Steel bridge deck pavement structure

A steel bridge deck and pavement technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of poor low-temperature cracking resistance, achieve excellent wear resistance and flexural performance, ingenious structure, and the effect of isolating moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

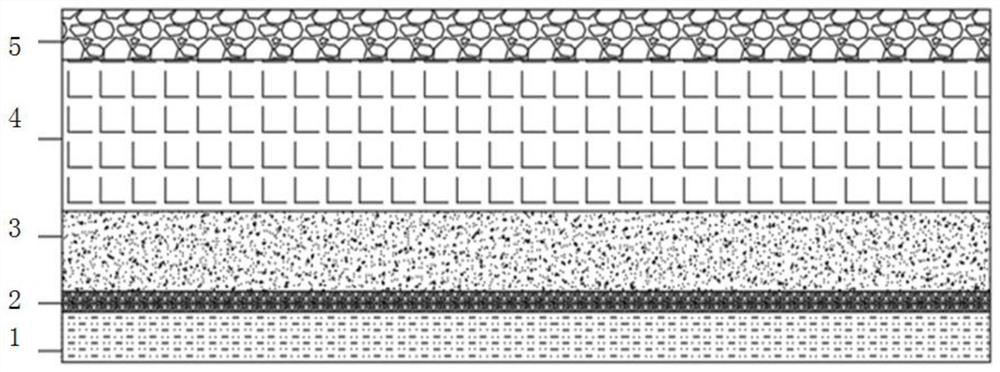

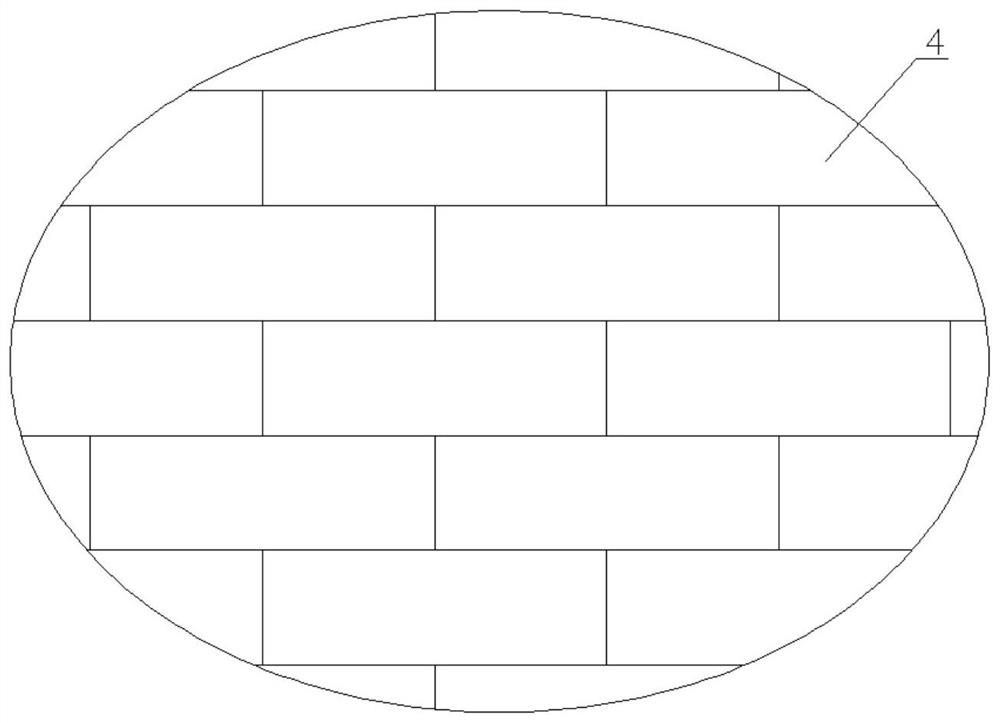

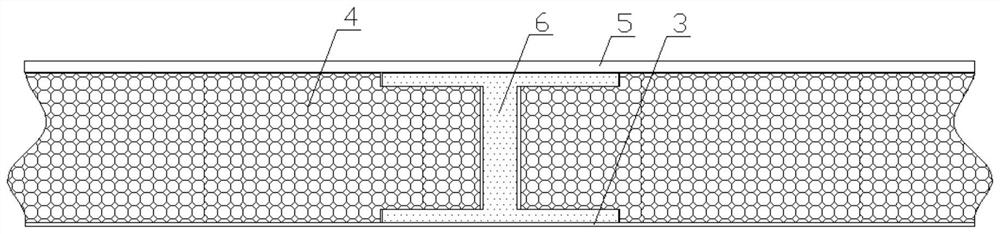

[0026] A steel bridge deck pavement structure, such as figure 1 , figure 2 and image 3 As shown, including the anti-corrosion layer 2, the elastic transition layer 3, the polymer prefabricated profile layer 4 and the anti-slip layer 5 laid on the steel bridge deck 1 (steel plate) in sequence, between the elastic transition layer 3 and the polymer prefabricated profile layer 4 There is a bonding layer (not shown in the figure); the elastic transition layer 3 and the anti-slip layer 5 both adopt an integral molding structure, and the specifications of the single polymer prefabricated profile layer 4 are 6-12 meters long and 1-1.8 meters wide. , the adjacent polymer prefabricated profile layers 4 are connected by lap joint or snap connection, and the surfaces of all the connected polymer prefabricated profile layers 4 are located on the same plane.

[0027] Among them, the elastic transition layer 3 is prepared by blending reactive resin and fillers with a particle size of le...

Embodiment 2

[0035] A steel bridge deck pavement structure, with reference to Embodiment 1 and combined with Figure 4 As shown, the main difference between it and Example 1 is: the anti-slip layer 5 is a 5mm thick modified methacrylic resin layer; the polymer prefabricated profile layer 4 is a hollow profile layer prefabricated with modified ASA, and its thickness is 40mm , the hollow ratio is 30%, the holes corresponding to the hollow parts are round holes; the thickness of the elastic transition layer 3 is 15mm.

Embodiment 3

[0037] A steel bridge deck pavement structure, referring to Example 1, the main difference between it and Example 1 is: the anti-slip layer 5 adopts a 6mm thick modified methacrylic resin layer; the polymer prefabricated profile layer 4 adopts PA alloy. The prefabricated hollow profile layer has a thickness of 30 mm, a hollow ratio of 70%, and the holes corresponding to the hollow parts are square holes; the thickness of the elastic transition layer 3 is 12 mm.

[0038] In the remaining examples, refer to implementation 1, wherein: the thickness of the anti-corrosion layer can be selected in the range of 0.05-0.8mm, the thickness of the elastic transition layer can be selected in the range of 5-10mm, and the thickness of the polymer prefabricated profile layer can be selected in the range of 30-35mm The thickness of the anti-slip layer can be selected within the range of 4-6mm; the polymer prefabricated profile layer can also be made of PVC alloy.

[0039] By adopting the stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com