Temperature point detection and adjustment system and detection and adjustment method for suction dredger

An adjustment system and adjustment method technology, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as poor immediacy, insufficient accuracy, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present application will be preferably described below with reference to the accompanying drawings and embodiments.

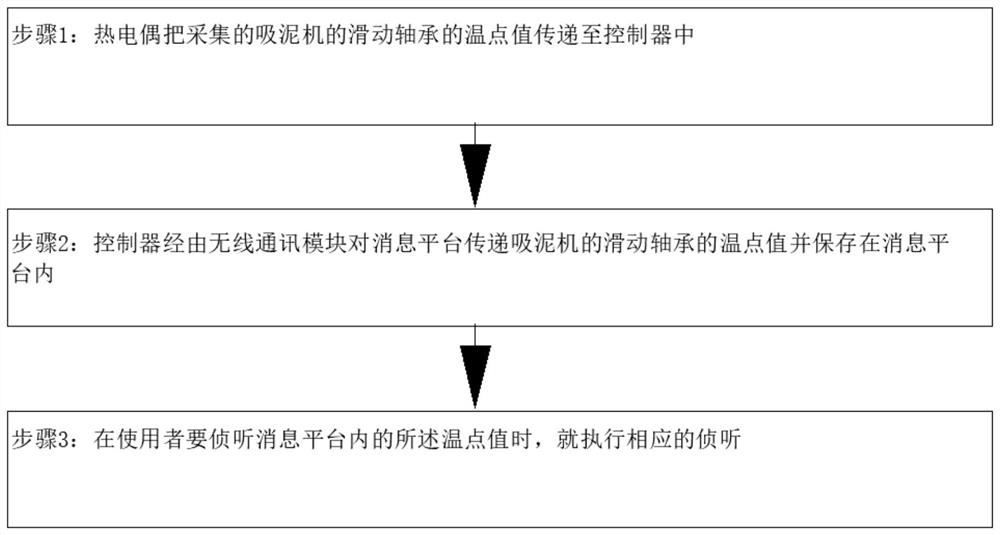

[0056] like Figure 1-Figure 5 As shown, the temperature point detection and adjustment system for the suction dredger includes:

[0057] A thermocouple is set on the sliding bearing of the suction mud machine, the thermocouple is connected to the controller, and the controller is connected to the wireless communication module. The controller is connected to the message platform in the wireless network through the wireless communication module, and the message platform is also in The client in the wireless network is connected; the controller can be a single chip or an ARM chip, the wireless communication module can be a WIFI module or a 4G module, the wireless network can be a WLAN or a 4G network, and the client and the message platform can be a PC or a laptop.

[0058] The modules running on the controller include delivery module one;

[0059] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com