High-composite-strength multi-layer thermal insulation material and application

A multi-layer heat insulation material and composite strength technology, applied in the direction of layered products, metal layered products, glass/slag layered products, etc., can solve the problems of woven body damage, woven body and non-woven body are not easy to compound, etc. Achieve the effects of improving weaving strength, increasing seamability, and improving high temperature resistance and heat insulation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

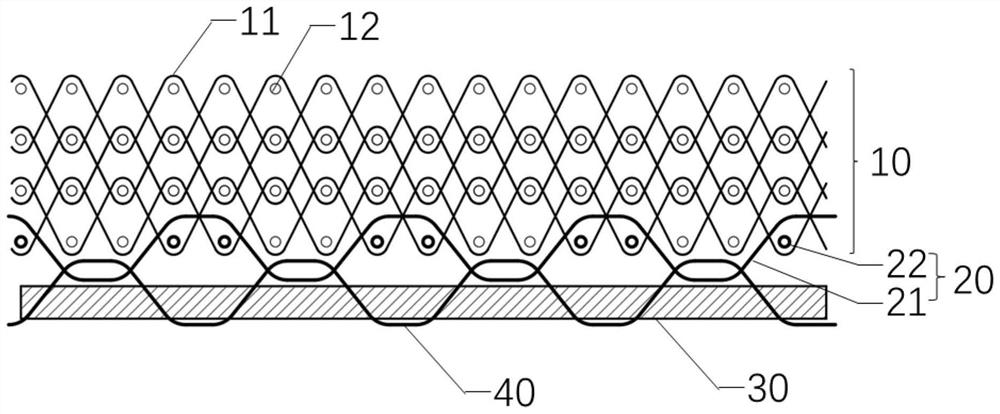

[0065] see figure 1 As shown, a stitched multi-layer functional composite material includes a knitted body stitching unit and a non-woven body unit (a first non-woven body functional layer 30) stitched and connected to one side thereof; the knitted body stitched unit includes a knitted body functional layer 10 and the stitching layer 20 arranged on one side of the knitted body functional layer 10, the stitching layer 20 is a stitching coil structure; the first stitching hole 301 runs through the thickness direction of the first non-woven body functional layer 30, and the stitching layer 20 and the first stitching Between the non-woven body functional layer 30, the suture loop and the first suture hole 301 (such as Figure 7 shown) suture connection. The adjacent two first suture holes 301 are distributed in a trapezoid shape.

[0066] The sutured weft yarns 22 and the outermost high temperature resistant weft yarns 12 of the braided functional layer 10 are arranged in a 2:2 ...

Embodiment 2

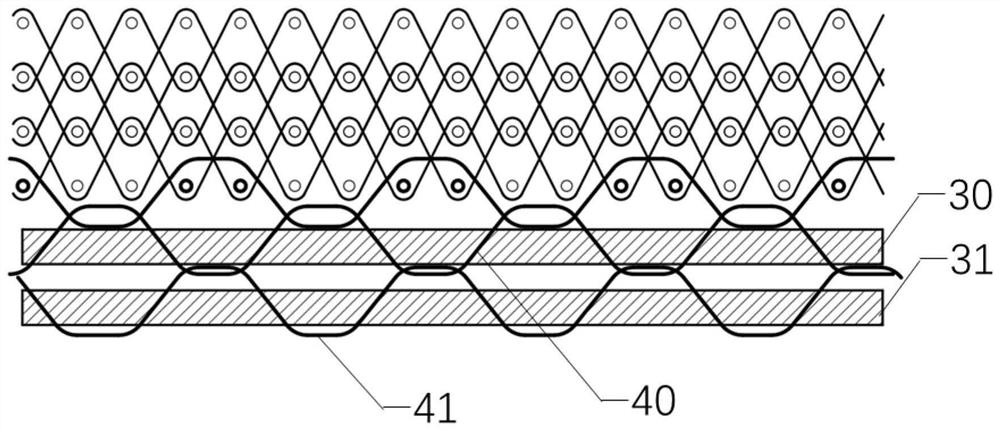

[0072] see figure 2 As shown, a stitched multi-layer functional composite material, compared with Example 1, is different in that it includes two layers of non-woven body units, namely the first non-woven body functional layer 30 and the second non-woven body respectively. In the functional layer 31, the suture holes of the second non-woven functional layer 31 are the same as those of the first non-woven functional layer 30, and the second suture 41 sequentially penetrates the suture holes and the first suture on the second non-woven functional layer 31. The thread 40 is a protruding loop of the first non-woven functional layer 30 .

[0073] The second non-woven functional layer 31 is a plurality of silicon oxide aerogel rods with a length of 50 mm and a cross-section of 3╳3 mm, and the interval between each rod is 0.5 mm.

Embodiment 3

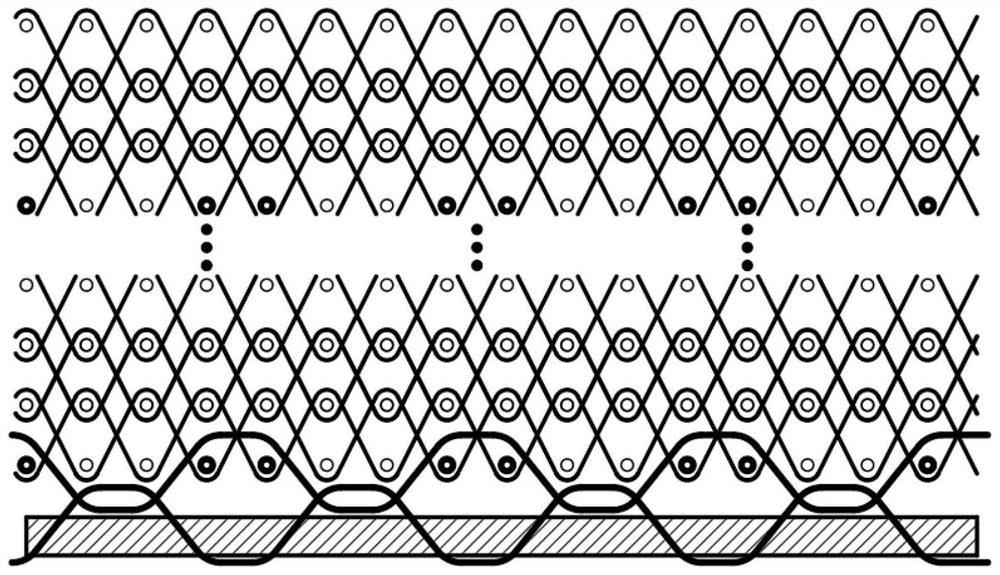

[0075] see image 3 As shown, a stitched multi-layer functional composite material, compared with Example 1, the difference is that the functional layer 10 of the braided body is a 10-layer shallow cross-bending structure. Others are substantially the same as those in Embodiment 1, and are not repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com