Spun yarn broken end automatic stop device suitable for spinning flax siro yarn

A technology of self-stopping and linen racing at broken ends, applied in textile and papermaking, fiber processing, fiber opening and cleaning, etc., can solve the problem of reducing the timeliness of broken ends detection devices, reducing the efficiency of yarn breakage wiring, and the inability to quickly separate ends. Wiring and other problems, to improve the efficiency of wiring repair, prevent breakage, and reduce randomness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

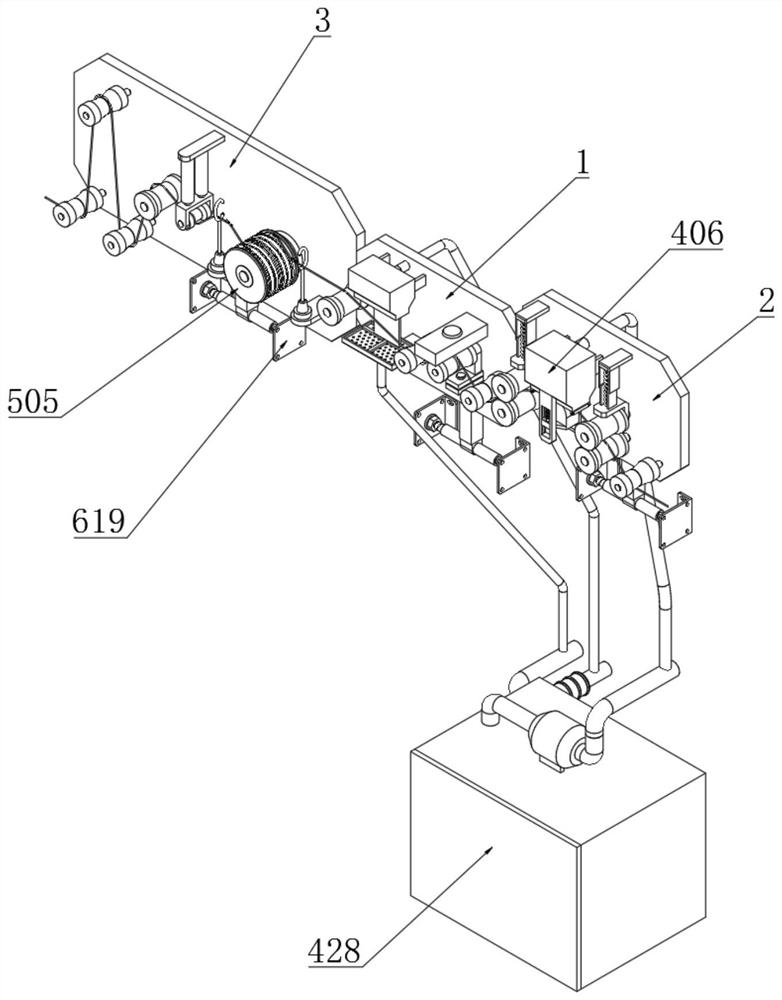

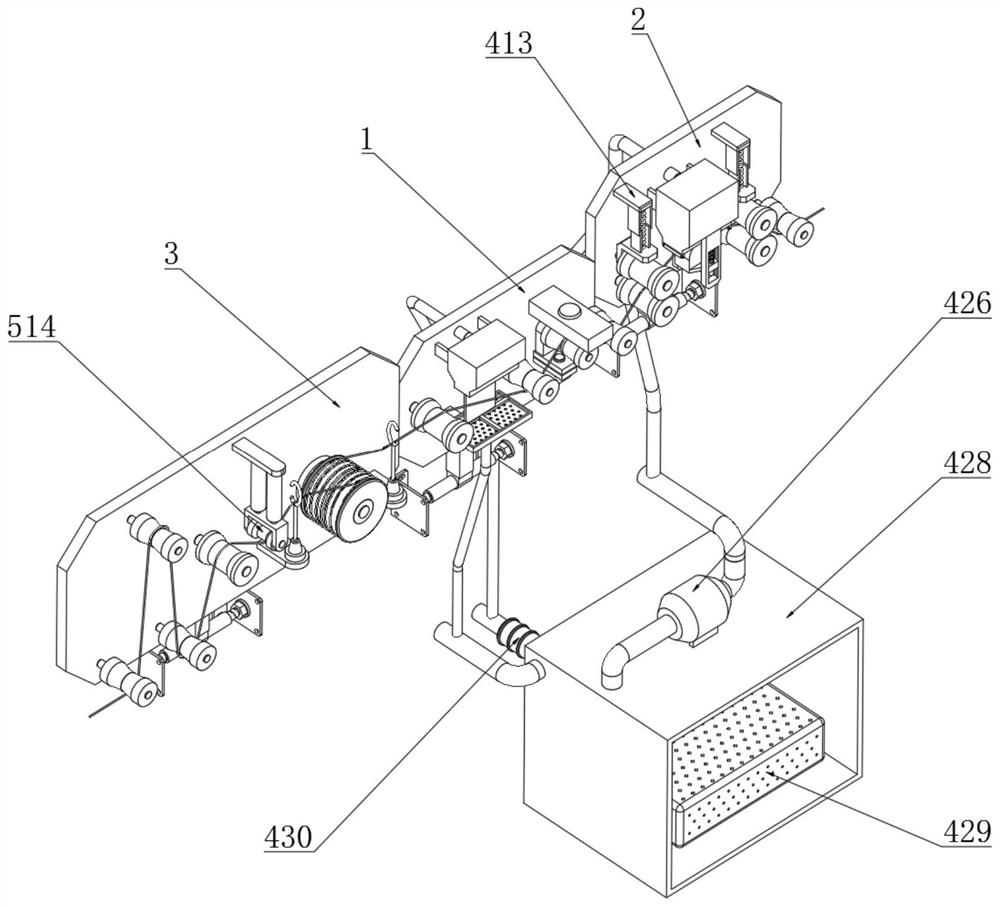

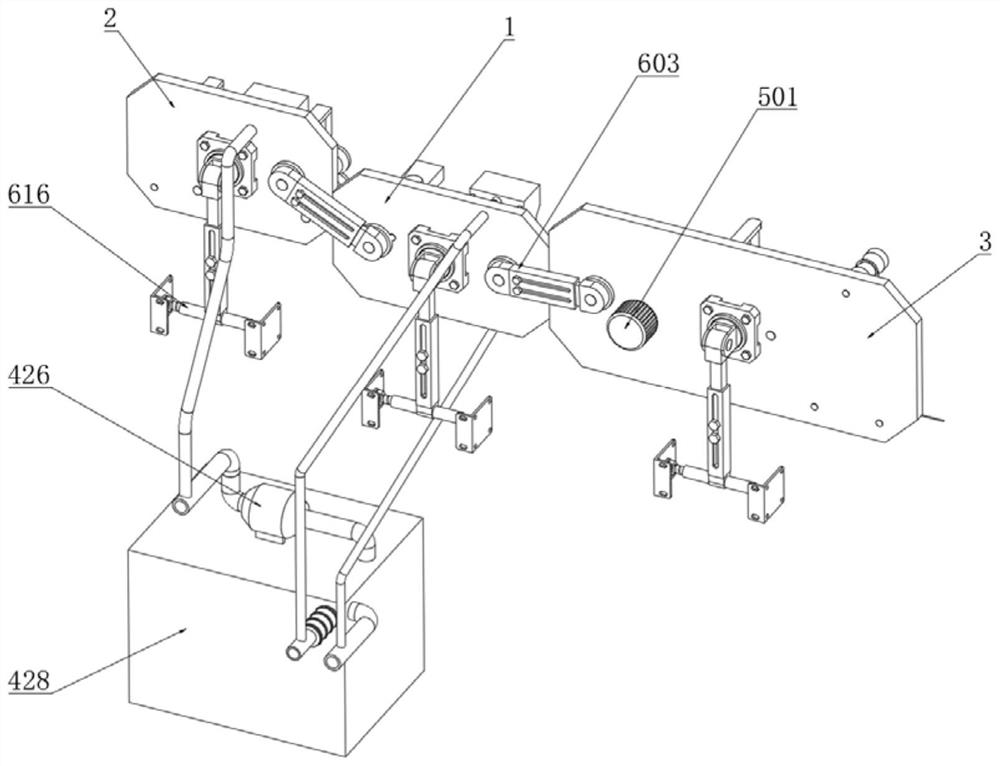

[0041] Example: as Figure 1-10 As shown in the figure, the present invention provides a technical solution, a spun yarn breakage automatic stop device suitable for spinning flax siro yarn, comprising an installation middle plate 1, one end of the installation middle plate 1 is provided with an installation front plate 2, and the installation middle plate 1 is provided on the other side. One end is provided with the installation rear plate 3;

[0042] The front side of the installation middle plate 1 is provided with a circulating pressurized end-break detection mechanism 4, which cleans the outer side of the yarn through a continuous strong airflow during the continuous running of the yarn, thereby effectively removing the short and broken fibers that are easy to fall off, and at the same time. Apply additional tension on the outside of the yarn;

[0043] The cyclic pressure detection mechanism 4 includes laser detection head 401, detection small plate 402, pressure sensor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com