Down flocculus production equipment for solving non-spinnability of down

A production equipment and down technology, applied in material forming presses, manufacturing tools, presses, etc., can solve the problems of down non-spinning, unfavorable flexible production, etc., and achieve the effect of improving efficiency and quality, and flexible production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

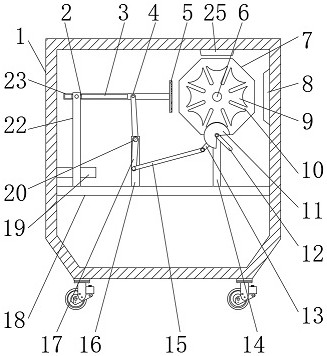

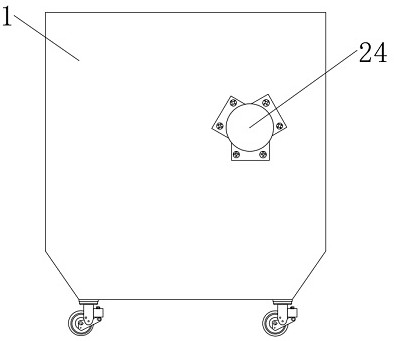

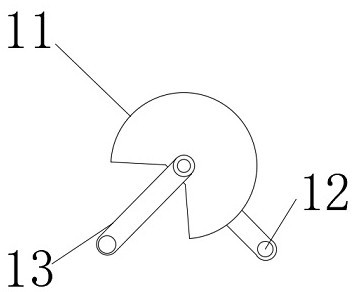

[0027] like Figure 1-6 As shown in the figure, the embodiment of the present invention provides a down wadding production equipment for solving the non-spinability of down, including a constant temperature box 1, an upper base cloth placer 8, two first fixing frames 14, two second fixing frames The frame 16, the two third fixing frames 22, the fixing base 18, the raw material carrying box 19, the servo motor 24 and the rubber powder injector 25, the inside of the incubator 1 is provided with a transposition cylinder 7, and the axial center of the transposition cylinder 7 The central axis 6 is connected through the position, and one end of the central axis 6 is rotatably connected with the side wall of one of the first fixing frames 14. One end of the 14 is fixedly connected with the transmission disc 9, the outer surface of the transmission disc 9 is provided with a plurality of transmission notches 10, and the plurality of transmission notches 10 are distributed in an annula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com