Anti-freezing concrete and preparation method thereof

A technology of concrete and cementitious materials, which is applied in the field of building materials, can solve the problems of limited contribution to concrete frost resistance, foaming, unstable foam stability, and weak air-entraining performance, so as to improve frost resistance and improve Effect of enhancing effect, good foaming and foam stabilizing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

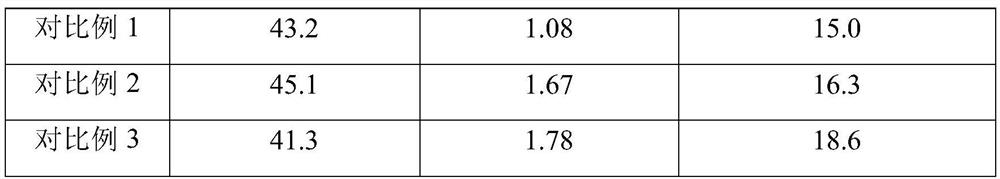

Examples

preparation example 1

[0038] A kind of air-entraining agent, its preparation method is:

[0039] S1: 40 g of phenol, 40 g of 4-nonylphenol and 0.1 g of sodium hydride are mixed and heated, and the heating temperature is 60 ° C. Then, the initial reaction product is obtained after 40 min of reaction under vacuum conditions, and the initial reaction product is mixed with 800 g of ethylene oxide. Mix, continue to heat and keep the reaction process under a certain pressure state, the reaction obtains the reaction intermediate, the initial reaction product is mixed with ethylene oxide, and then the heating temperature is 100 ℃, and the heating time is 1h; the reaction process to obtain the reaction intermediate is maintained. The pressure is 0.2Mpa.

[0040] S2: The reaction intermediate is mixed with 6g phosphoric acid and 40g o-xylene and then heated, the heating temperature is 120°C, and the heating time is 16h, the obtained product is cooled, concentrated and washed under reduced pressure to obtain ...

preparation example 2

[0042] A kind of air-entraining agent, its preparation method is:

[0043] S1: 55g of phenol, 55g of 4-nonylphenol and 4g of sodium hydride are mixed and heated, and the heating temperature is 80° C. The initial reaction product is obtained after 60 min of reaction under vacuum conditions, and the initial reaction product is mixed with 1000g of ethylene oxide , continue to heat and keep the reaction process under a certain pressure state, the reaction obtains the reaction intermediate, the initial reaction product is mixed with ethylene oxide, and the heating temperature is 120 ℃, and the heating time is 2h; the reaction process to obtain the reaction intermediate maintains the pressure is 0.3Mpa.

[0044] S2: The reaction intermediate is mixed with 12 g phosphoric acid and 50 g o-xylene, and then heated. The heating temperature is 140° C. and the heating time is 20 h. The obtained product is cooled, concentrated and washed under reduced pressure to obtain an air-entraining ag...

preparation example 3

[0046] A kind of air-entraining agent, its preparation method is:

[0047] S1: 50g of phenol, 45g of 4-nonylphenol and 2g of sodium hydride are mixed and heated, and the heating temperature is 70° C. The initial reaction product is obtained after the reaction under vacuum conditions for 50min, and the initial reaction product is mixed with 900g of ethylene oxide. , continue to heat and keep the reaction process under a certain pressure state, the reaction obtains the reaction intermediate, the initial reaction product is mixed with ethylene oxide, and then the heating temperature is 110 ℃, and the heating time is 1.5h; the reaction process of obtaining the reaction intermediate remains The pressure is 0.25Mpa.

[0048]S2: The reaction intermediate is mixed with 9 g phosphoric acid and 45 g o-xylene and heated at a heating temperature of 130° C. and a heating time of 18 h. The obtained product is cooled, concentrated and washed under reduced pressure to obtain an air-entraining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com