Connector, lattice unit cell and assembled lattice structure

A connecting head and lattice technology, which is applied in the direction of connecting members, rod connections, building elements, etc., can solve problems such as low connection efficiency, and achieve the effects of improving production efficiency, reducing connection difficulty, and increasing connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

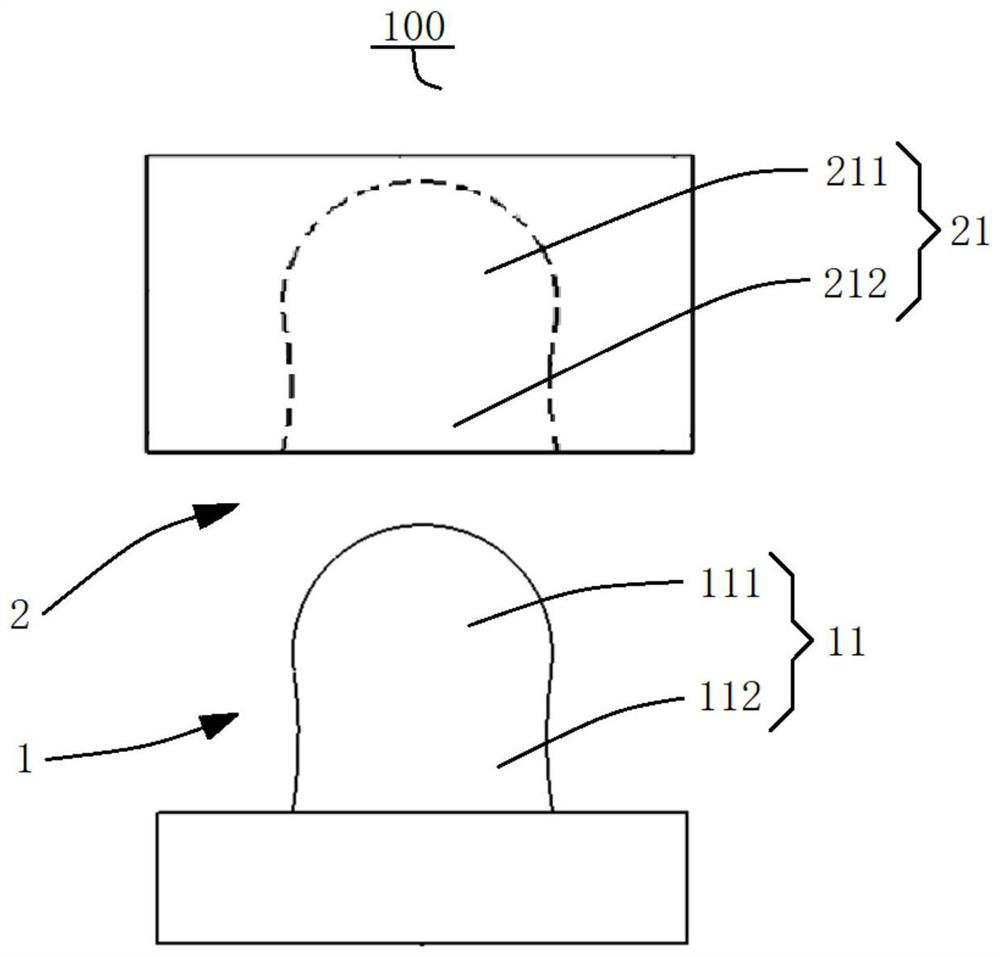

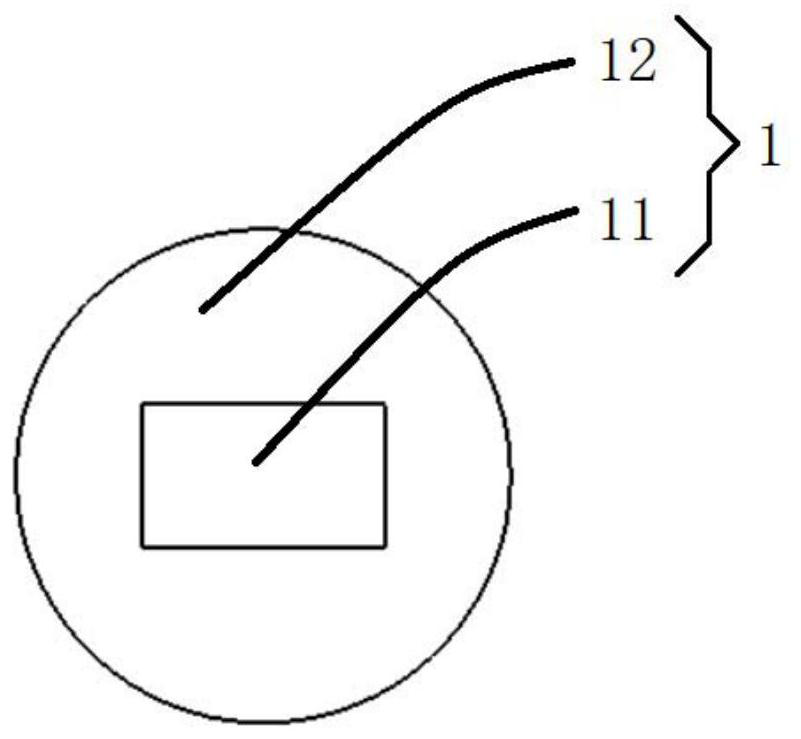

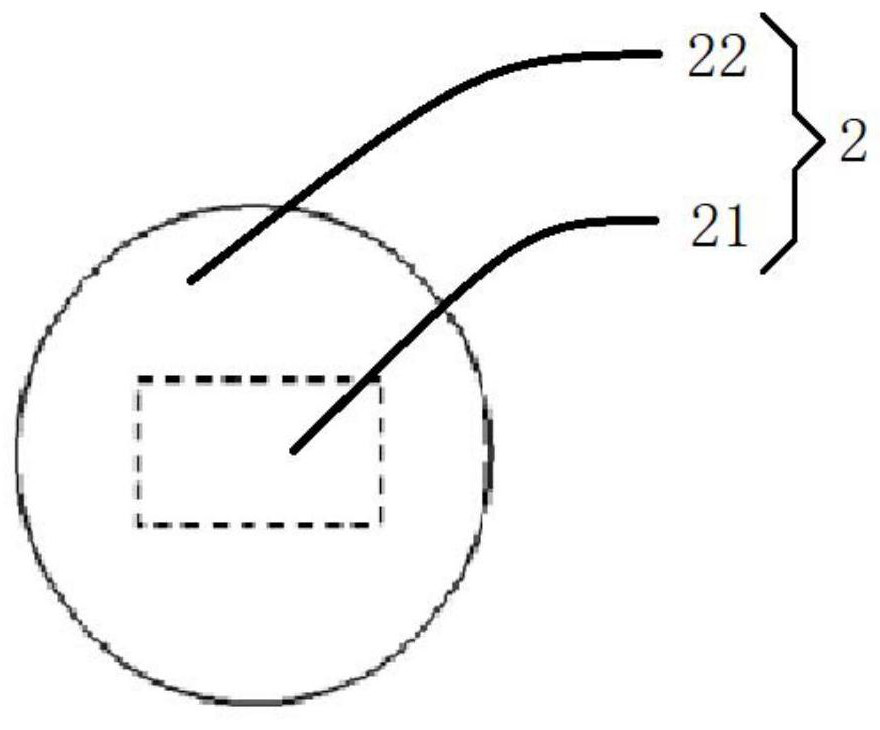

[0105] A connector 100, such as figure 1 As shown, it includes: a first connecting part 1 and a second connecting part 2 .

[0106] Wherein, one of the first connecting part 1 and the second connecting part 2 is provided with a protruding part 11, while the other is provided with a connecting groove 21, and the protruding part 11 can be connected with the connecting groove 21 to make the first connecting part 1 and the second connecting part 2 are connected.

[0107] like figure 1 As shown, the protruding portion 11 includes a pressing portion 111 and a necking portion 112 , and one end of the pressing portion 111 is connected to the necking portion 112 .

[0108] like figure 1 As shown, the connecting groove 21 includes a first connecting groove 211 and a second connecting groove 212 that communicate with each other. When the direction of the connecting groove 211 moves, the pressing portion 111 presses the groove wall of the second connecting groove 212 ;

Embodiment 2

[0110] A connector 100 is different from Embodiment 1 in that, on the basis of Embodiment 1, the extruded portion 111 and the necked portion 112 are flat structures, and at least part of the extruded portion 111 has a larger cross-sectional width than the necked portion. 112 The width of the cross section.

[0111] like image 3 As shown, the first end surface 1111 of the extruding portion 111 and the two second end surfaces 1121 of the necking portion 112 are both arc surfaces, and both sides of the first end surface 1111 are respectively connected with a second end surface 1121. Different from the curvature of the second end surface 1121 .

[0112] like image 3 As shown, the two second end surfaces 1121 are arranged symmetrically with the central axis of the first end surface 1111 as the axis, and the first end surface 1111 and the second end surface 1121 intersect at the same horizontal plane to form a first circular arc line and two second circular arc lines , the line...

Embodiment 3

[0114] A connector 100 is different from Embodiment 1 in that, on the basis of Embodiment 1, such as Image 6 As shown, at least one elastic protrusion 213 is formed in the connecting groove 21 to protrude inwardly, and the corresponding elastic protrusion 213 is provided with a corresponding avoidance hole 113 on the protrusion 11. When the protrusion 11 is connected to the connecting groove 21, The elastic protrusions 213 are matched with the avoidance holes 113 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com