High-temperature well logging polar plate based on vacuum heat insulation technology

A technology of vacuum heat insulation and polar plates, which is applied in the direction of electric/magnetic detection, measurement, and measurement devices for well logging records, can solve the problems of shortened instrument life, low construction success rate, and increased cost. Upsizing, ensuring safety, and improving the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

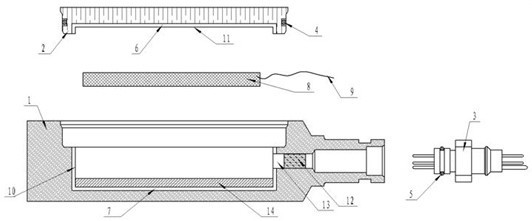

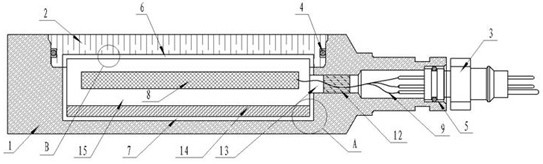

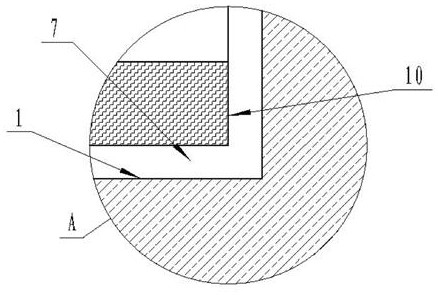

[0047] like figure 1 As shown, a high-temperature logging electrode plate based on vacuum insulation technology includes a base shell 1, a base vacuum layer 7 and a base inner tank 10, the base shell 1 is welded with a base inner tank 10, the base shell 1 and the base inner tank 10 are welded A base vacuum layer 7 is formed between the bladders 10 , and the base consists of a base shell 1 , a base inner bladder 10 and a base vacuum layer 7 .

[0048] In this embodiment, as Figure 1-2 As shown in the figure, in order to further improve the sealing effect on the base and the upper cover, an upper cover shell 2 is arranged above the base shell 1, the surface of the upper cover shell 2 is welded with an upper cover inner tank 11, and the upper cover shell 2 and the upper cover An upper cover vacuum layer 6 is formed between the gallbladders 11. The upper cover is composed of an upper cover outer shell 2, an upper cover inner gallbladder 11 and an upper cover vacuum layer 6. The ...

Embodiment 3

[0050] like figure 1 As shown, a high-temperature logging electrode plate based on vacuum insulation technology includes a base shell 1, a base vacuum layer 7 and a base inner tank 10, the base shell 1 is welded with a base inner tank 10, the base shell 1 and the base inner tank 10 are welded A base vacuum layer 7 is formed between the bladders 10 , and the base consists of a base shell 1 , a base inner bladder 10 and a base vacuum layer 7 .

[0051] The difference between this embodiment and the above-mentioned embodiment is that:

[0052] In this embodiment, as Figure 1-4 As shown in the figure, in order to further improve the effect of reducing heat conduction, a wire channel 13 for placing the wire 9 is opened inside the base shell 1. The interior of the wire channel 13 is filled with an insulator 12, and the wire 9 passes through the wire channel 13. Or the circuit module 8 is connected with the pins on the pressure-bearing plug 3 to establish an electrical connection ...

Embodiment 4

[0054] like figure 1 As shown, a high-temperature logging electrode plate based on vacuum insulation technology includes a base shell 1, a base vacuum layer 7 and a base inner tank 10, the base shell 1 is welded with a base inner tank 10, the base shell 1 and the base inner tank 10 are welded A base vacuum layer 7 is formed between the bladders 10 , and the base consists of a base shell 1 , a base inner bladder 10 and a base vacuum layer 7 .

[0055] The difference between this embodiment and the above-mentioned embodiment is that:

[0056] In this embodiment, as Figure 1-4 As shown, in order to further improve the temperature stabilization effect, the interior of the base inner tank 10 is provided with a heat absorbing body 14, the heat absorbing body 14 is made of a phase-change constant temperature material, and the front end of the heat absorbing body 14 is connected with a circuit module 23; A plate inner cavity 15 is formed between the base liner 10 and the sensor or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com