Rerepaired and reinforced brick factory building structure and construction method thereof

A technology for strengthening structures and workshops, applied in truss structures, building maintenance, industrial buildings, etc., can solve the problem of no reinforcement and reuse, and achieve the effects of increasing service life, increasing bearing capacity, and improving mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

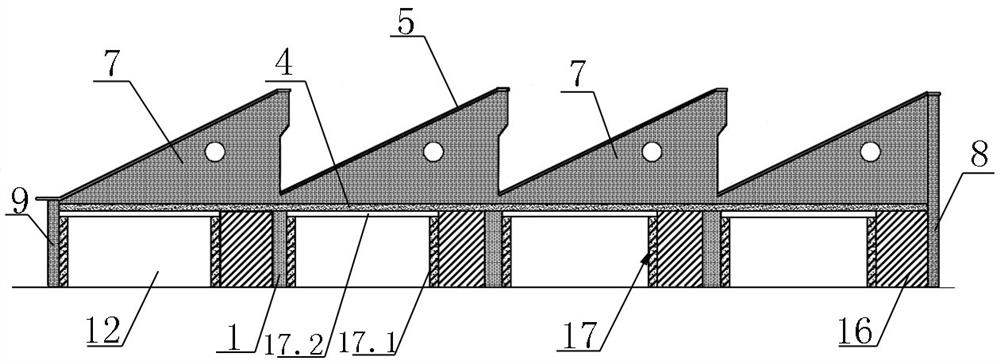

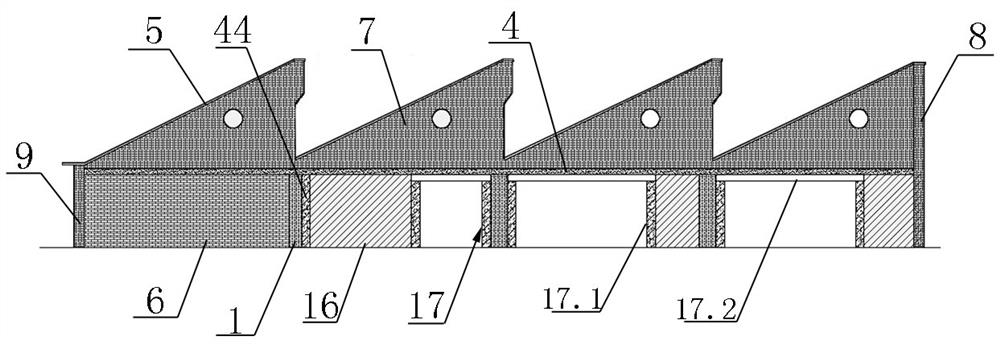

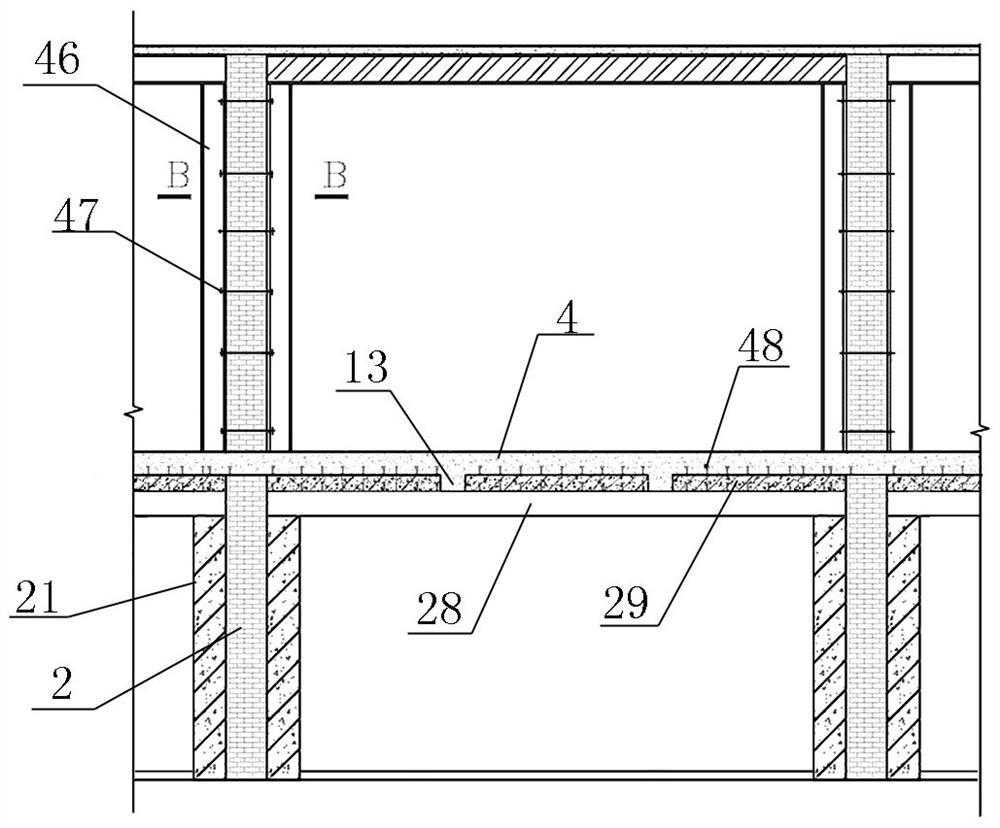

[0051] like Figure 1-16 As shown, this repaired and reinforced brick factory building structure includes a side column 1, a front-end column 2, a rear-end column 3, a ring beam 4, a single-slope roof 5 and the original brick wall 6; the side column 1 has two Group, two groups of side pillars 1 are respectively arranged at intervals along the longitudinal sides of the two sides of the brick factory structure; front corner pillars 8 and rear corner pillars 9 are respectively provided on the front and rear sides of each group of side pillars 1; The horizontal interval is arranged between the front corner columns 8 on both sides; the rear end column 3 is provided with a group, and is arranged between the rear corner columns 9 on both sides along the horizontal interval; the ring beam 4 is along the four peripheries of the brick factory structure. Lines are arranged, and the longitudinal sides of the ring beam 4 are supported on the top of the side pillars 1; connecting beams 10 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com