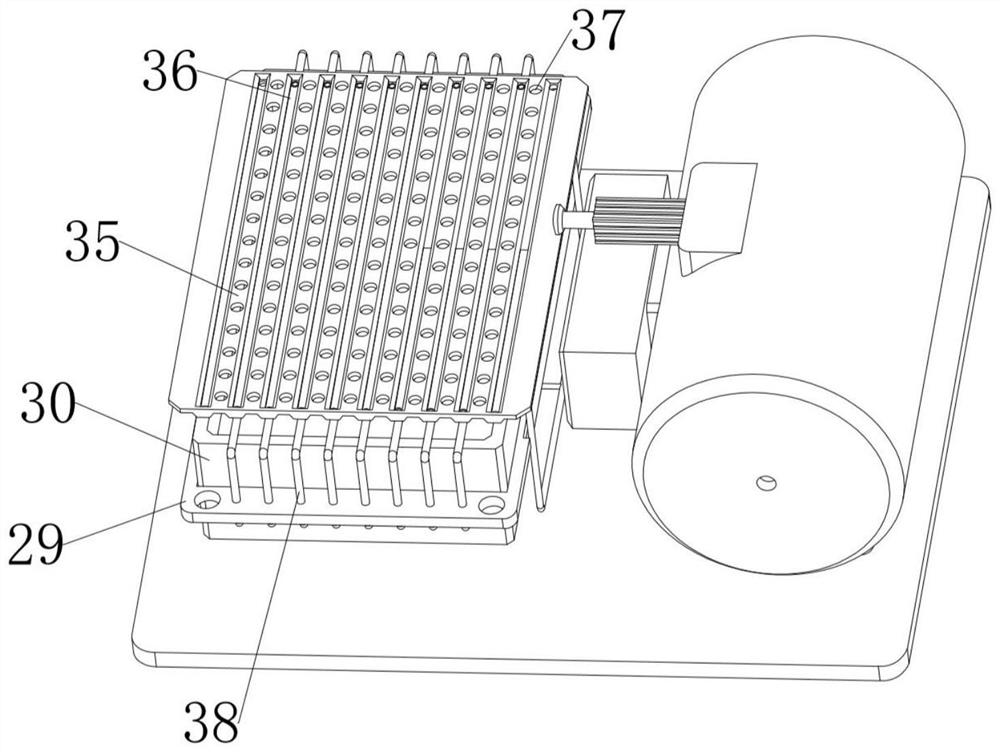

[0039] Embodiment 2, based on the above-mentioned embodiment, separate discharge of polyethylene particles is carried out.

[0040]Specifically, the controller 45 controls the heating rod 41 to start, the heating rod 41 heats the air inside the heating box 40 , the temperature inside the heating box 40 increases, and the heat is conducted into the storage copper plate 42 through the storage copper column 43 and the heat conduction copper column 44 respectively. And the inside of the melted copper corrugated board 35, the temperature of the melted copper corrugated board 35 and the storage copper board 42 rises to melt and filter the polyethylene particles, and the polyethylene particles fall into the material opening 37 through the unloading port 20, and the smaller polyethylene The particles directly fall into the upper wall of the thermal insulation board 31 through the material opening 37 for storage, while the larger polyethylene particles are melted under the action of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com