Anti-falling fixing device for photovoltaic module transportation

A technology for fixing devices and photovoltaic modules, applied in the directions of transportation and packaging, packaging, internal accessories, etc., can solve the problems of plastic protective film scratches, frame solar photovoltaic module damage, collisions, etc., to reduce the possibility, reduce wear, The effect of reducing the chance of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

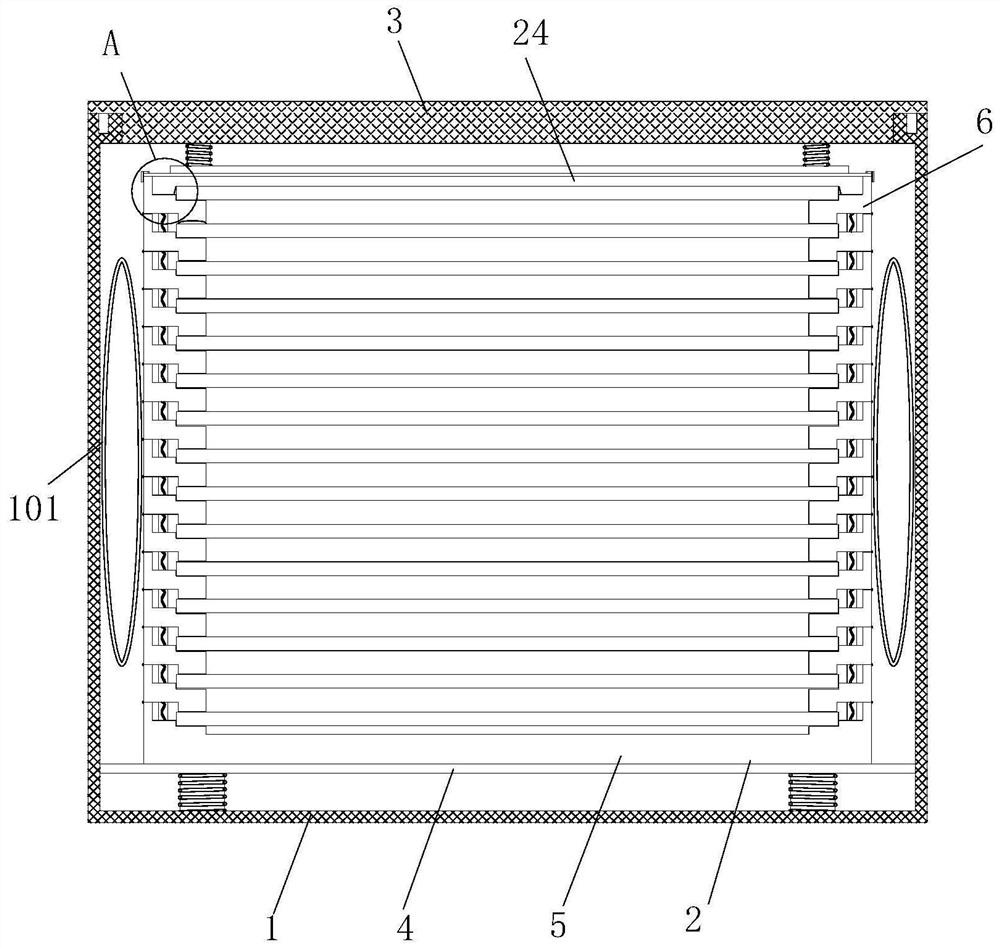

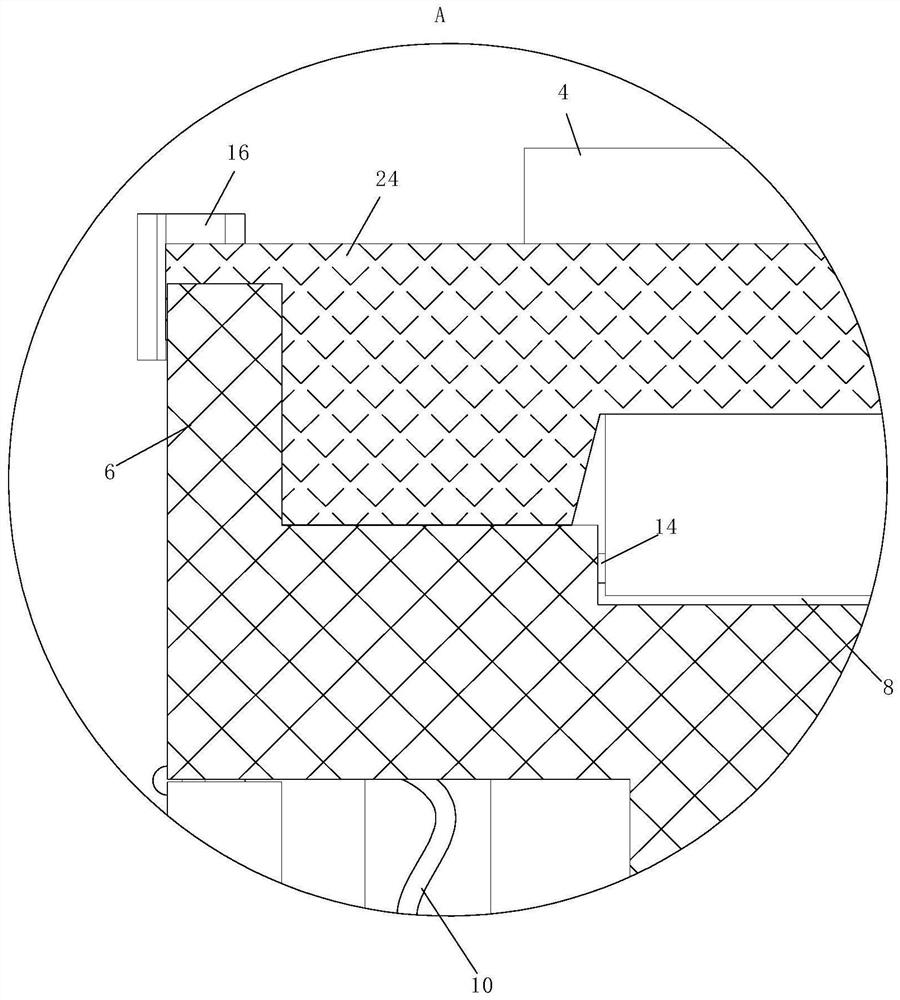

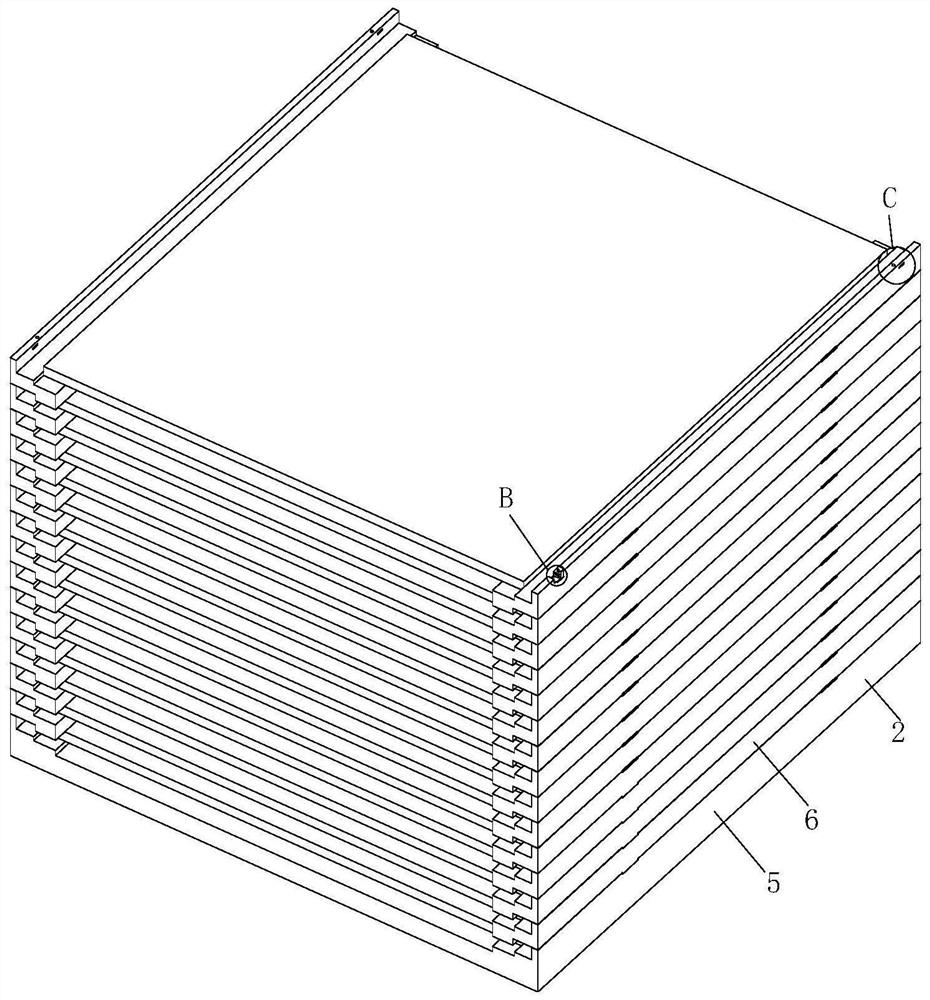

[0034]refer to figure 1 , An anti-fall fixing device for transporting photovoltaic modules, which is characterized by: comprising an outer shell 1 and an inner shell 2; the outer shell 1 is a rectangular frame body with an end cover 3, the inner bottom surface of the outer shell 1 is provided with a buffer plate 4, the buffer plate 4 is connected to the inner bottom surface of the outer shell 1 through a spring, the inner shell 2 is placed horizontally on the buffer plate 4, the outer shell 1 is provided with a waist-shaped elastic plate 101, and the elastic plate 101 is fixed on the inner side wall of the outer shell 1. The surface is also provided with a spring and a buffer plate 4, the buffer plate 4 is connected to the inner surface of the end cover 3 through a spring, and the buffer plate 4 is pressed against the upper surface of the inner shell 2; the inner shell 2 contains a plurality of photovoltaic solar panel assemblies. ; First place the photovoltaic solar panel com...

Embodiment 2

[0044] refer to Figure 10 , Comparative Example 1, as another embodiment of the present invention, a limit post 25 is arranged between the adjacent receiving plates 6, and the limit post 25 is fixed on the horizontal plane of the lower receiving plate 6; The column 25 limits the distance between the upper and lower adjacent two receiving plates 6, prevents the upper photovoltaic module from being pressed down, and causes the lower photovoltaic module to be squeezed and damaged, and adjusts the rotation connection point between the two adjacent receiving plates 6. protection to prevent it from disconnecting.

[0045] Working principle: First, place the photovoltaic solar panel components in the inner shell 2 one by one, and then place the inner shell 2 together in the outer shell 1. At this time, the inner shell 2 is placed in the center of the outer shell 1 through the buffer plate 4 and the elastic plate 101. When After the photovoltaic solar panel assembly is consigned to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com